High-room-temperature ductility magnesium alloy material

A magnesium alloy, room temperature technology, which is applied in the field of high room temperature plastic magnesium alloy materials and its preparation, can solve the problems that room temperature formability is not greatly improved, cannot be widely used, and is not suitable for large-scale application, and can improve room temperature ductility. and deformability, low degree of anisotropy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

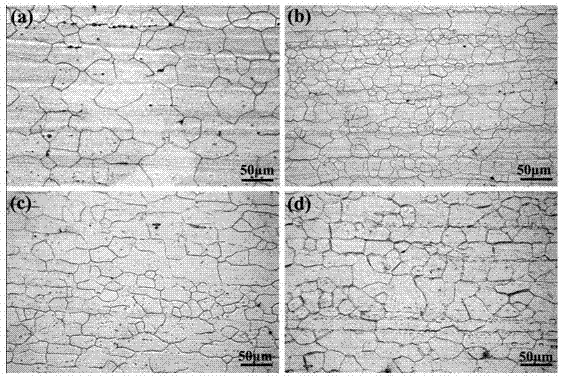

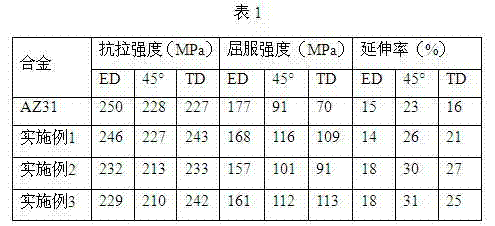

Embodiment 1

[0027] The high room temperature plastic magnesium alloy material of this embodiment consists of the following components by mass percentage:

[0028] Li 1.0%;

[0029] Al 3.0%;

[0030] Zn 1.0%;

[0031] Mn 0.3%;

[0032] Impurities ≤0.3%;

[0033] Magnesium balance.

[0034] The preparation method of the high room temperature plastic magnesium alloy material in this embodiment is to heat the formula amount of pure lithium and AZ31 magnesium alloy to 720°C under the condition of vacuuming and feeding inert gas. Place it for 15 minutes, then pour the smelted alloy liquid into the mold to obtain the as-cast magnesium alloy; heat the as-cast magnesium alloy at 380°C for 3 hours and extrude it into a magnesium alloy plate with a thickness of 2mm and a width of 120mm (extrusion machine Tonnage 1250T, extrusion cylinder diameter 165mm, extrusion ratio: 89).

Embodiment 2

[0036] The high room temperature plastic magnesium alloy material of this embodiment consists of the following components by mass percentage:

[0037] Li 3.0%;

[0038] Al 3.0%;

[0039] Zn 1.0%;

[0040] Mn 0.3%;

[0041] Impurities ≤0.3%;

[0042] Magnesium balance.

[0043] The preparation method of the high room temperature plastic magnesium alloy material in this embodiment is to heat the formula amount of pure lithium and AZ31 magnesium alloy to 720°C under the condition of vacuuming and feeding inert gas. Place it for 15 minutes, then pour the smelted alloy liquid into the mold to obtain the as-cast magnesium alloy; heat the as-cast magnesium alloy at 380°C for 3 hours and extrude it into a magnesium alloy plate with a thickness of 2mm and a width of 120mm (extrusion machine Tonnage 1250T, extrusion cylinder diameter 165mm, extrusion ratio: 89).

Embodiment 3

[0045] The high room temperature plastic magnesium alloy material of this embodiment consists of the following components by mass percentage:

[0046] Li 5.0%;

[0047] Al 3.0%;

[0048] Zn 1.0%;

[0049] Mn 0.3%;

[0050] Impurities ≤0.3%;

[0051] Magnesium balance.

[0052] The preparation method of the high room temperature plastic magnesium alloy material in this embodiment is to heat the formula amount of pure lithium and AZ31 magnesium alloy to 720°C under the condition of vacuuming and feeding inert gas. Place it for 15 minutes, then pour the smelted alloy liquid into the mold to obtain the as-cast magnesium alloy; heat the as-cast magnesium alloy at 380°C for 3 hours and extrude it into a magnesium alloy plate with a thickness of 2mm and a width of 120mm (extrusion machine Tonnage 1250T, extrusion cylinder diameter 165mm, extrusion ratio: 89).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com