Damping pad and single-phase motor mounting structure using same

A single-phase motor and installation structure technology, applied in asynchronous induction motors, electromechanical devices, electrical components, etc., can solve problems such as unsatisfactory vibration reduction effect, and achieve the purpose of reducing vibration and noise, improving sound quality, and reducing axial vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The single-phase motor installation structure of the present invention is applied to the fan motor installation of an embedded air conditioner. The fan motor is provided with four motor legs distributed in a rectangular shape and installed on a thin sheet metal plate. The motor is installed vertically to reduce vibration. The pad material is butyl rubber with large damping.

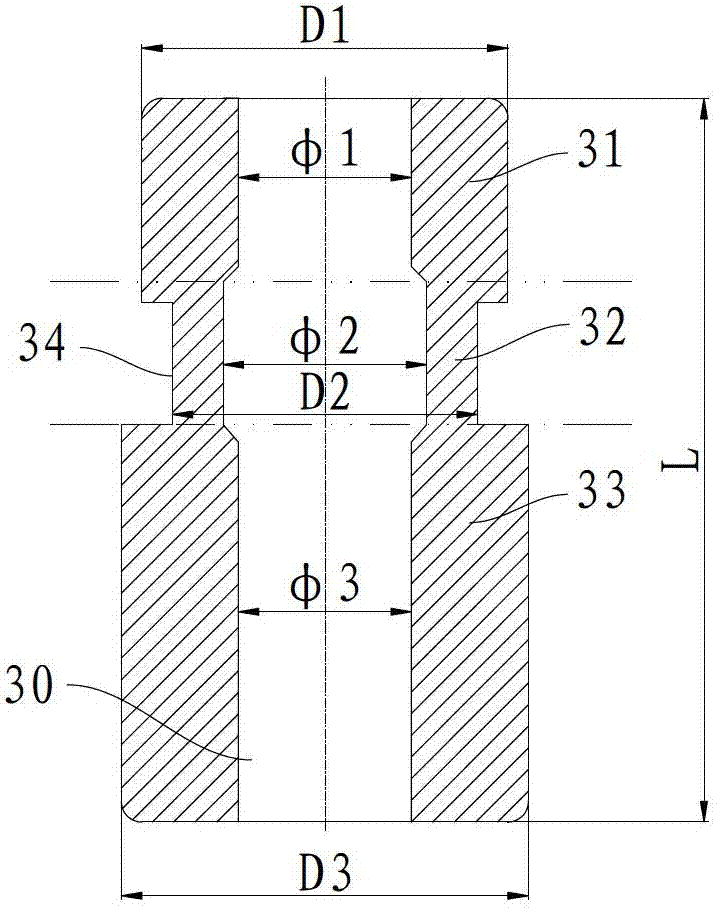

[0043] Such as Figure 1 ~ Figure 4 As shown, each motor support foot 4 of this single-phase motor all passes through the damping pad 3 of the present invention, the connecting bolt 1 used for fixing the motor, and supporting fasteners: special flat pad 5, spring pad 6, nut 7 and Install base 2 connections. The pad body of the vibration damping pad includes a vibration isolation section 32 in the middle and a first vibration isolation section 31 and a second vibration isolation section 33 respectively located at both ends of the vibration isolation section 32. The inner diameter φ2 of the vibratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com