Novel artificial marble

An artificial marble, a novel technology, applied in the direction of manufacturing tools, ceramic molding machines, layered products, etc., can solve the problems of marble mechanical performance decline, hinder the application of artificial marble, cracks/cracks, etc., to improve the recycling rate and maintain Mechanical properties, crack/crack prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

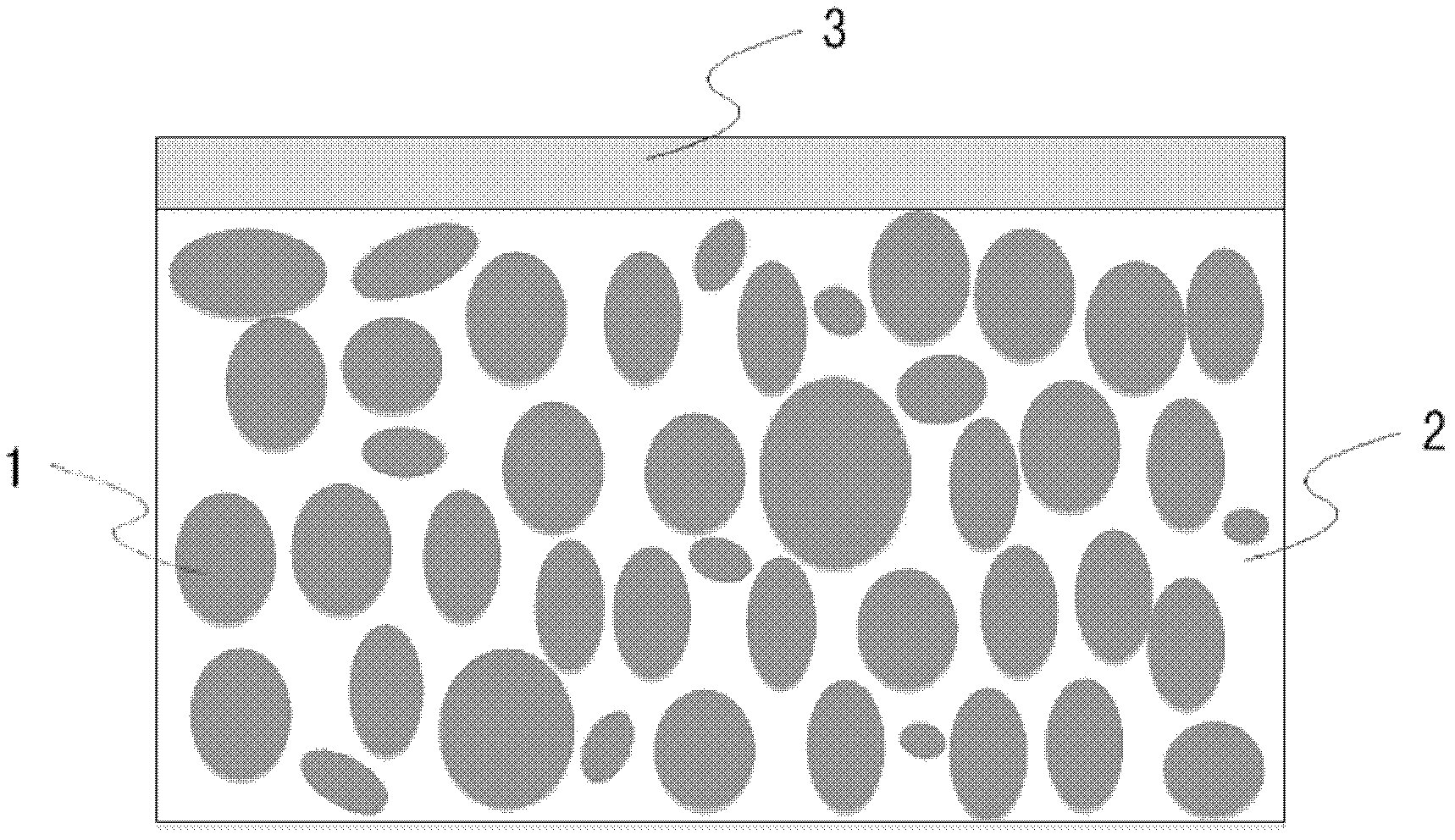

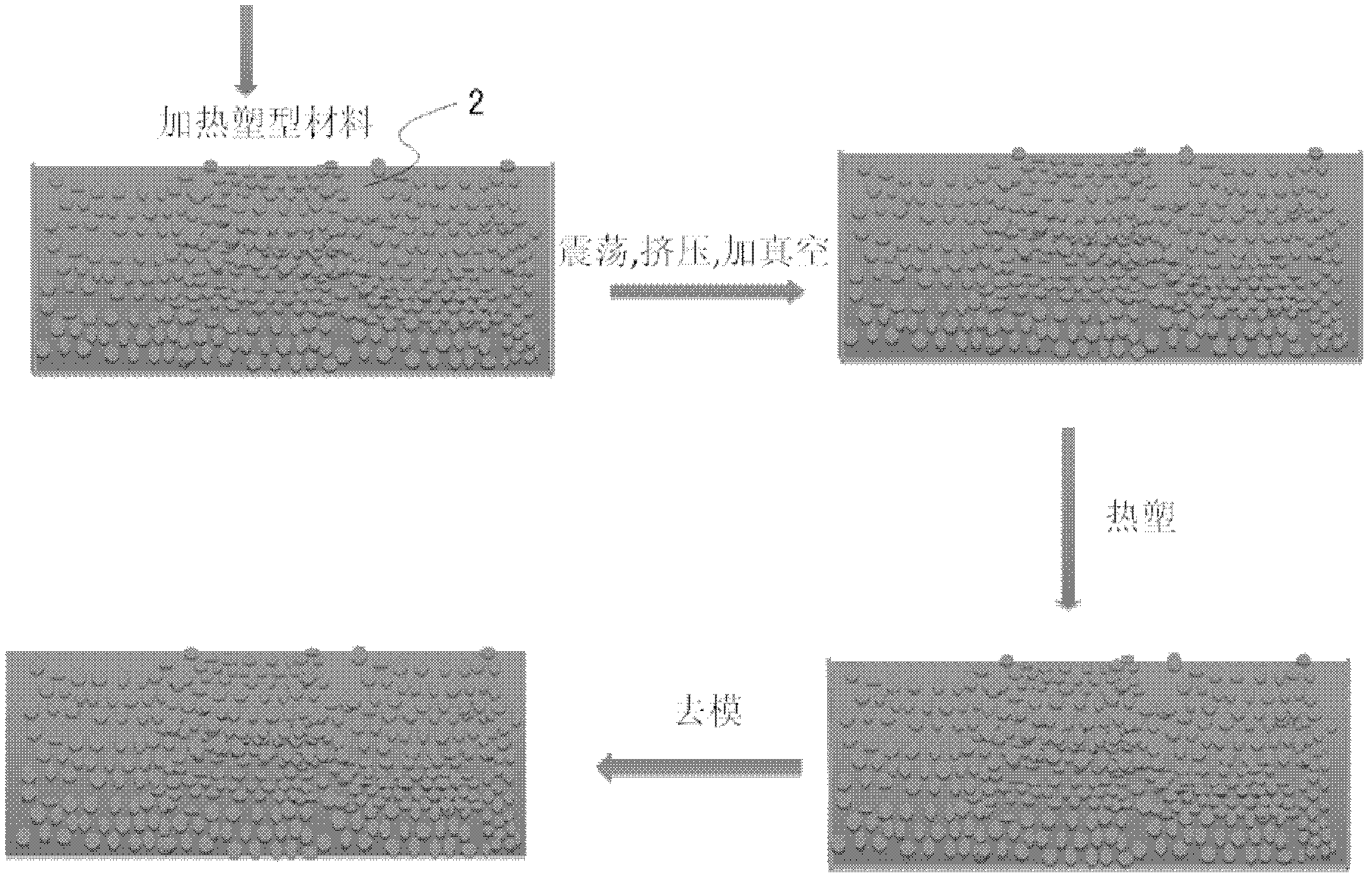

[0066] The structure of the novel artificial marble of the first embodiment of the present invention is as follows figure 1 As shown, it includes a main body layer composed of a filler material 1 and a resin binder material 2, and a coating layer 3 containing titanium dioxide.

[0067] The filling material 1 is an inorganic filling material, and the inorganic filling material is one or more selected from the group consisting of crushed stones, broken bricks, ceramic particles or chips, glass chips, and quartz particles or chips. The granules or powders of the main raw materials of the filling material 1 come from inorganic waste in construction and daily life, and even the waste of artificial marble itself (artificial marble can be recycled after crushing and other treatments). The particle size range of the filler material 1 is usually 0.5-5 mm. The function of the filling material 1 is to form the texture of the artificial marble, to make the appearance beautiful, to increa...

no. 2 approach

[0080] Next, the second embodiment of the present invention will be described, and the description of the structure and technical effect overlapping with the first embodiment will be omitted.

[0081] The structure of the novel artificial marble of the second embodiment of the present invention is as follows Figure 5 As shown, a bulk layer composed of a filler material 1 and a resin binder material 2, and a coating layer 4 containing titanium dioxide are included. The material selection and properties of the filling material 1 and the resin bonding material 2 are the same as those of the first embodiment, and will not be repeated here.

[0082] The second embodiment differs from the first embodiment in that the coating layer 4 includes titanium dioxide.

[0083] The coating layer 4 containing titanium dioxide contains a binder material and the above-mentioned filler material 1 . The adhesive material may be the same as or different from the resin adhesive material 2 describ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com