Cerium-based mischmetal polishing material and preparation method thereof

A technology of mixing rare earth and polishing materials, which is applied in the field of rare earth polishing materials and its preparation, and can solve problems such as unfavorable use, poor suspension of polishing powder, and easy foaming of surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

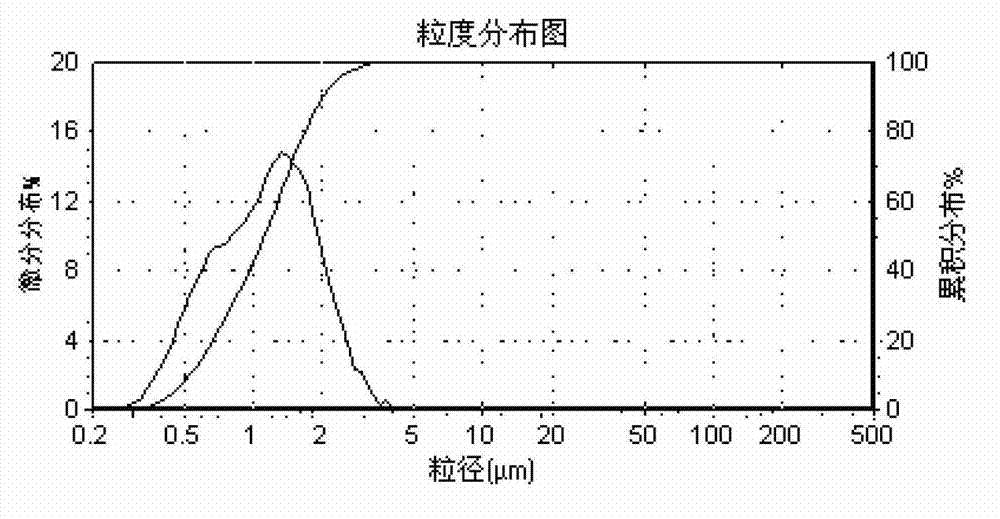

Image

Examples

preparation example Construction

[0028] The preparation method of the rare earth polishing material of the present invention comprises the following steps: preparing the cerium-based rare earth polishing powder, clay and polycarboxylic acid compound by dry ball milling in proportion.

[0029] In the present invention, the dry ball milling is carried out by using a ball mill; the milling time of the dry ball milling is 0.5-2h.

[0030] The purpose of the dry ball milling is to fully mix the components such as the cerium-based rare earth polishing powder, clay and polycarboxylate compound.

Embodiment 1

[0032] The cerium-based rare earth polishing powder, clay and polycarboxylate compound are dry-milled using TOSHIBA E658157 ball mill according to the proportion. Table 1 shows the components and contents of the cerium-based mixed rare earth polishing material of the present invention.

[0033]

Embodiment 2

[0035] The polishing performance evaluation conditions and evaluation results of the cerium-based mixed rare earth polishing material of the present invention are as follows:

[0036] Each polish prepared according to Table 1 was evaluated for application performance.

[0037] The evaluation method is as follows:

[0038] Take 500 g of the rare earth polishing material, add deionized water to 5 L, and obtain a polishing liquid slurry with a concentration of 100 g / L. Use UNIPOL802 (Shenyang Kejing) precision grinding and polishing machine to polish K9 glass, automatic stirring and beating, filtration and recycling, the polishing machine shaft speed is 100 rpm, and the pressure is 660N / cm 2 , The polishing leather is KSP66B-1.25, the polishing time is 6.5 hours, the particle size of the slurry is tested at regular intervals and the weight of the washed and dried glass is recorded. The difference is calculated according to the mass of the weighing polishing element before and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com