Coal gangue thermal insulation raw soil block and preparation method thereof

A technology of coal gangue and raw soil, which is applied in the field of coal gangue thermal insulation raw soil blocks and its preparation, can solve the problems that there are no invention patents for raw soil blocks, etc., achieve enhanced thermal insulation effect, convenient construction, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

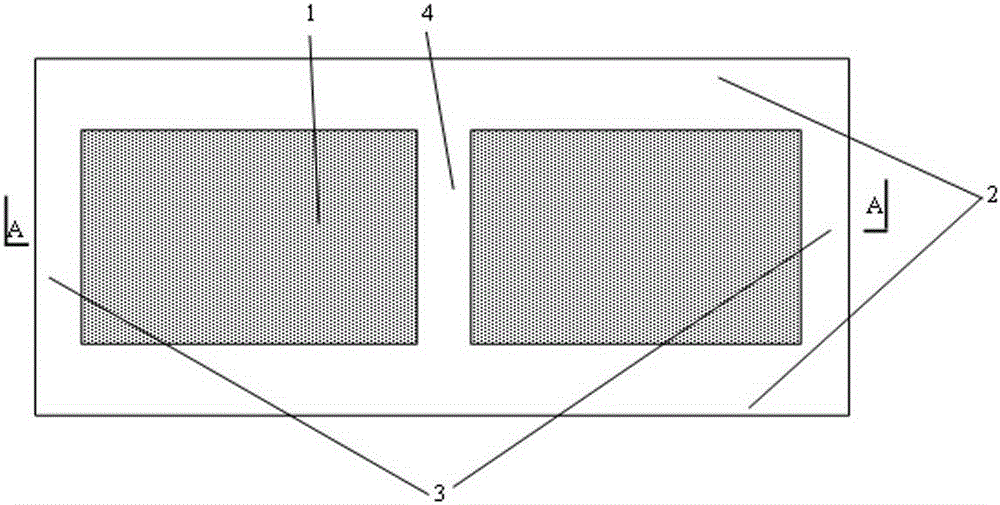

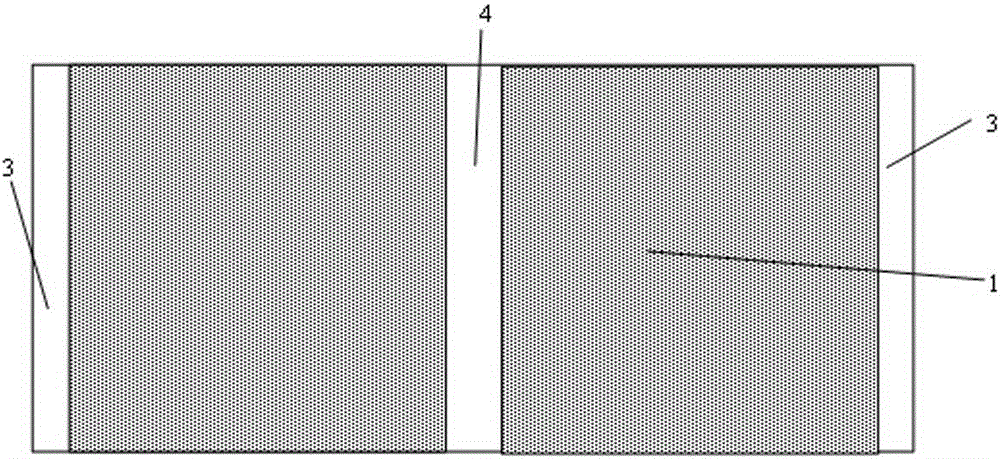

[0026] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

[0027] Such as Figure 1~Figure 2 As shown, the coal gangue thermal insulation raw soil block is composed of thermal insulation layer 1, inner and outer protective layer 2, end protective layer 3 and middle rib 4, the thickness of thermal insulation layer 1 is 140~160mm; the thickness of inner and outer protective layer 2 is 60~70mm ; The thickness of the end protection layer 3 and the middle rib 4 is 50-60mm.

[0028] The thermal insulation layer 1 is composed of the following components: 40-50 parts by weight of agricultural waste, 10-30 parts by weight of clay, 10-30 parts by weight of coal gangue, 4-10 parts by weight of fireproofing agent boric acid , 2-5 parts by weight of antifungal agent borax and 13.2-50 parts by weight of water, the agricultural waste is one or more of rice stalks, corn stalks, sorghum stalks, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com