III-series nitride semiconductor device and manufacturing method thereof

A nitride semiconductor and nitride technology, applied in the field of microelectronics, can solve the problems of increased leakage, current collapse, and current collapse effect of gallium nitride devices, and achieve the effect of reducing the current collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

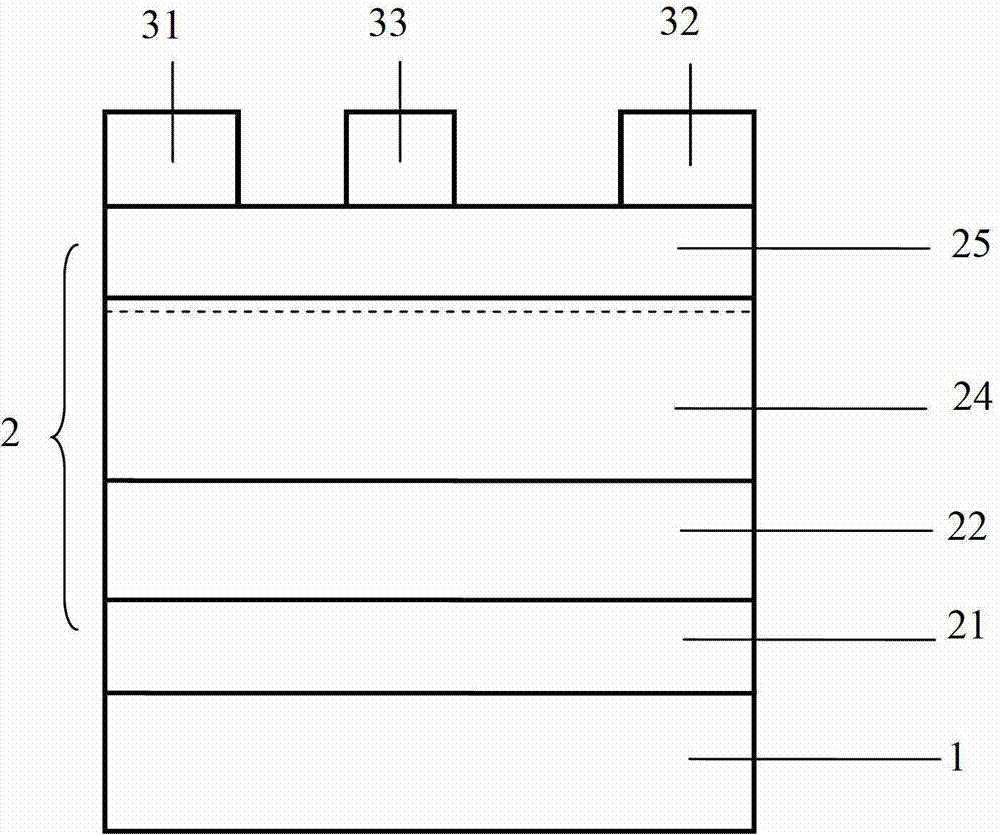

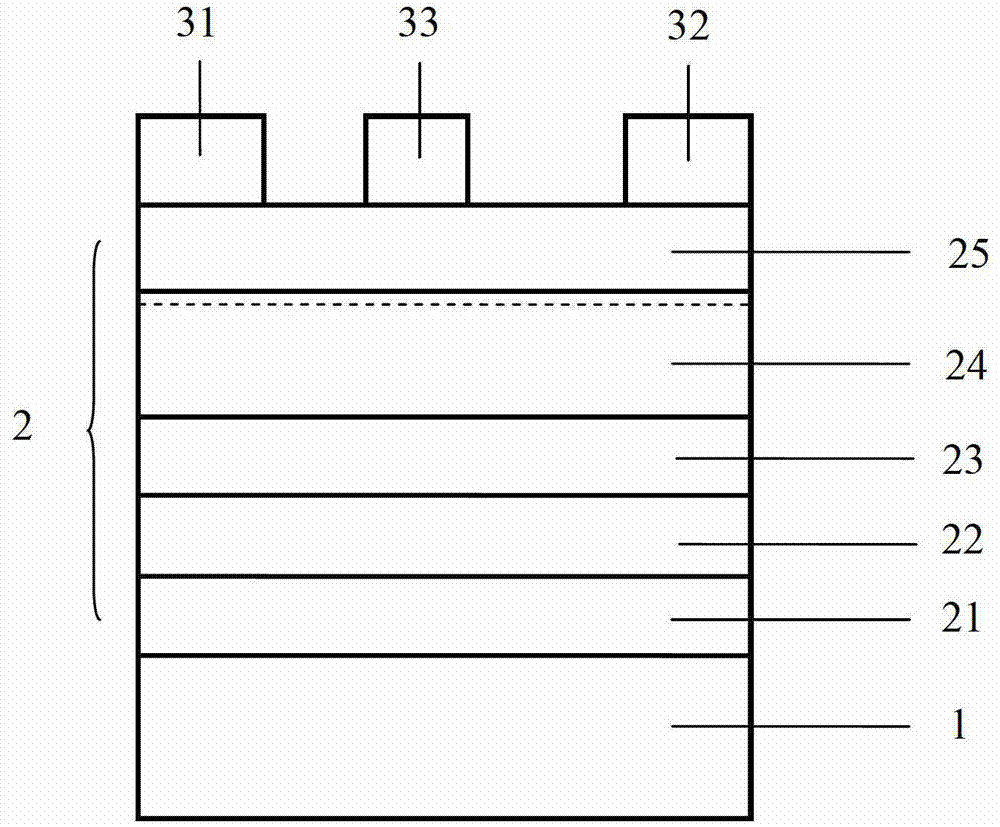

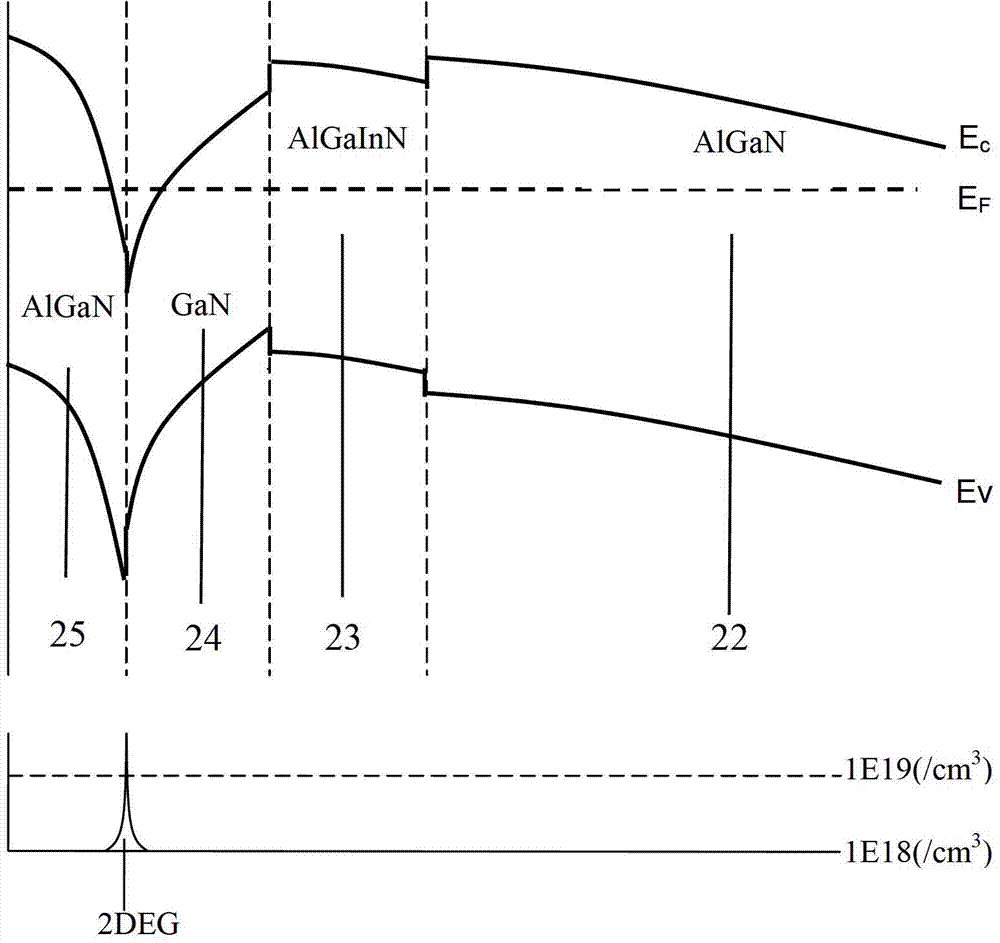

[0048] A group III nitride semiconductor device of the present invention, comprising:

[0049] Substrate;

[0050] a nitride nucleation layer on the substrate;

[0051] a nitride buffer layer on the nitride nucleation layer;

[0052] A wide-bandgap deep-level modulation layer on the nitride buffer layer;

[0053] A nitride channel layer on the wide bandgap deep level modulation layer;

[0054] and an electrode formed on the nitride channel layer;

[0055] Wherein, the wide-bandgap deep-level modulation layer is formed of a group III nitride semiconductor layer containing deep-level defects, and the concentration of the deep-level defects is a constant or increases from the nitride buffer layer to the nitride channel layer. Gradually decrease; the forbidden band width of the wide band gap deep energy level modulation layer is greater than the forbidden band width of the nitride channel layer.

[0056] Correspondingly, a method for manufacturing a Group III nitride semicond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com