Soaping compound enzyme and application method thereof

A composite enzyme, soaping technology, applied in detergent compositions, chemical instruments and methods, non-surface-active detergent compositions, etc., can solve the problem that the wet rubbing fastness of dark dyed fabrics is not obvious, and the dyeing shade changes. It can improve the soaping effect, shorten the process time and save water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

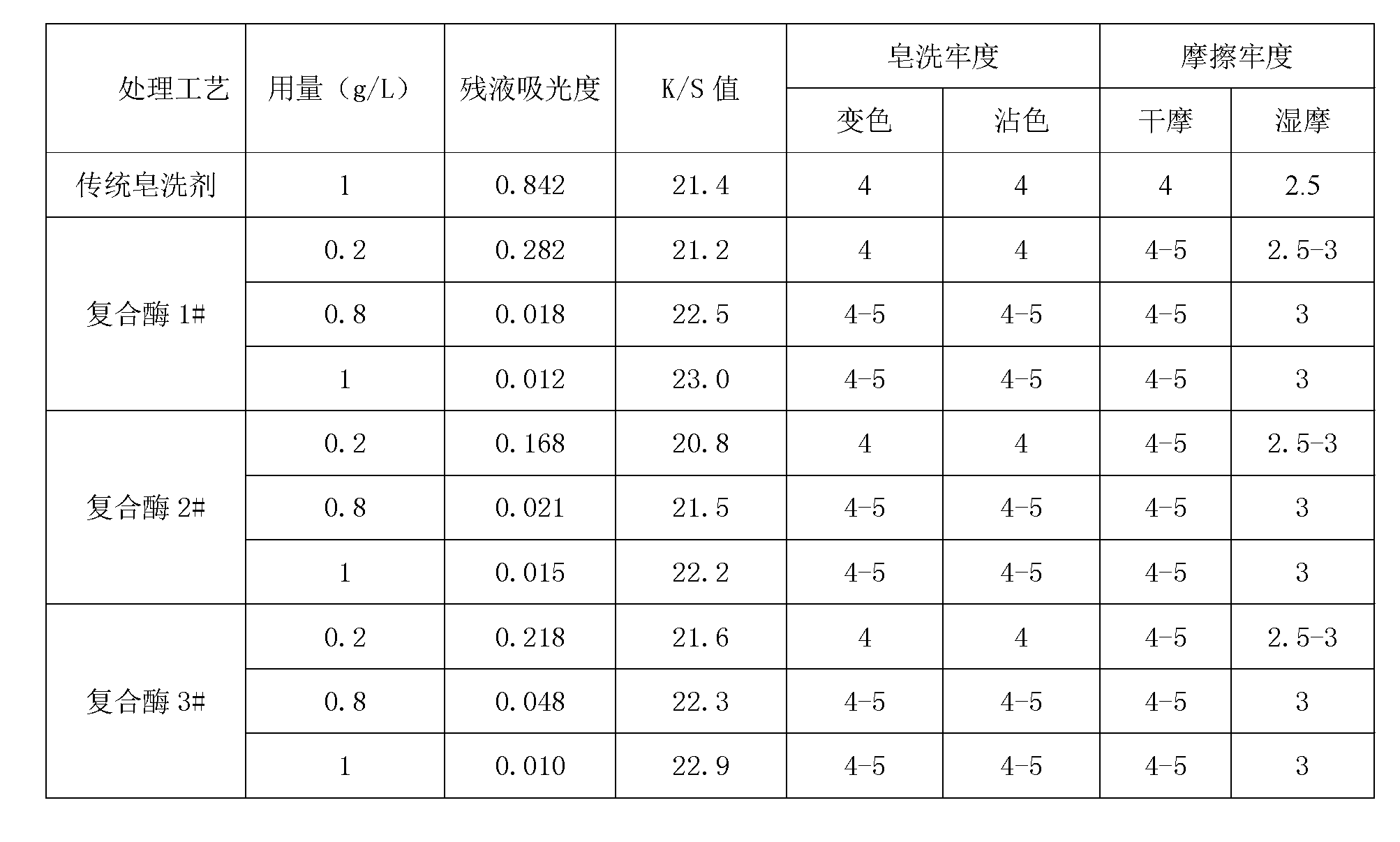

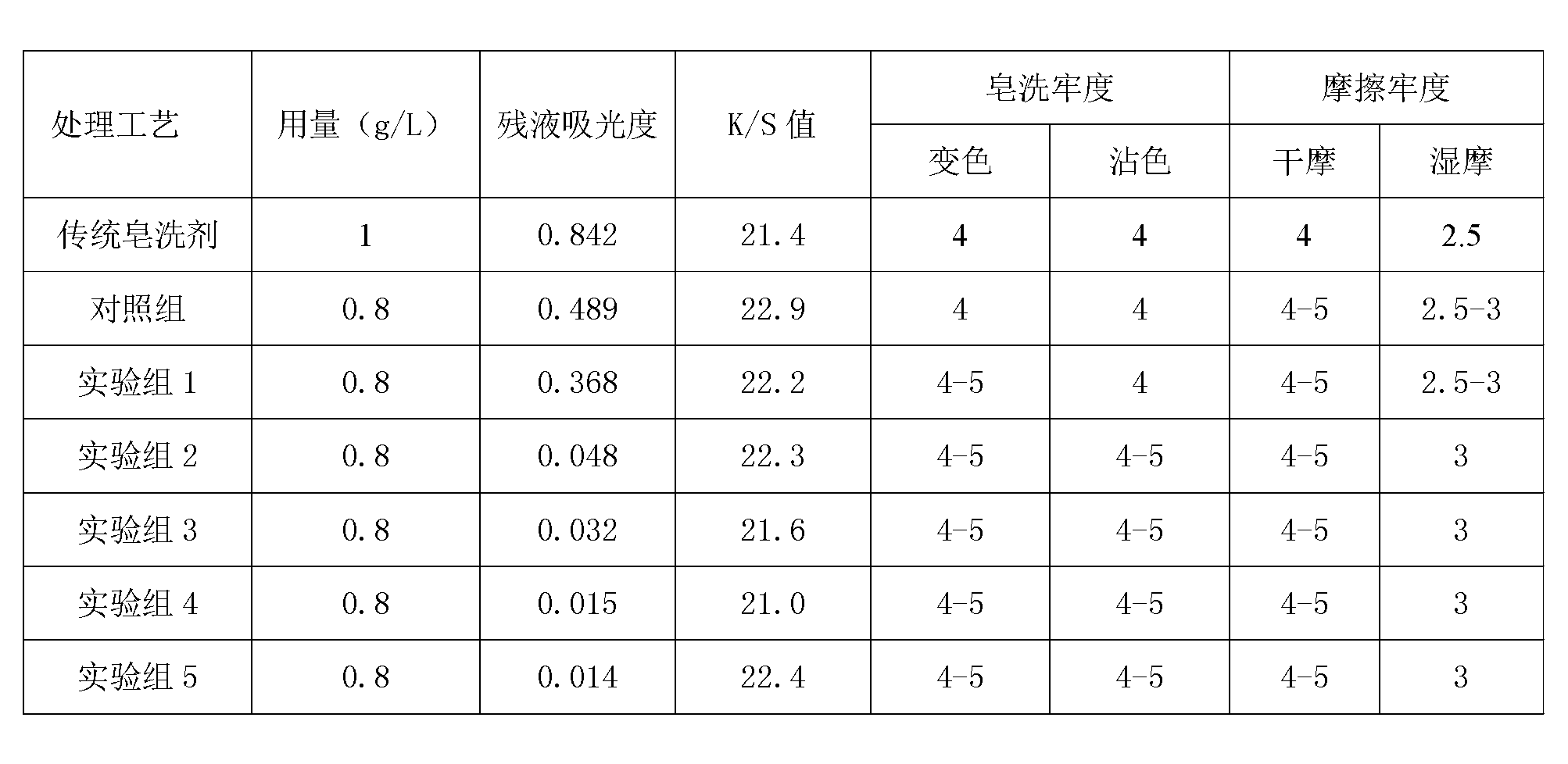

Embodiment 1

[0017] The components and mass ratios of the composite enzyme for soaping are: 55% laccase, 30% sodium persulfate, 10% polyvinylpyrrolidone, and 5% sodium citrate. In an aseptic environment, use a mechanical mixer to mix the above-mentioned components in proportion to make compound enzyme 1#, totaling 1 kg. The appearance of the composite enzyme is off-white particles.

Embodiment 2

[0019] The components and mass ratios of the composite enzyme for soaping are: 80% laccase, 15% potassium persulfate, 4% polyvinylpyrrolidone, and 1% sodium citrate. In a sterile environment, use a mechanical mixer to mix the above-mentioned components in proportion to make compound enzyme 2#, totaling 1 kg. The appearance of the composite enzyme is off-white particles.

Embodiment 3

[0021] The components and mass ratios of the composite enzyme for soaping are: 70% laccase, 20% ammonium persulfate, 7% polyvinylpyrrolidone, and 3% sodium citrate. In an aseptic environment, use a mechanical mixer to mix the above-mentioned components in proportions to make compound enzyme 3#, totaling 1 kg. The appearance of the composite enzyme is off-white particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com