Method and equipment for intermittently recycling waste liquid of chlorosilane during polycrystalline silicon production

A technology of polysilicon and chlorosilane, which is applied in the direction of halosilane and halide silicon compounds, can solve the problems of environmental pollution, large amount of human labor, high cost, etc., and achieve the advantages of easy realization of process conditions, reduction of human labor, and improvement of processing problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

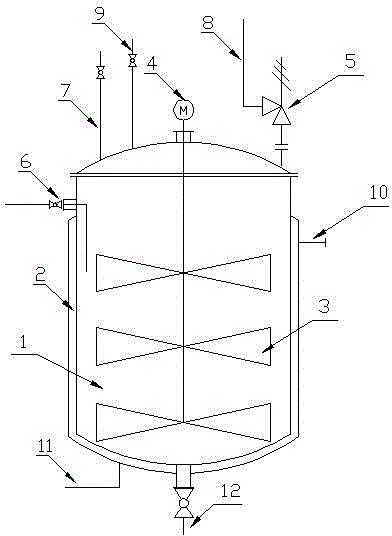

Image

Examples

Embodiment 1

[0022] Embodiment 1: The technical solution of the present invention will be further described through the following embodiments in conjunction with the accompanying drawings.

[0023] The chlorosilane waste liquid generated from polysilicon production is intermittently evaporated, and the lower boiling point of trichlorosilane and silicon tetrachloride is evaporated by controlling the temperature of the evaporator at 120°C-180°C and the pressure of 0.1-0.6MPa. into a gaseous state, and then sent to the rectification tower to be purified and recycled for reuse. The recovered waste liquid is mainly discharged from the bottom of the trichlorosilane synthesis scrubber to discharge chlorosilane containing aluminum chloride and metal chlorides and rectify in the rectification process The heavy components discharged from the tower equipment mainly contain a large amount of trichlorosilane and silicon tetrachloride. Under these operating conditions, the recovery rate of chlorosilane c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com