Wire with tensile strength>=2000MPa for bridge cable and production method

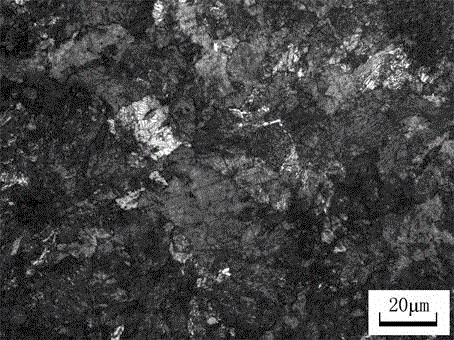

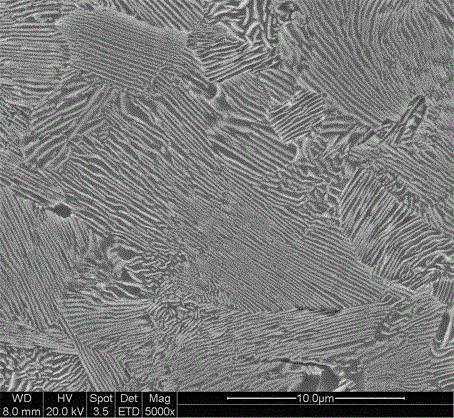

A tensile strength and bridge technology, applied in metal rolling and other directions, can solve the problems of unstable strength and performance, and achieve the effects of uniform metallographic structure and performance, good grain size and grain refinement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below:

[0033] Table 1 is a list of values of various embodiments of the present invention;

[0034] Table 2 is the list of main process parameters of each embodiment of the present invention;

[0035] Table 3 is a list of performance monitoring conditions of various embodiments of the present invention.

[0036] Each embodiment of the present invention is produced according to the following steps:

[0037] Its steps:

[0038] 1) Smelting and continuous casting into slabs, control the cross-sectional size of the slab to at least 300х400mm; control the superheat of the tundish to not exceed 20°C; control the casting speed at 0.3-0.6m / min; control the cross-section of the slab after light reduction The area reduction rate is not more than 8.0%;

[0039] 2) Heating the slab, controlling the soaking temperature at 1250-1500°C, and controlling the time in the furnace for not less than 300 minutes;

[0040] 3) Carry out rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com