Preparation method of nano manganese oxide

An oxide and nanomanganese technology, applied in nanotechnology, manganese oxide/manganese hydroxide and other directions, can solve the problems of complex process equipment, high energy consumption, and high reaction temperature, and achieve common and easy availability of raw materials, low energy consumption, and high production efficiency. The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh manganese acetate (Mn(CH 3 COO) 2 4H 2 O, AR, molecular weight (245.10), 24.5 g (0.1 mol), dissolved in 62 g of deionized water to form a 20% manganese acetate solution, heated to 40°C in a water bath, to which 8.81 g of ascorbic acid granules were added (0.05 mol), stirred to dissolve in manganese acetate solution, denoted as A1.

[0023] Raise the temperature of the water bath to 50° C., and place A1 there for 8 hours to form B1.

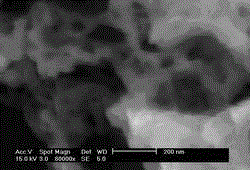

[0024] Put B1 into an oven, bake at 110°C for 4 hours, put it into a muffle furnace, and bake at 320°C for 4 hours to form C1. C1 was analyzed and tested by SEM, and the results of crystal form and particle size are shown in Table 1.

Embodiment 2

[0026] Weigh manganese acetate (Mn(CH 3 COO) 2 4H 2 O, AR) 24.5 g (0.1 mol), which was dissolved in 62 g of deionized water to form a 20% manganese acetate solution, heated to 40°C in a water bath, to which 52.8 g of ascorbic acid particles (0.3 mol) were added, Stir to dissolve it in the manganese acetate solution, denoted as A2.

[0027] Raise the temperature of the water bath to 60°C, and place A2 there for 8 hours to form B2.

[0028] Put B2 into an oven, bake at 110°C for 4 hours, put it into a muffle furnace, and bake at 350°C for 2 hours to form C2. C2 was analyzed and tested by SEM, and the results of crystal form and particle size are shown in Table 1.

Embodiment 3

[0030] Weigh manganese acetate (Mn(CH 3 COO) 2 4H 2 O, AR) 24.5 g (0.1 mol) was dissolved in 62 g of deionized water to form a 20% manganese acetate solution, and after heating to 40 °C in a water bath, 35.2 g of ascorbic acid particles (0.2 mol) were added to it, Stir to dissolve it in the manganese acetate solution, denoted as A3.

[0031] Raise the temperature of the water bath to 50° C., and place A3 there for 8 hours to form B3.

[0032] Put B3 into an oven, bake at 110°C for 4 hours, put it into a muffle furnace, and bake at 450°C for 4 hours to form C3. The C3 was analyzed and tested by SEM, and the results of crystal form and particle size are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com