Combined treatment method of oil-refining wastewater containing naphthenic acid

A treatment method and technology for oil refining sewage, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., which can solve the problems of frequent replacement, unremoved pollutants, and high operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

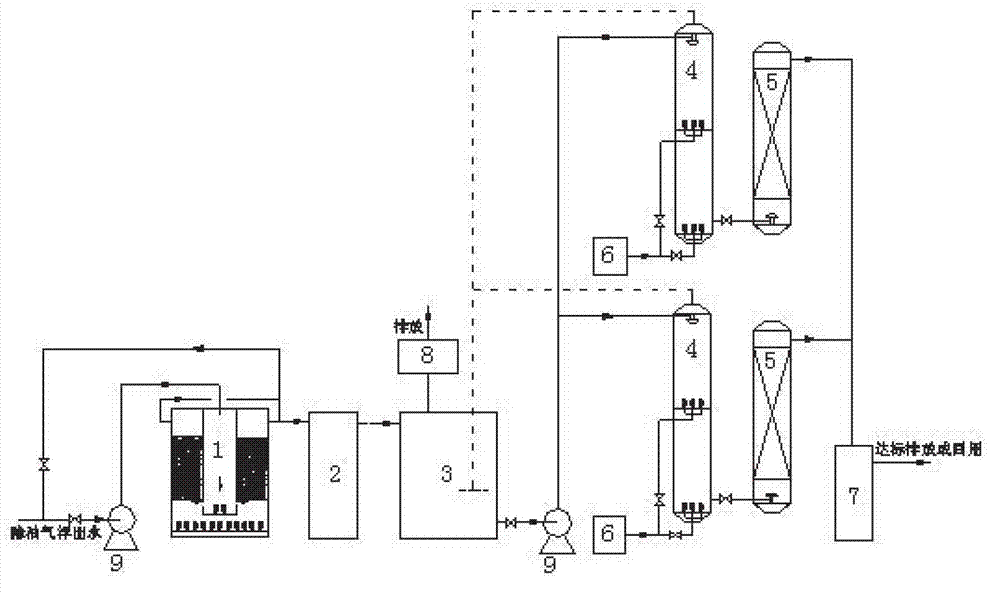

Method used

Image

Examples

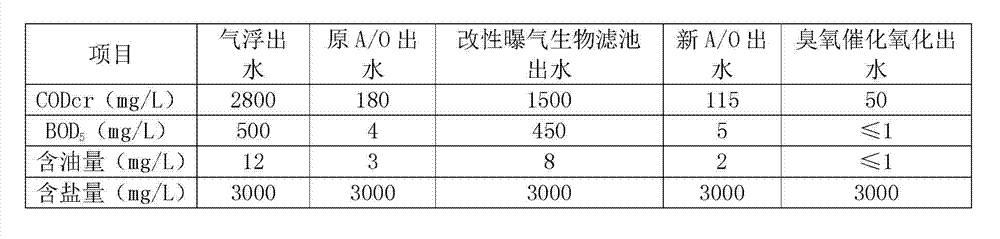

Embodiment 1

[0016] According to the above process, a certain oil refinery is used for sewage treatment, and the reaction conditions are as follows: the modified biological aerated filter adopts upstream continuous operation, the filler is selected volcanic rock modified by sulfuric acid, and the hydraulic load is 2.0m 3 / m 2 h, the average temperature is 30°C, the reflux ratio is 120%, the air-water ratio is 4:1, and the automatic backwash cycle is 48h. Modified alumina is selected as the carrier of the catalyst, loaded with active metal oxides of 3.0% copper and 2.0% manganese, the reaction time of the single-stage premixed tower is 30min, the dosage of single-stage ozone is 30mg / L, and the single-stage catalytic The oxidation tower reaction time is 20min, and the results are shown in Table 1:

[0017] Table 1 Treated effluent water quality

[0018]

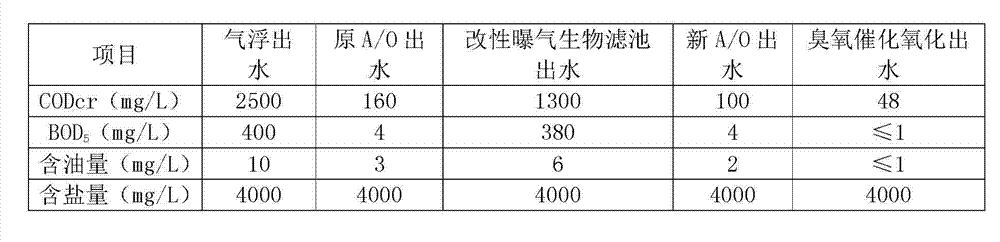

Embodiment 2

[0020] According to the above process, a certain oil refinery is used for sewage treatment, and the reaction conditions are as follows: the modified biological aerated filter adopts upstream continuous operation, the filler is selected from fly ash modified by sulfuric acid, and the hydraulic load is 3.0m 3 / m 2 h, the average temperature is 25°C, the reflux ratio is 100%, the air-water ratio is 3:1, and the automatic backwash cycle is 72h. Granular activated carbon is used as the catalyst carrier, loaded with active metal oxides of 4.0% iron and 2.5% nickel, the reaction time of the single-stage premixed tower is 45min, the dosage of single-stage ozone is 25mg / L, and the single-stage catalytic oxidation tower The reaction time is 15min, and the results are shown in Table 2:

[0021] Table 2 Treated effluent water quality

[0022]

Embodiment 3

[0024] According to the above process, a certain oil refinery is used for sewage treatment, and the reaction conditions are as follows: the modified biological aerated filter adopts upstream continuous operation, the filler is zeolite modified by hydrochloric acid, and the hydraulic load is 1.0m 3 / m 2 h, the average temperature is 35°C, the reflux ratio is 150%, the air-water ratio is 5:1, and the automatic backwash cycle is 60h. Fly ash is used as the carrier of the catalyst, loaded with active metal oxides of 2.0% copper, 3.0% iron and 5.0% manganese, the reaction time of the single-stage premixed tower is 60min, and the dosage of single-stage ozone is 35mg / L. The reaction time of the single-stage catalytic oxidation tower is 20 minutes, and the results are shown in Table 3:

[0025] Table 3 Treated effluent water quality

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com