Method for improving raw coal sorting effect

A raw coal and sorting technology, applied in the direction of solid separation, can solve the problem that the sorting effect of the washing process cannot meet the production requirements, etc., and achieve the effect of improving the difficulty of coal slurry water treatment, improving the sorting effect, and reducing the jumping teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

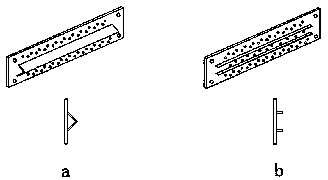

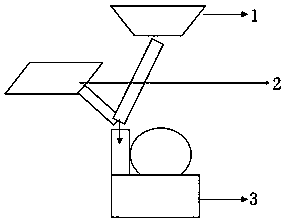

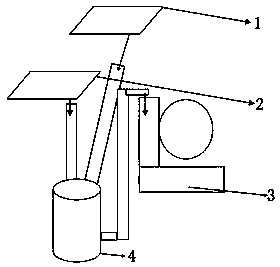

Image

Examples

Embodiment

[0025] This embodiment takes Dongzhouyao Coal Preparation Plant of Datong Coal Mine Group Co., Ltd. as an example:

[0026] Dongzhouyao Coal Preparation Plant is a mine-type steam coal preparation plant, designed to process 10 million tons of raw coal per year, with an hourly processing capacity of 1,894 tons per hour. The coal preparation process adopts graded full-dense medium separation, 50-200mm lump coal is separated by dense medium shallow tank separator; 50-1.5mm fine coal is separated by dense medium two-product cyclone; 1.5-0.15mm coarse coal Slime is sorted by screw separator; 0.15-0mm fine coal slime is recovered by pressure filter and plate and frame filter press.

[0027] In the actual production process, through the analysis of the coal quality, it is found that it is far from the initial stage of design, as shown in the following table:

[0028] 1. Natural grade sieving test report form

[0029]

[0030] 2. Comprehensive table of +50mm particle size coal fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com