Apparatus and method for preparing deuterium depleted water

A preparation device, ultra-light water technology, applied in heavy water and other directions, can solve the problem of no ultra-light water, etc., and achieve the effects of improving the film hanging performance, increasing the separation power, and reducing the height

Active Publication Date: 2010-11-10

SHANGHAI RES INST OF CHEM IND +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there are few technical reports on the industrial-scale preparation of ultra-light water by distillation, and there is no related technology for the preparation of ultra-light water from the heavy oxygen water residue.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

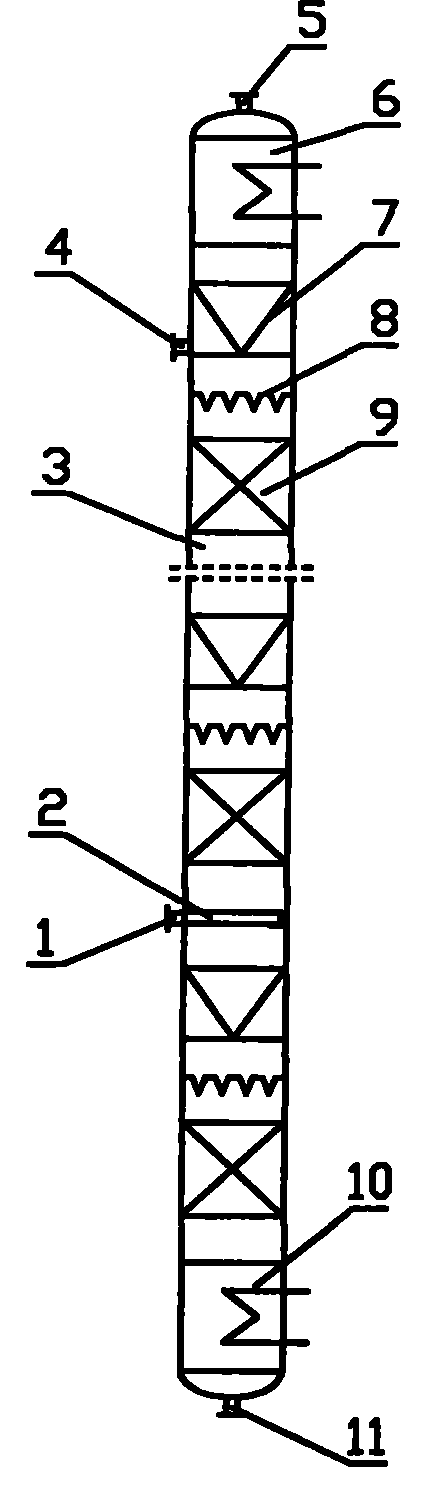

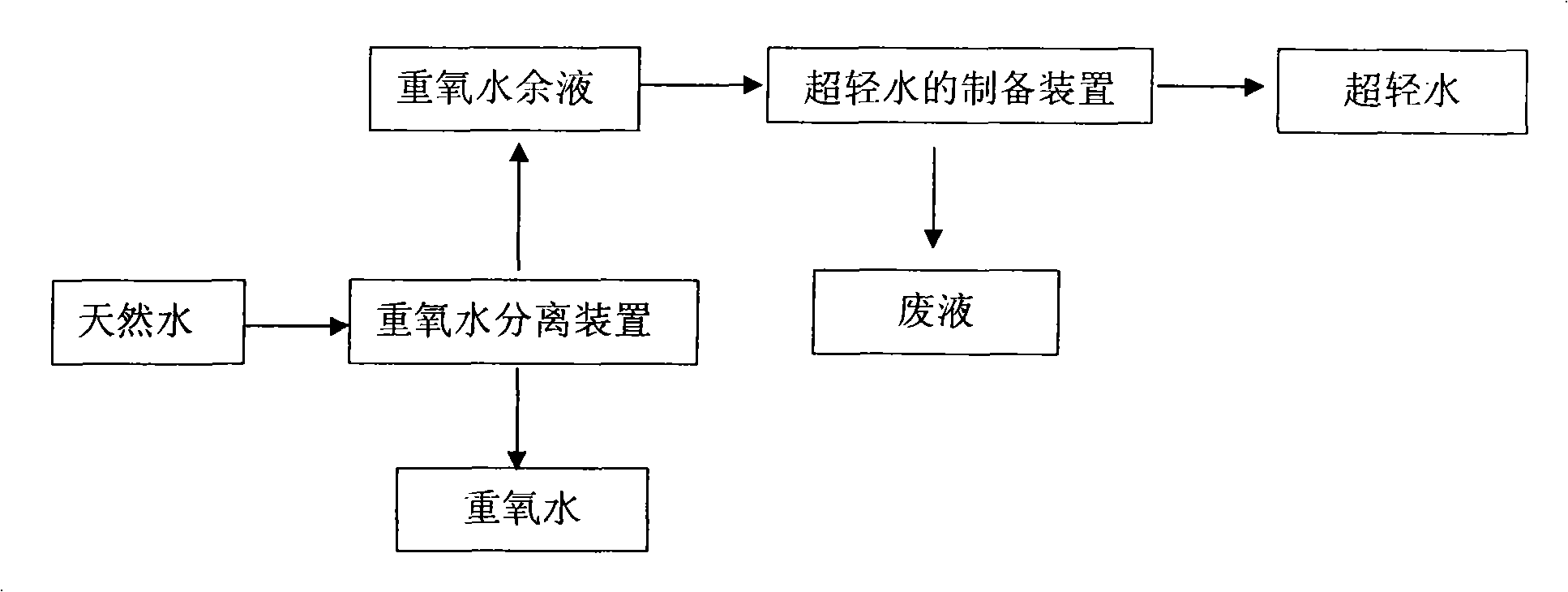

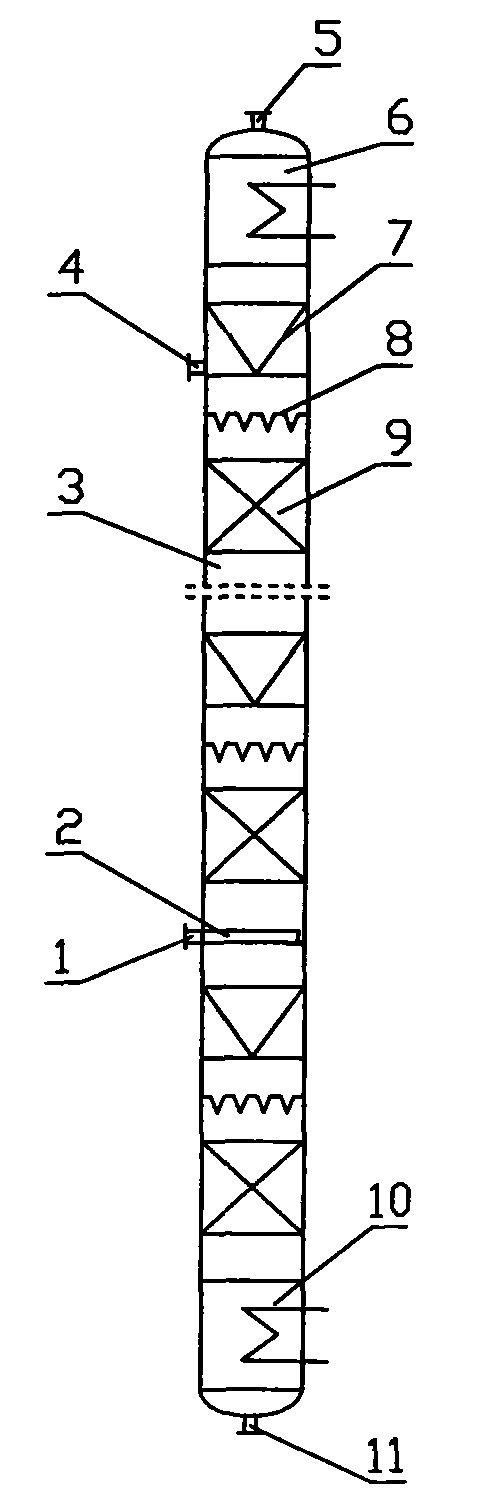

Abstract

The invention relates to a device for preparing super light water, in particular to a device for preparing super light water using a distillation separating method. The invention further relates to a method for preparing super light water by adopting the device. The device for preparing super light water comprises a composite distillation tower which comprises a tower body and a condensing area, a heating area and a mass transferring area arranged inside the tower body, wherein the condensing area is arranged at the upper end inside the tower body, the heating area is arranged at the lower end inside the tower body, and the mass transferring area is arranged between the condensing area and the heating area. The method for preparing the super light water of the invention takes heavy oxygenwater residual liquid or natural water as raw material, and makes the raw material flow into the composite distillation tower of the device for preparing the super light water to obtain the super light water. Compared with the prior art, the invention has the characteristics of saving energy, reducing the consumption, lowering the operating cost and reducing the investment fees, and further has simple process, high separation efficiency of the distillation tower and simple and easily controlled production operation.

Description

A kind of preparation device of ultra-light water and the preparation method of ultra-light water technical field The invention relates to a preparation device for ultra-light water, in particular to a device for preparing ultra-light water by distillation and separation, and also relates to a method for preparing ultra-light water by using the preparation device. Background technique Ultra-light water, also known as deuterium-depleted water or deuterium-depleted water, is a new high-tech stable isotope product that has emerged in the field of nuclear medicine abroad in recent years. It is mainly used to prepare high-purity protium gas, nuclear magnetic resonance solvent, and drinking water for the prevention and treatment of cancer and other diseases and health care. The separation principle of ultra-light water is the same as that of heavy water. Therefore, according to the separation principle, any separation method suitable for heavy water, such as chemical exchange m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B5/02

Inventor 张丽雅秦川江陈大昌周建跃肖斌李猷姜永悦刘严

Owner SHANGHAI RES INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com