Trichoderma atroviride strain and application thereof in preparation of cellulase

A technology of Trichoderma viridans and cellulase, applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., to achieve the effects of high activity, short fermentation cycle, and reasonable components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Trichoderma dark green B-8-1-34 liquid fermentation enzyme production

[0025] After the activation of the Trichoderma dark green B-8-1-34 bacterial strain whose strain preservation number is CGMCC No. 6390, 10 6 mL of spore suspension, inoculate 5% of the inoculum into the seed medium, culture at 30°C, 180rpm shaker for 24 hours, then inoculate the liquid enzyme production medium with 10% inoculum (filling volume 40 mL / 250mL), with an initial pH of 4.0-6.0, cultured at 30°C, 200rpm shaker to 66, and centrifuged at 4000r / min for 10min to prepare crude enzyme solution.

[0026] The composition of the seed medium: carboxymethyl cellulose 1%, peptone 0.2%, (NH 4 ) 2 SO 4 0.3%, MgSO 4 0.04%, CaCl 2 0.04%, KH 2 PO 4 0.1%, the balance is distilled water. Each component is expressed in weight percent.

[0027] The composition of the liquid fermentation medium: 2.5% of corn stalks, corn cobs, wheat straw or xylose residue and 0.5% of rice straw, and adde...

Embodiment 2

[0032] Embodiment 2 Trichoderma dark green B-8-1-34 solid state fermentation produces enzyme

[0033] The concentration made by activating the Trichoderma dark green strain with the strain preservation number of CGMCC No. 6390 is 10 8 The spore suspension per ml was inserted into the seed medium, cultivated in a shaker at 30°C and 180rpm for 24h, and then connected to the solid fermentation medium with 3% inoculum for cultivation, and the material was turned over regularly. 10 times the volume of 0.05 mol / L citric acid-sodium citrate buffer solution with pH 5.0, shaking and extracting at 150 rpm, and centrifuging at 4000 r / min for 10 min to prepare the crude enzyme solution.

[0034] The composition of the seed medium: carboxymethyl cellulose 1%, peptone 0.2%, (NH 4 ) 2 SO 4 0.3%, MgSO 4 0.04%, CaCl 2 0.04%, KH 2 PO 4 0.1%, the balance is distilled water. Each component is expressed in weight percent.

[0035] The composition of the solid fermentation medium: co...

Embodiment 3

[0040] Example 3 Application of saccharified lignocellulose

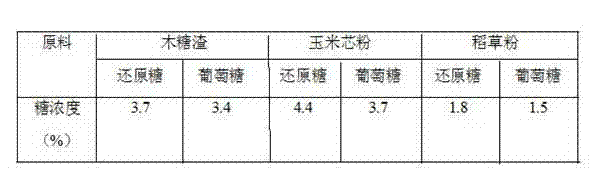

[0041] In 0.05mol / L acetic acid-sodium acetate or citric acid-sodium citrate buffer solution with pH 5.0, add the crude enzyme liquid or enzyme powder prepared above to corncobs, rice straw powder or xylose residue, and the ratio of solid to liquid is 1:10, 50°C, 180rpm hydrolysis for 48 hours, then measure reducing sugar concentration and glucose concentration, the results are shown in Table 3. . The amount of enzyme added is 4FPA / ml. Lignocellulose and enzymes can be added all at once or in batches.

[0042] Table 3 Results of saccharified lignocellulose

[0043]

[0044] Note: The DNS method is used for the determination of reducing sugar; the enzyme method is used for the determination of glucose (SBA-40c biosensor analyzer)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com