Formation method for single-side suture line stitch of three-dimensional composite material prefabricating component

A technology of composite materials and sutures, which is applied in sewing equipment, textiles and papermaking, etc., can solve the problems such as difficult to complete the sewing operation of large structural parts with complex spatial shapes, flexibility limitations, etc., and achieve good sewing effect, flexible operation, and strong Effect of interlaminar fracture toughness and fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with embodiment and accompanying drawing.

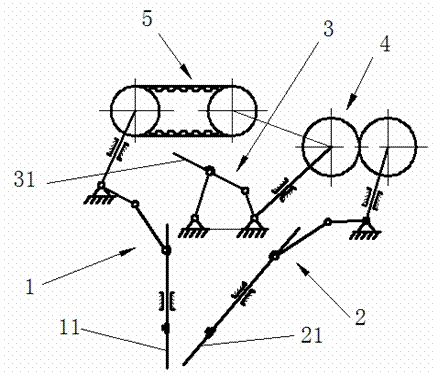

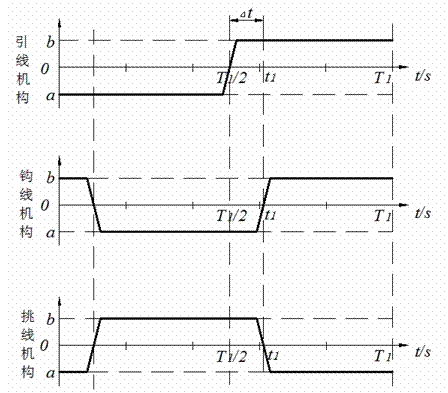

[0025] The forming method (abbreviation forming method or sewing method, see Figure 1-5 ) is based on the "two needles and one thread" suture principle (the "two needles and one thread" principle corresponds to the "one needle and one thread" suture principle of the traditional sewing method, which means that the method requires two needles and one seam Thread to realize sewing operation) design, through the perfect cooperation of the lead thread, hook thread and thread take-up mechanism of the unilateral sewing equipment, the unilateral sewing operation of the three-dimensional composite material prefabricated parts is completed. The crochet needle 11 and thread-leading needle 21 of the forming method of the present invention are all located on the upper surface of the sewing material 6 or the workpiece, and there is no any sewing unit matching the upper surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com