High-temperature resistant steam chemical auxiliary agent for thermal oil recovery

A technology of steam chemical and thermal oil recovery, which is applied in chemical instruments and methods, production fluids, earth drilling and production, etc., to achieve the effects of high activity, enhanced oil recovery, and enhanced oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

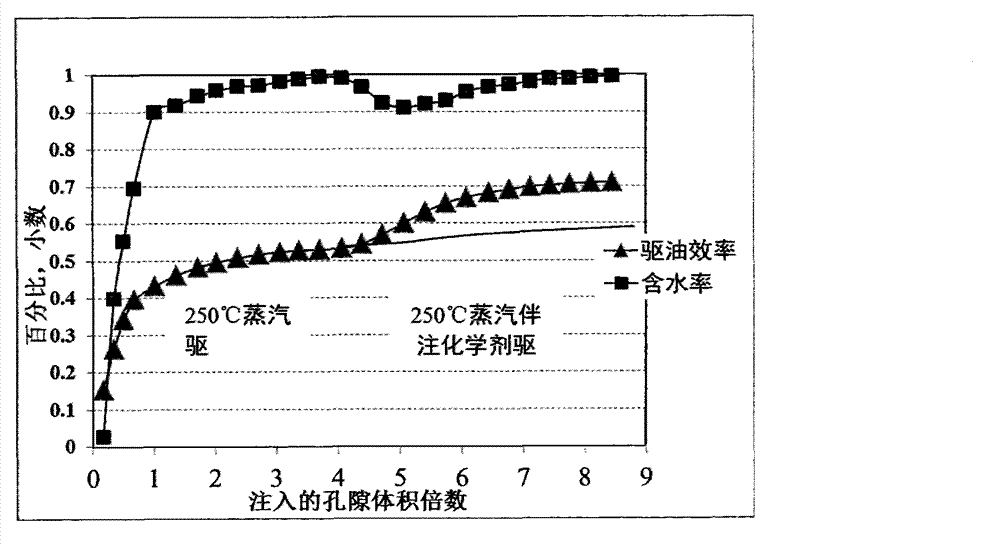

[0024] Formulate 75% poly fatty acid amidopropyl dimethyl tertiary amine + 25% isobutanol into an auxiliary thermal oil displacement steam chemical additive, and configure this auxiliary thermal oil displacement steam chemical additive into a 0.1% microemulsion agent, According to the enterprise standard Q / SH 10201258-2005 of Shengli Petroleum Administration Bureau of Sinopec Group, the simulated steam flooding experiment was carried out. The steam temperature was 250°C, and the size of the sand filling model was Φ50×1000mm. The Shengli heavy oil used in the experiment was dehydrated and degassed at 50°C. The viscosity is 17314mpa.s, and the model permeability is 2.35dc. During the experiment, use a high-pressure metering pump to inject water into the damper system at a flow rate of 5mL / min, start the steam generation system, and make the steam at the outlet of the steam generator reach the following indicators: temperature 250°C, dryness 20%, pressure 4.1Mpa. The electric val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com