Method for aligning by combining lenses with multiple magnifications in direct-writing photoetching machine

A direct-write, lithography technology, applied in microlithography exposure equipment, optics, optical components, etc., can solve the problems of difficult to find alignment marks and low alignment accuracy, so as to improve exposure production efficiency and improve accuracy. Quasi-accuracy and the effect of improving the accuracy of the relative positional relationship between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

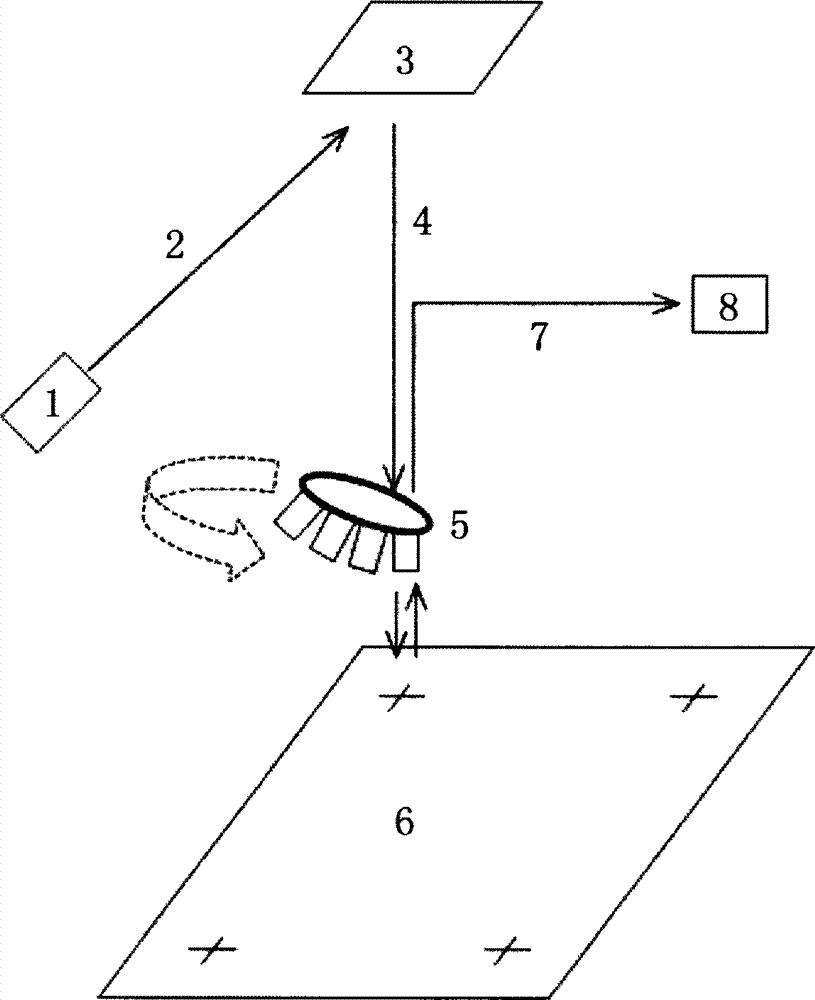

[0023] The purpose of the present invention is to provide a method for aligning multiple magnification lenses in a direct-write photolithography machine to address the shortcomings of the prior art. As one of the more preferred embodiments, the technical solution of the present invention may include:

[0024] (1) First, add a lens converter between the objective lens and the optical path of the direct writing lithography machine;

[0025] (2) Then install the 5x, 10x, 20x and 50x lenses on the lens converter in turn as the alignment lens;

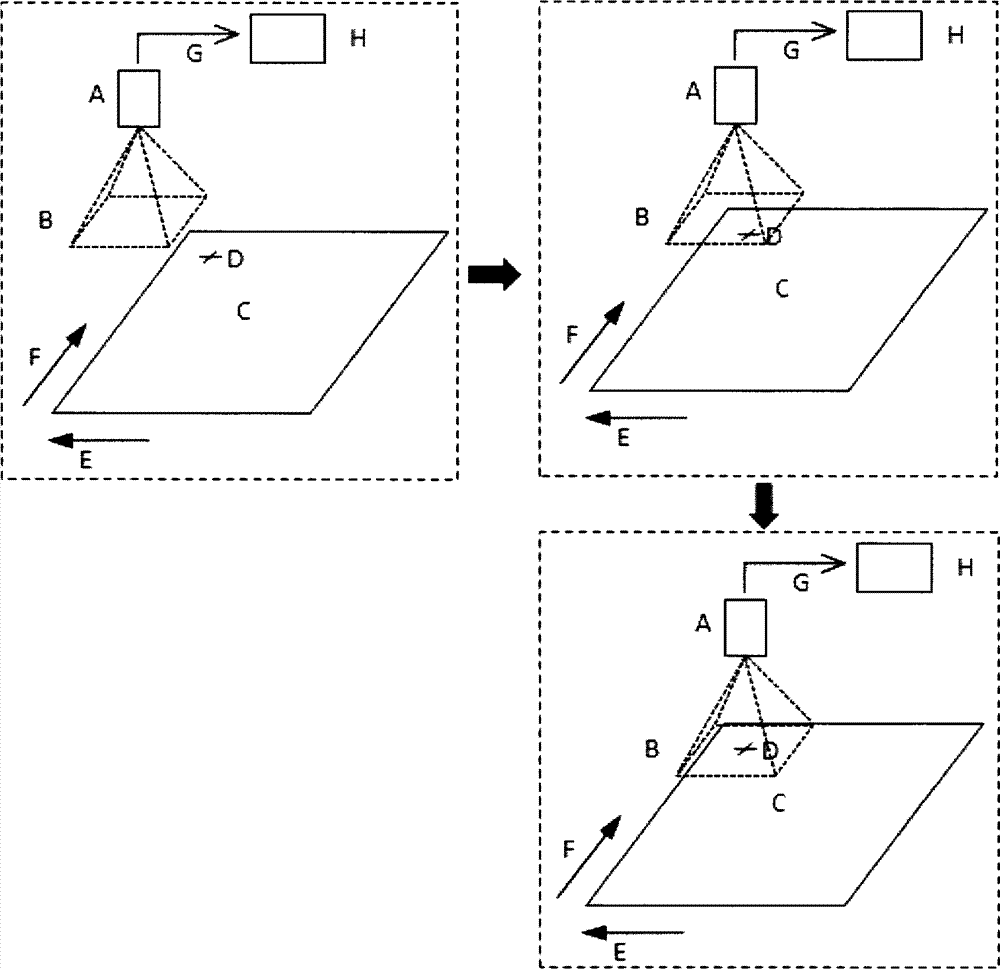

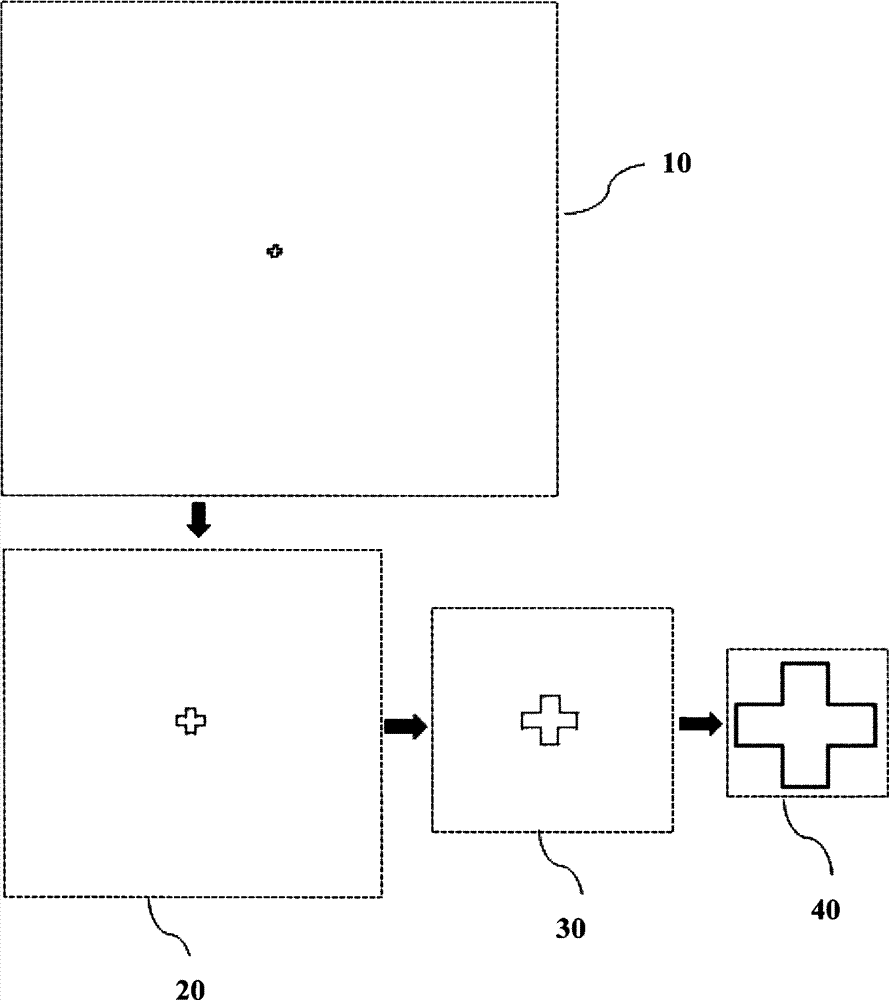

[0026] (3) Use a 5X lens to find the alignment mark, and move the alignment mark to the center of the field of view, then use a 10X lens and a 20X lens to find the alignment mark and move the alignment mark to the center of the field of view;

[0027] (4) Find the alignment mark under the 50X lens and move the alignment mark to the center of the field of view, and then extract the center coordinates of the alignment mark.

[0028] Specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com