Flame-retardant coating and preparation method and application thereof

A technology of coating and intumescent flame retardant, which is applied in the field of flame retardant coating and its preparation, can solve the problems of affecting the flame retardant effect, difficulty in obtaining dispersion of nanoparticles and intumescent flame retardant, etc., to achieve improved flame retardant Inflammability, reduction of secondary hazards, and easy operation of the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

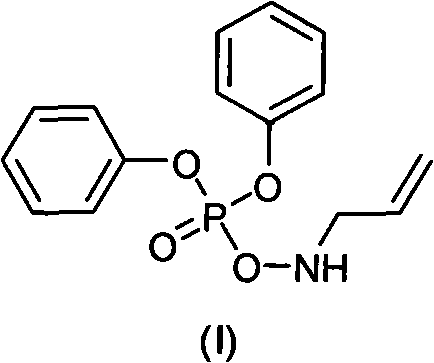

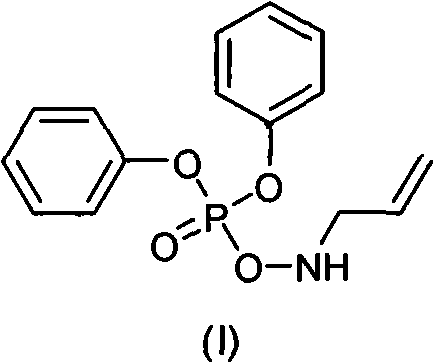

[0033] Example 1: Synthesis of 2-(diphenoxyphosphoryl)propenamine

[0034] Add 26.8g (0.1mol) diphenyl chlorophosphate and 80mL trichloromethane to the there-necked flask, stir the reaction temperature at 25°C, slowly add 5.7g (0.1mol) allylamine and 20.2g (0.2mol) triethylamine dropwise With 54mL of chloroform mixed solution, after adding, maintain 25 ℃ to react for 6 hours, after filtration, the chloroform is recovered by distillation under reduced pressure to obtain a colorless liquid which is 2-(diphenoxyphosphoryl)propenamine, and the yield is 73.2% , with a purity of 96.4%. Structural characterization: FT-IR (cm -1 ): 3375, 1226, 1060, 1009, 956. 1 H NMR (CDCl 3 )δ(ppm): 7.32~7.16(m, 10H), 5.83~5.76(m, 1H), 5.24~5.21(d, 1H), 5.16~5.13(d, 1H), 3.55~3.50(m, 2H) , 3.21(s, 3H).

Embodiment 2

[0036] The synthesis operation of 2-(diphenoxyphosphoryl)propenamine is the same as that in Example 1. The quantity ratio of the feed materials of diphenyl chlorophosphate and allylamine is 1.0: 1.2, dichloromethane is selected as solvent, pyridine is selected as acid binding agent, the reaction temperature is 10 DEG C, the reaction time is 8 hours, and the yield is 60.4%.

Embodiment 3

[0038] The synthesis operation of 2-(diphenoxyphosphoryl)propenamine is the same as that in Example 1. The amount ratio of the feed materials of diphenyl chlorophosphate and allylamine is 1.0: 1.5, ether is selected as solvent, sodium bicarbonate is selected as acid binding agent, reaction temperature is 0 DEG C, and the reaction time is 12 hours, and the yield is 33.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com