Gantry clutch friction steel disc repairing device and reproducing method thereof

A gantry-type, clutch technology, applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of insufficient contact between the friction steel plate and the friction plate, poor control of grinding strength and time, and increase the cost of the car owner Burden and other issues, to achieve good social benefits, improve the success rate of loading, the effect of small grinding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, principle and technical solution of the present invention clearer, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments. The products and methods involved are clear and achievable to those skilled in the art.

[0020] The purpose of the present invention is to develop a device that can replace manual grinding of clutch friction plates. The device must possess stability and accuracy that cannot be achieved by manual grinding.

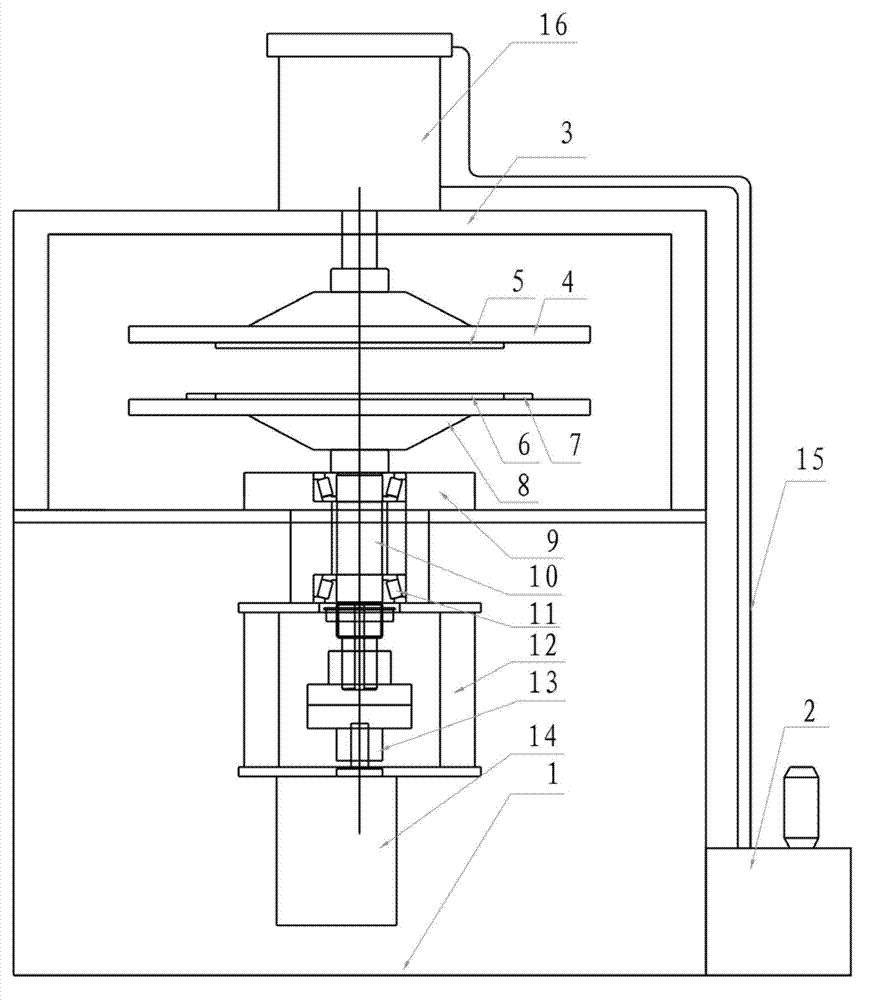

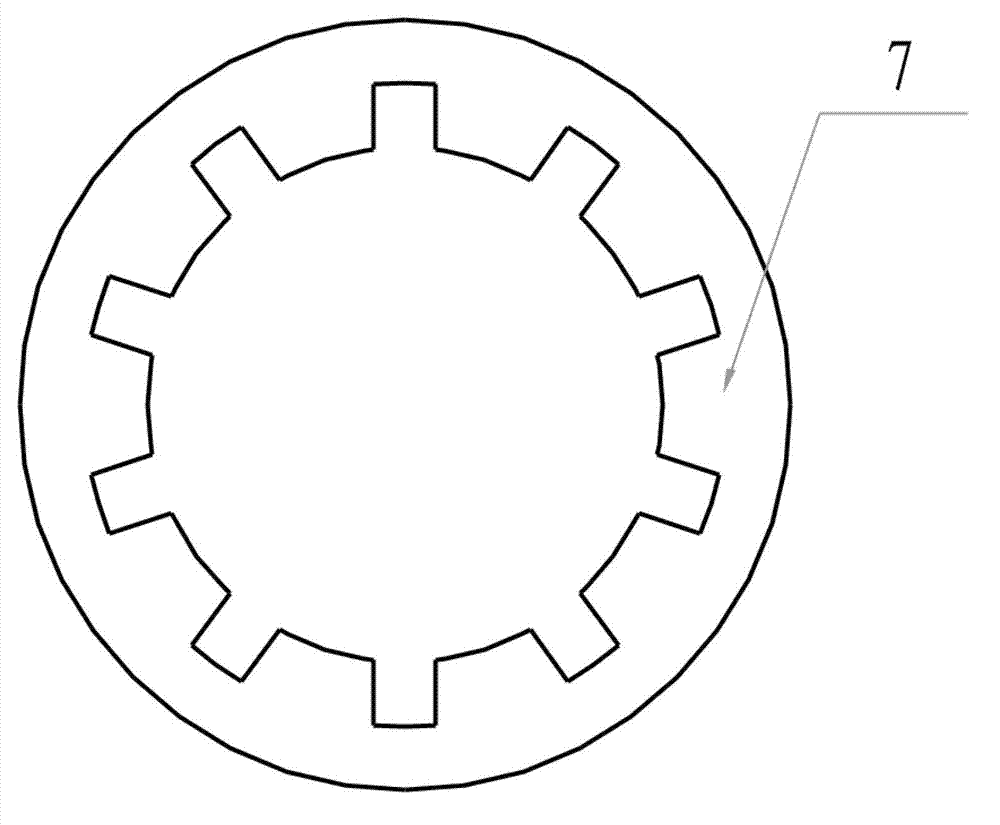

[0021] Such as figure 1 As shown, the gantry clutch friction steel repair equipment includes a base 1, a hydraulic station 2, a gantry frame 3, a grinding wheel disc 4, a grinding wheel 5, a friction steel plate 6, a friction steel clamp 7, a friction steel support plate 8, and a shaft sleeve 9. Main shaft 10, tapered roller bearing 11, fixed frame 12, coupling 13, micro speed-regulating motor 14, oil pipe 15, hydraulic cylinder 16, among which:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com