Marine-splash-zone-simulating corrosion test device and testing method

A technology of corrosion test and splash zone, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as uneven spraying of samples, analysis of unfavorable test results, deviation of sample results, etc., and achieve manufacturing Low operating cost, convenient test method, and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

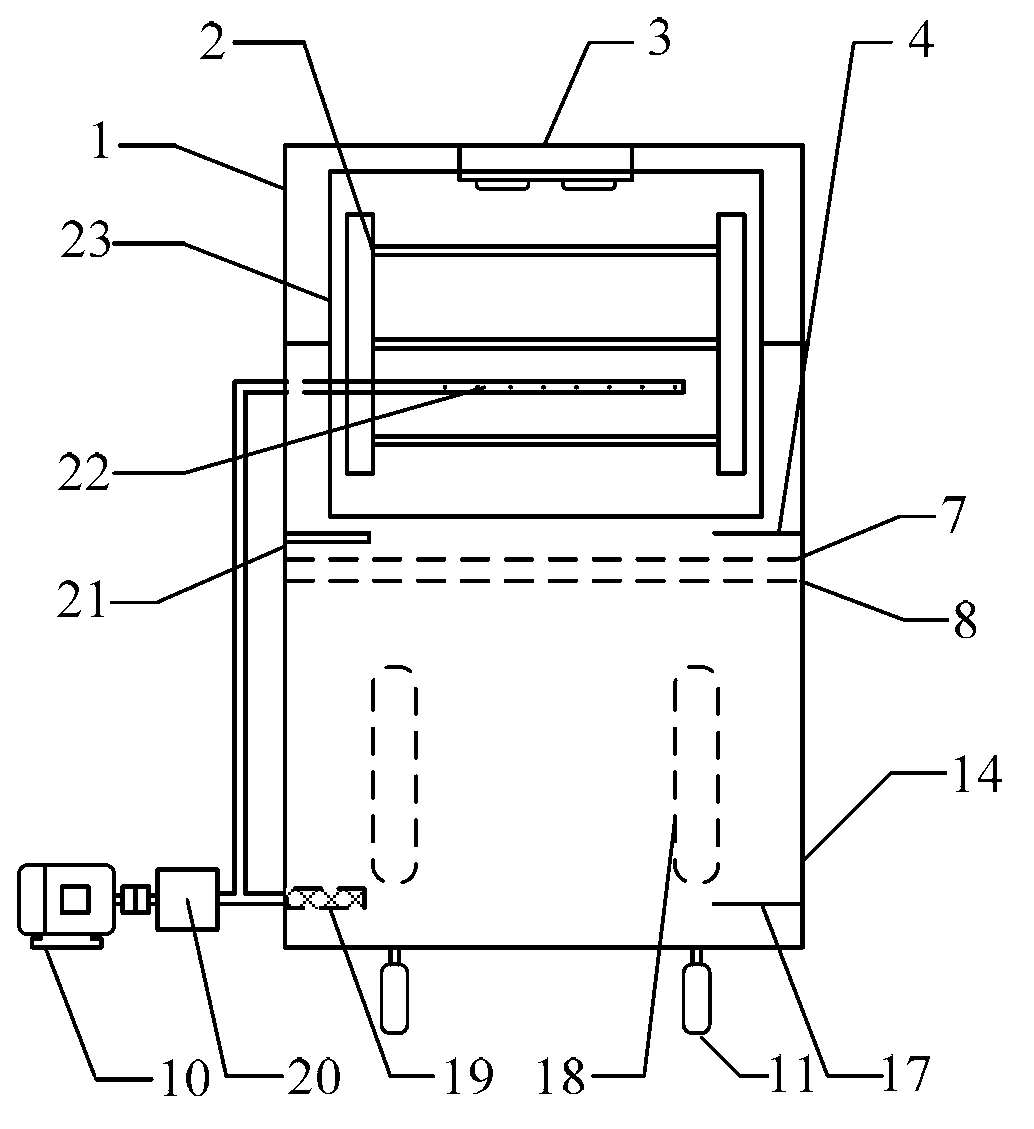

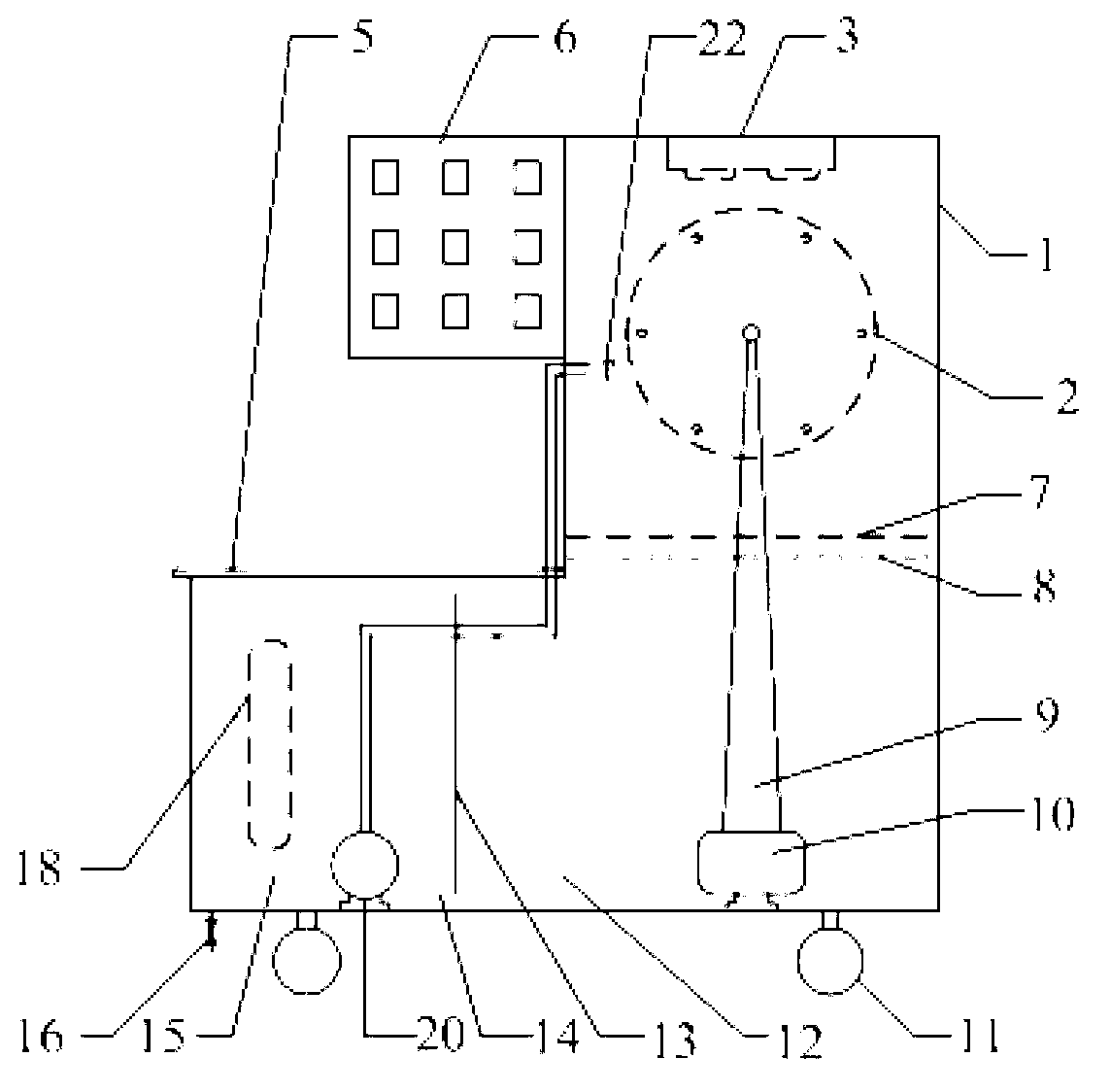

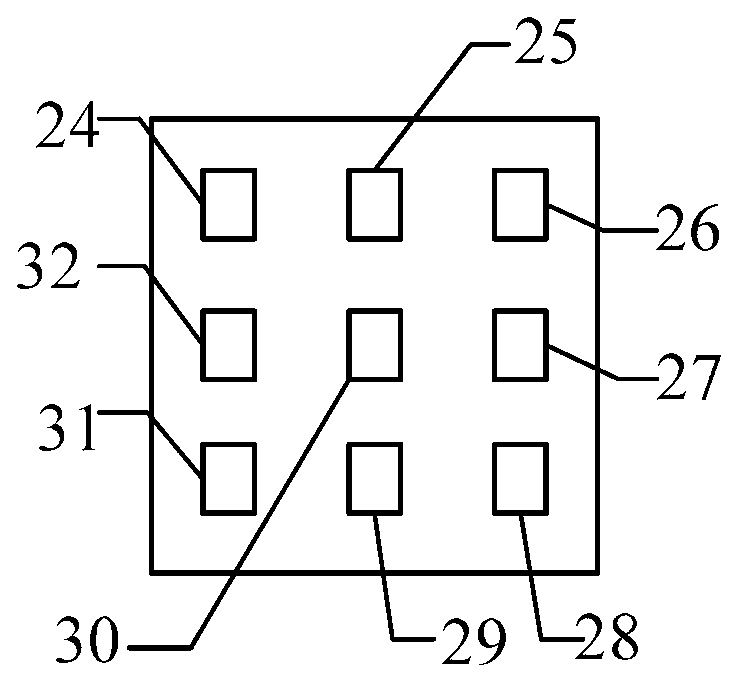

[0036] Such as Figure 1~4 As shown, a corrosion test device for simulating an ocean splash zone includes a box body 1, a liquid storage tank 14, a rotating sample holder 2, a transmission system, a spray system, a lighting system, a temperature control system, a filtration system, a time control system and An automatic control system panel 6, a rotating sample rack 2, a spray system, an illumination system, and a temperature control system are installed in the cabinet 1; a mesh partition 8 is arranged under the rotating sample rack 2 in the cabinet 1, and a filter is placed on the upper part. Net 7; the external transmission system of the casing 1 is connected with the rotating sample rack 2, the bottom of the casing 1 is a liquid storage tank 14, and the overflow plate 13 is arranged in the liquid storage tank 14, and the liquid storage tank is divided into a sedimentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com