One-piece high-power LED integrated light source with more than two convex mirrors and its manufacturing process

A high-power, integrated technology, which is applied in the field of integrated high-power LED integrated light source and manufacturing process, can solve the problems of poor concentrating effect of LED integrated light source, quality influence of LED integrated light source, and difficulty in controlling the authenticity rate, etc. Easy to mold, good coincidence, and good consistency of light and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

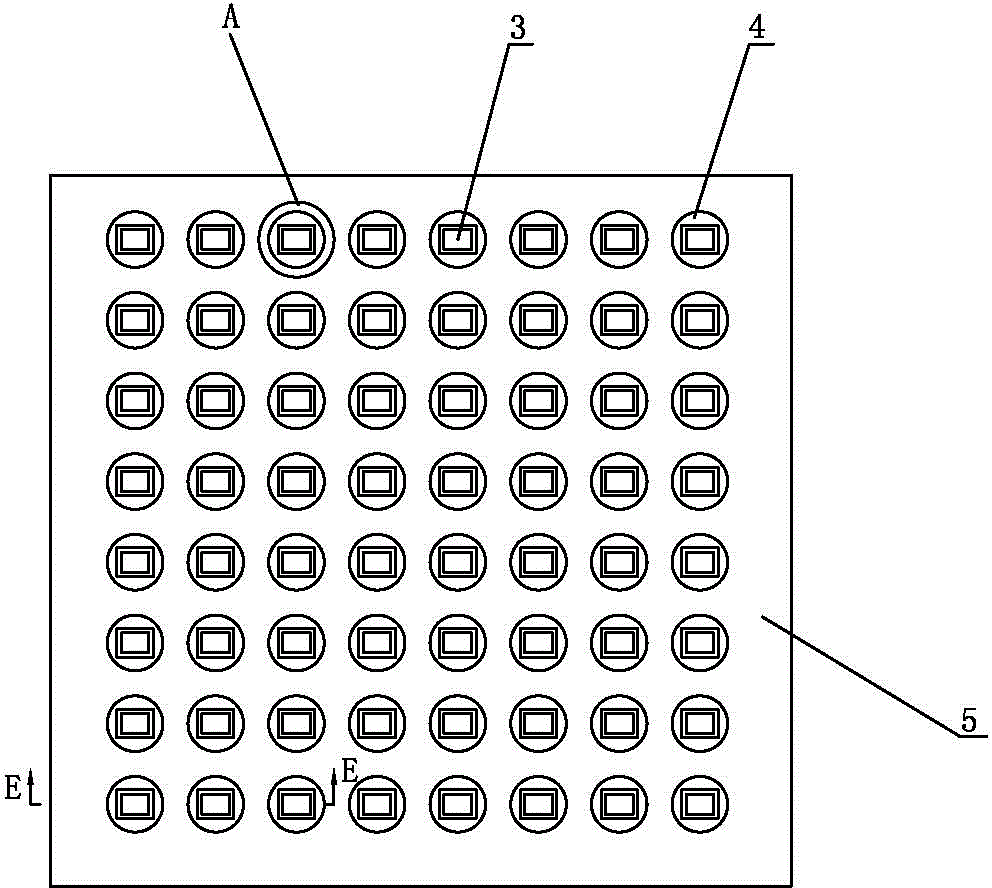

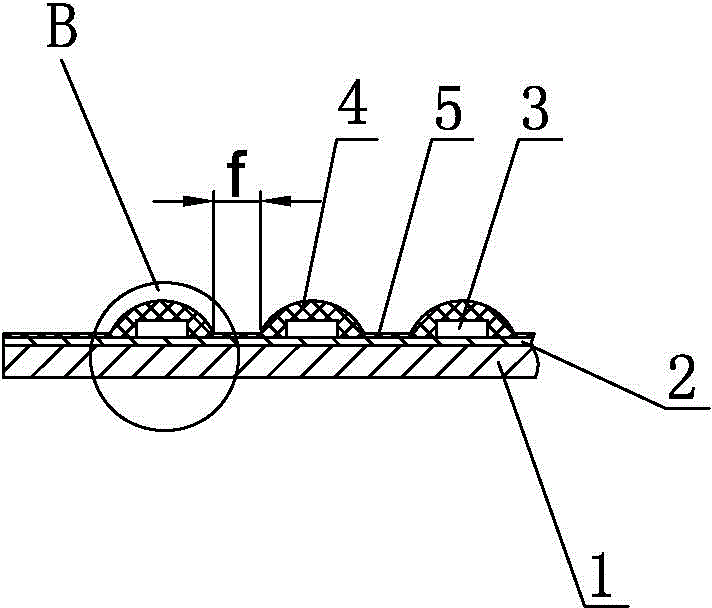

[0042] Such as Figure 1 to Figure 4 As shown, the integrated high-power LED integrated light source with more than two convex mirrors includes a substrate 1, a circuit layer 2, more than two LED chips 3, a convex mirror 4, and a film 5. The substrate 1 is a ceramic substrate, and the circuit layer 2 is arranged on the ceramic substrate. By setting the substrate as a ceramic substrate, thermoelectric separation can be realized, and the thermal conductivity of the ceramic substrate is high, the heat dissipation effect is good, and the internal stress of the package is also small. The LED chip 3 is arranged on the substrate 1, and is electrically connected to the circuit layer through a gold wire. Of course, the LED chip flip-chip eutectic technology can also be used to realize the electrical connection between the LED chip and the circuit layer; the LED chip 3 is sprayed with phosphor powder, and the convex mirror 4 described above is quantitatively pressed and formed on each L...

no. 2 approach

[0061] Such as Figure 5 to Figure 8 As shown, the integrated high-power LED integrated light source with more than two convex mirrors includes a substrate 1, a circuit layer 2, more than two LED chip modules, a convex mirror 4, and a film 5. The substrate 1 is a ceramic substrate, and the circuit layer 2 is arranged on the ceramic substrate. By setting the substrate as a ceramic substrate, thermoelectric separation can be realized, and the thermal conductivity of the ceramic substrate is high, the heat dissipation effect is good, and the internal stress of the package is also small. The LED chip module is composed of more than two LED chips 3, and is arranged on the substrate 1. The LED chips 3 are electrically connected to the circuit layer through gold wires. Of course, the LED chips can also be flip-chip shared Crystallization technology realizes the electrical connection between the LED chip and the circuit layer; the LED chip module is sprayed with phosphor powder, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com