Washing descaling ball with mesh surface

A mesh and surface technology, applied in the field of cleaning and descaling balls, can solve problems such as complicated operation of the rubber ball cleaning system, increased energy consumption, and shortened service life of equipment, and achieve excellent cleaning and descaling effects, ball collection rate and operation The effect of high cycle rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

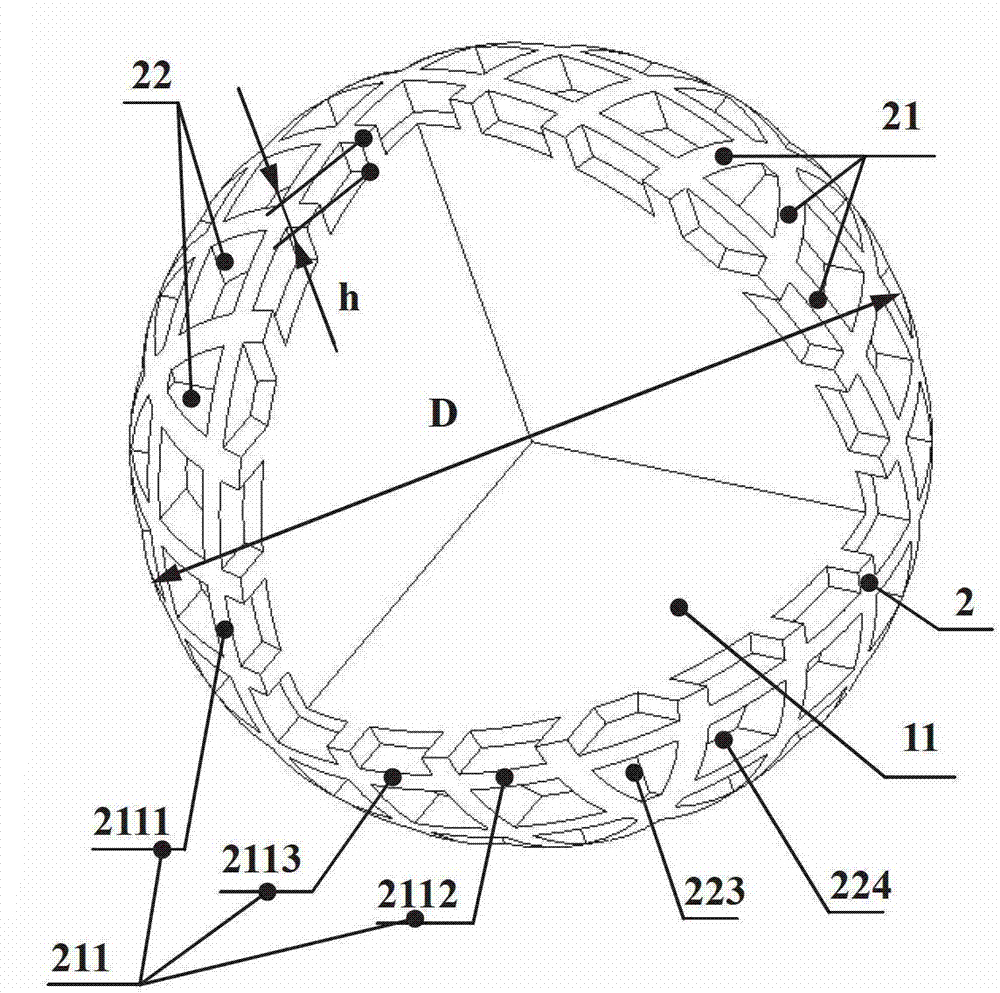

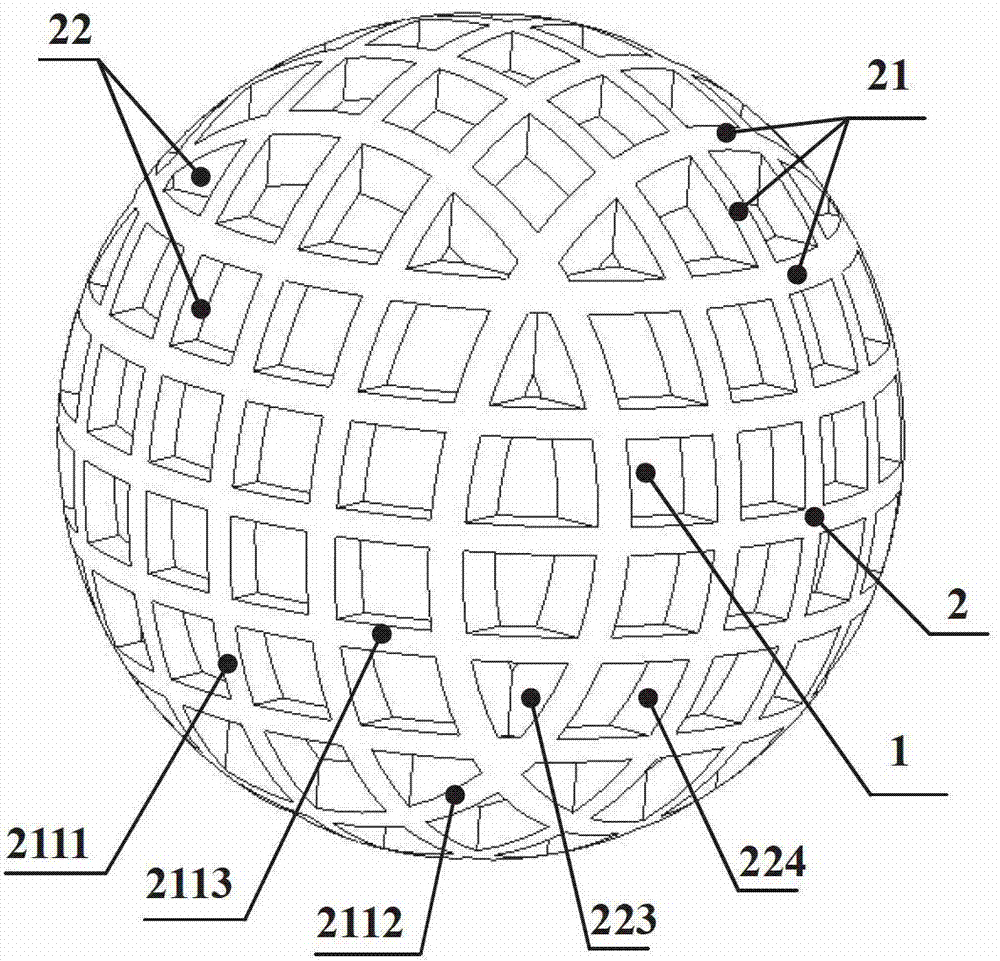

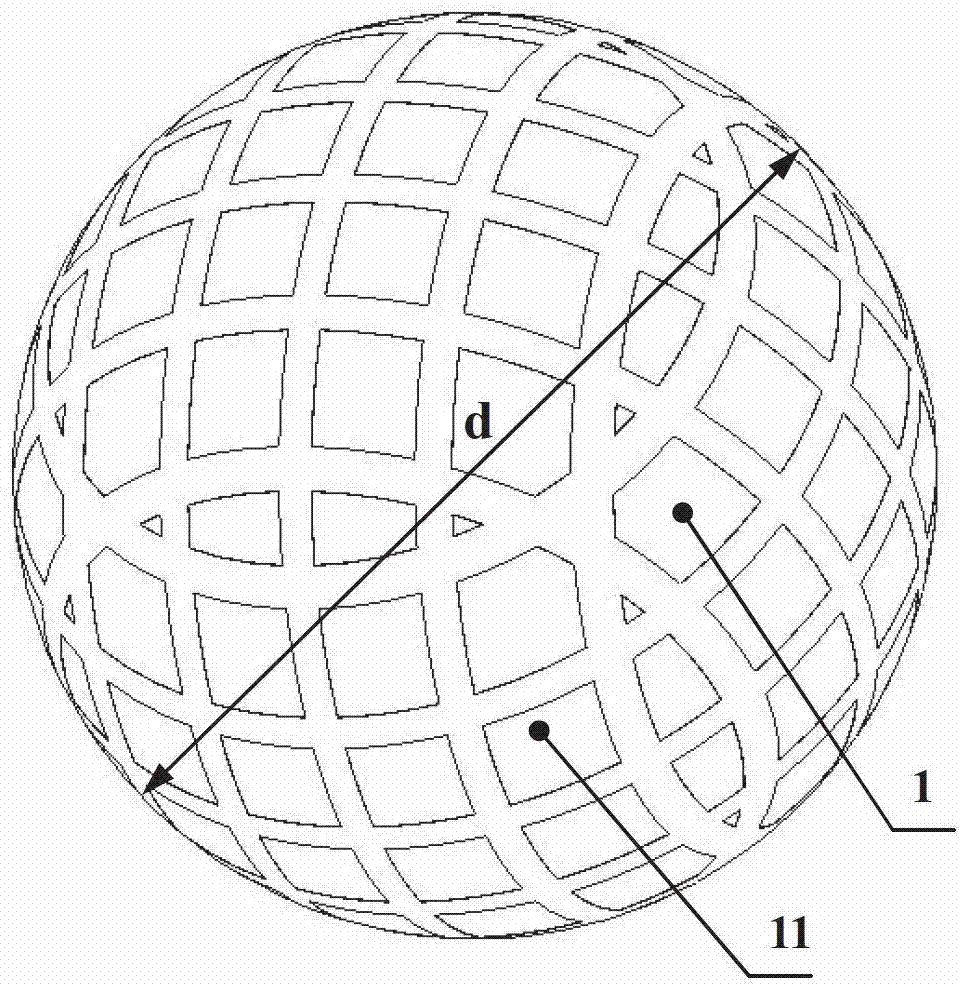

[0041] figure 1 It is a schematic diagram of a three-dimensional structure of a cleaning and descaling ball with a mesh surface layer in Example 1 of the present invention, figure 2 It is a schematic diagram of a three-dimensional partial cross-sectional structure of a cleaning and descaling ball with a mesh surface layer according to Embodiment 1 of the present invention, image 3 It is a schematic diagram of the three-dimensional structure of the inner ball of Example 1 of the present invention, Figure 4 It is a schematic diagram of the three-dimensional structure of the mesh surface layer of Example 1 of the present invention.

[0042] exist Figure 1-4Among them, a cleaning and descaling ball with a mesh surface layer includes an inner ball 1 and a mesh surface layer 2 located outside the inner ball 1 and connected with the inner ball 1 as a whole. In this embodiment, the inner ball 1 is a solid sphere, and the mesh surface layer 2 is a spherical shell with holes insi...

example 1

[0055] Figure 7 It is a schematic diagram of a three-dimensional structure of a cleaning and descaling ball with a mesh surface layer in Modification 1 of Embodiment 1 of the present invention, Figure 8 It is a schematic diagram of a three-dimensional partial cross-sectional structure of a cleaning and descaling ball with a mesh surface layer in Modification 1 of Embodiment 1 of the present invention.

[0056] exist Figure 7 and Figure 8 Among them, a cleaning and descaling ball with a mesh surface layer includes an inner ball 1 and a mesh surface layer 2 located outside the inner ball 1 and connected with the inner ball 1 as a whole. In Modification 1 of Embodiment 1, the inner ball 1 is a perforated sphere 12 , and the perforated sphere 12 has an inner ball hole 121 opened therein. The mesh surface layer 2 is a spherical shell with holes inside and outside. The outside of the inner ball 1 is connected to the inside of the mesh surface layer 2 as a whole, and the outer...

Deformed example 2

[0060] Figure 9 It is a schematic diagram of a three-dimensional partial cross-sectional structure of a cleaning and descaling ball with a mesh surface layer according to Modification 2 of Embodiment 1 of the present invention. exist Figure 7 Among them, a cleaning and descaling ball with a mesh surface layer includes an inner ball 1 and a mesh surface layer 2 located outside the inner ball 1 and connected with the inner ball 1 as a whole. The inner ball 1 is an inner composite ball 13, and the inner composite ball 13 includes an inner composite ball outer layer 131, an inner composite ball middle layer 132 and an inner composite ball inner layer 133, wherein the material of the inner composite ball outer layer 131 is the same as that of the inner composite ball outer layer 131. The mesh surface layer 2 is the same, and the inner composite ball middle layer 132 and the inner composite ball inner layer 133 can adopt different materials, such as the inner composite ball middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com