Low boiling point working fluid circulation system for recovering blast furnace slag heat

A technology of low boiling point working fluid and blast furnace slag, applied in the field of machinery and equipment, can solve the problems of waste heat resource waste, low waste heat resource recovery efficiency, waste of hot water thermal energy slag radiant heat and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] see Attachment

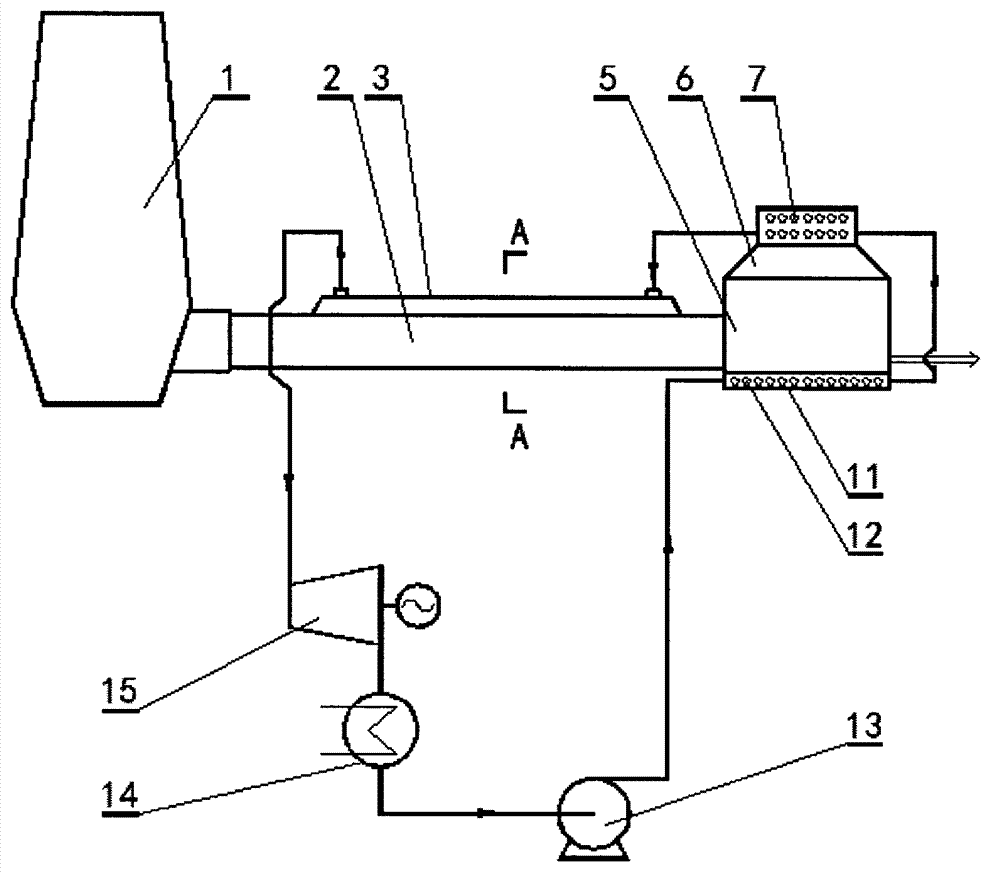

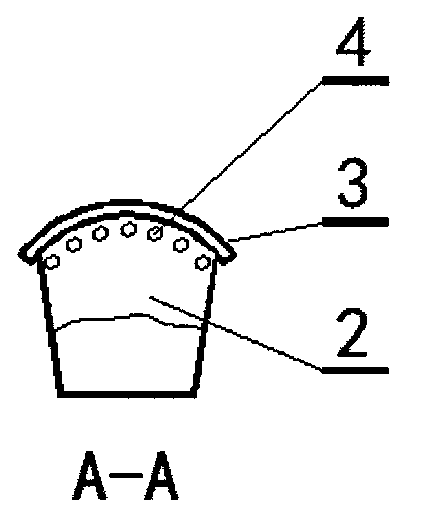

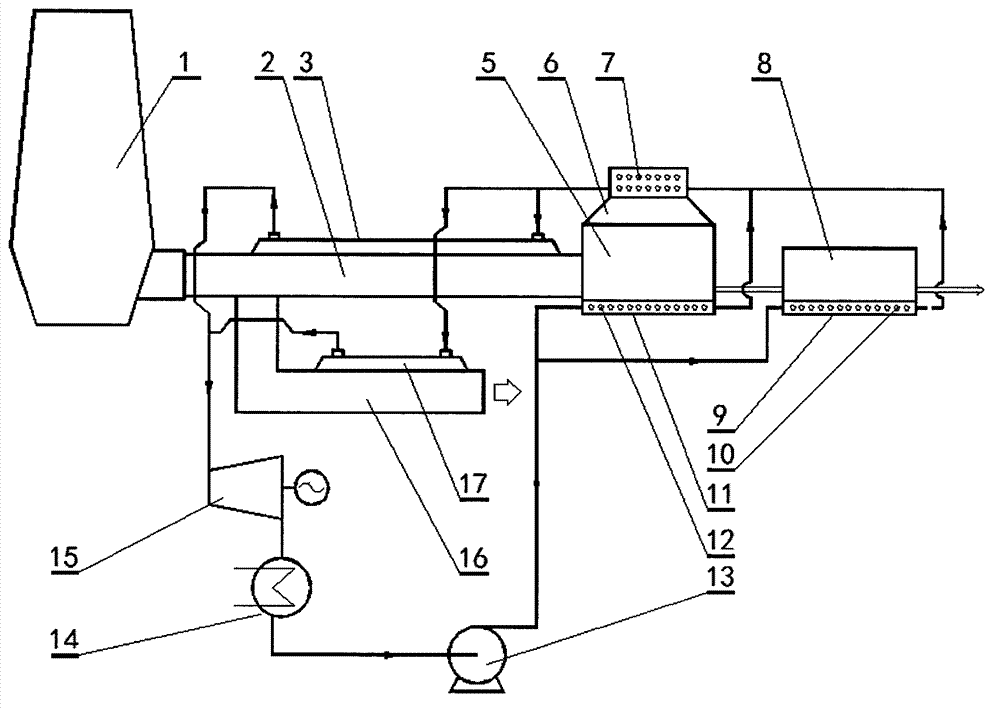

[0018] A low-boiling-point working medium circulation system for recovering heat energy of blast furnace slag, comprising a blast furnace 1, a slag ditch 2 connected to the blast furnace 1, and a punch box 5 connected to the slag ditch 2. The high-temperature molten slag at the outlet of the blast furnace 1 flows into the punching box 5 through the slag ditch 2, where it is punched by high-pressure water in the punching box 5, and then it is rapidly cooled and solidified to form water slag. A low-boiling-point working fluid heat radiation device 3 is arranged above the slag ditch 2. The low-boiling point working fluid heat radiation device 3 is arc-shaped, and low-boiling point working fluid heat radiation devices 3 are evenly arranged and connected to each other on the inner surface of the low-boiling point working fluid heat radiatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com