Production process for middle-width hot rolling strip steel for cold rolling

A production process and wide-band steel technology, applied in the field of hot rolling in the metallurgical industry, can solve problems affecting economic interests, high grain size, difficulties, etc., and achieve the effect of improving product mechanical properties and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below by embodiment.

[0020] A production process of hot-rolled medium and wide strip steel for cold rolling, including converter, refining, continuous casting, hot rolling, the converter is a 60-ton converter, the refining is an LF refining furnace, and the rolling mill is an 850 rolling mill. The specific process flow is:

[0021] 60t converter → LF furnace → continuous casting → heating → descaling → rough rolling → finishing rolling → laminar cooling → coiling

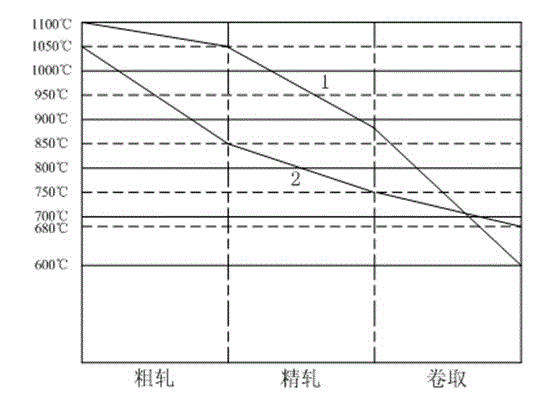

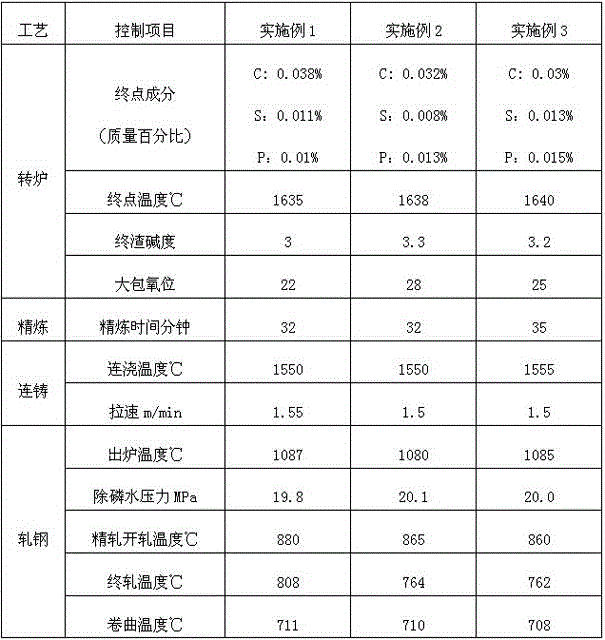

[0022] Refer to attached figure 1 Curve 2, process parameters control as shown in Table 1:

[0023] Table 1 Process control table of hot-rolled strip steel for cold rolling

[0024]

[0025] The mechanical test results of the product are shown in Table 2 and Table 3

[0026] Table 2 Mechanical properties of hot-rolled steel strip

[0027] mechanical properties Tensile strength MPa Lower yield strength MPa Elongation after break % Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com