Spline flywheel assembly for double-clutch automatic transmission

A technology of automatic transmission and dual clutch, applied in the direction of flywheel, etc., can solve the problems of slow speed increase, low transmission efficiency, and reduced driving pleasure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

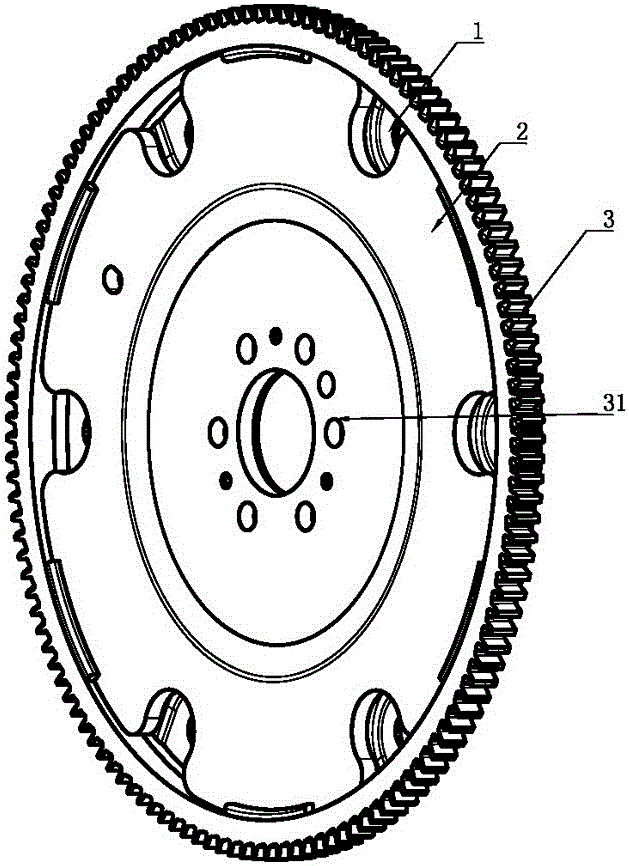

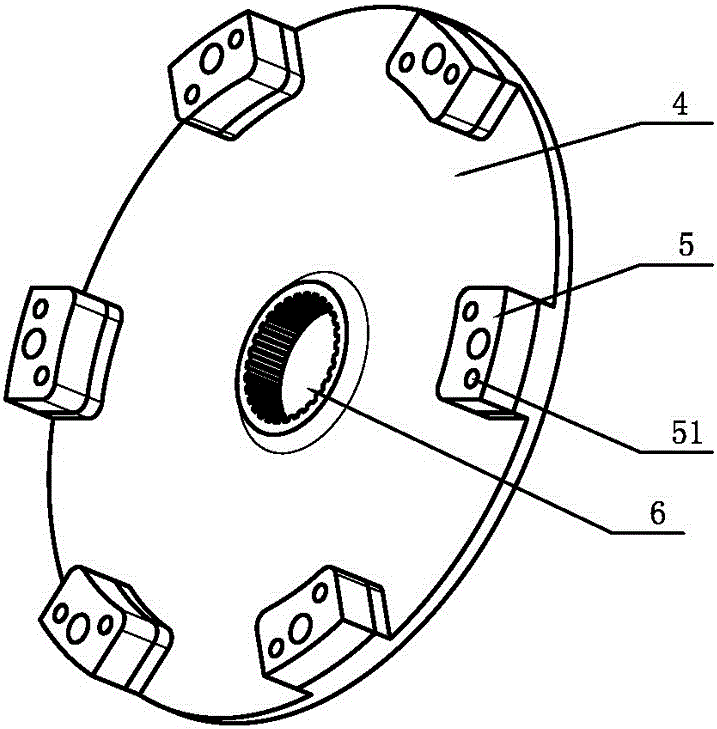

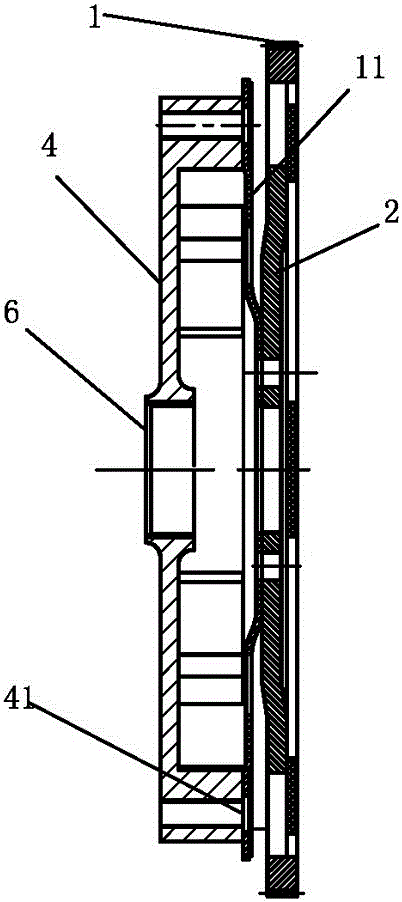

[0014] Depend on figure 1 , figure 2 , image 3 It can be seen that a spline flywheel assembly for dual-clutch automatic transmissions includes a spline flywheel 4 and a flexible flywheel disc 1. The spline flywheel 4 adopts a disc-shaped structure, and its outer ring is provided with a plurality of bosses 5 in the circumferential direction. The table 5 is provided with a threaded hole 51, and the center of the spline flywheel 4 disc is provided with a spline hole 6; the flexible flywheel disc 1 includes a connecting plate 2, and the connecting plate 2 and the flexible disc 11 are riveted by rivets, and the outer edge of the connecting plate 2 The ring gear 3 is sleeved, the crankshaft flange connecting hole 31 is provided on the connecting plate 2 and the flexible disc, and the spline flywheel connecting hole 41 corresponding to the threaded hole 51 on the boss is also provided on the flexible disc 11 .

[0015] During operation, the flexible flywheel disc 1 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com