Heavy-duty art paint for nuclear power plant electric instrument cases and preparation method thereof

A technology for instrument cabinets and nuclear power plants, applied in anti-corrosion coatings, art coatings, coatings, etc., can solve the problems of orange-patterned paints that are prone to yellowing and aging, and achieve stable and reliable anti-rust and anti-corrosion performance, good anti-corrosion effect, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Paint recipe:

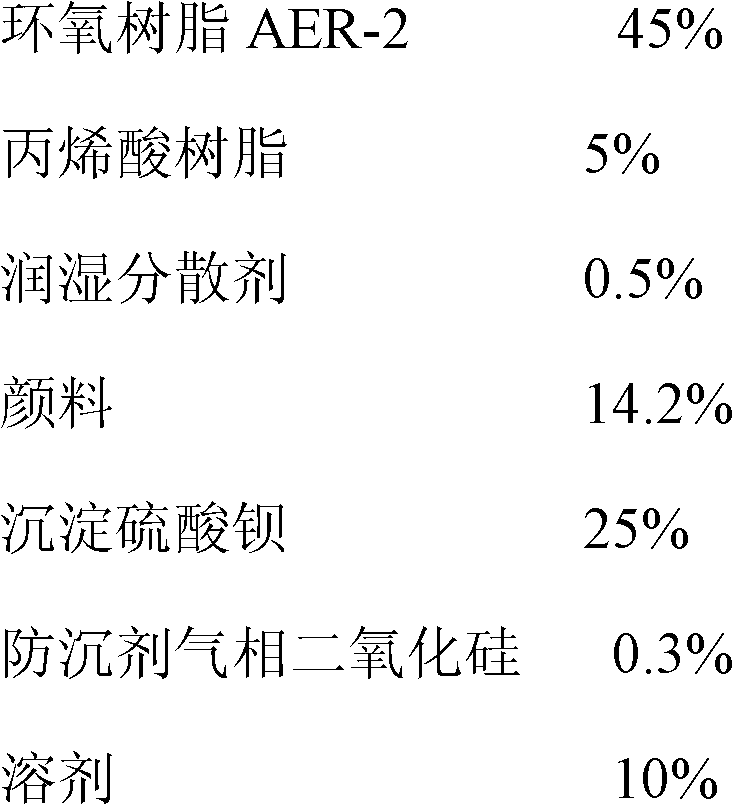

[0046] The weight percent of A component is as follows:

[0047]

[0048] The pigment is a mixture of titanium dioxide, phthalocyanine blue and carbon black in a weight ratio of 14:1:0.1;

[0049] Described solvent is the mixture of xylene and butanol, and weight ratio is 1: 1;

[0050] The weight percent of B component is as follows:

[0051] ET-305 polyamide curing agent 52%

[0052] Xylene 48%

[0053] Preparation:

[0054] Epoxy resin and part of the solvent are heated and dissolved so that the solid weight content is 60%;

[0055] Add pigments, fillers, additives and the rest of the solvent, mix and disperse, then add acrylic resin to obtain component A, apply 4 cups, and the viscosity of component A at 25°C is 110 seconds;

[0056] Mix and disperse the polyamide epoxy curing agent and xylene to obtain component B;

[0057] When used, according to the weight ratio of 5-10:1, stir and mix, and use up within 4 hours.

[0058] The standard "...

Embodiment 2

[0061] Paint recipe:

[0062] The weight percent of A component is as follows:

[0063]

[0064] The pigment is a mixture of titanium dioxide and chrome yellow pigment in a weight ratio of 1:1;

[0065] Described solvent is the mixture of xylene and butanol, and weight ratio is 1: 1;

[0066] The weight percent of B component is as follows:

[0067] Versmid 115×70 52%

[0068] Xylene 48%

[0069] Preparation:

[0070] Epoxy resin and part of the solvent are heated and dissolved so that the solid weight content is 60%;

[0071] Add pigments, fillers, additives and the rest of the solvent, mix and disperse, then add acrylic resin to obtain component A, apply 4 cups, and the viscosity of component A at 25°C is 110 seconds;

[0072] Mix and disperse the polyamide epoxy curing agent and xylene to obtain component B;

[0073] When used, according to the weight ratio of 5-10:1, stir and mix, and use up within 4 hours.

[0074] Compared with "Q / GHTD 10-2004 F17-51 Phenolic Dr...

Embodiment 3

[0078] Paint recipe:

[0079] The weight percent of A component is as follows:

[0080]

[0081] The pigment is a mixture of titanium dioxide, phthalocyanine blue and tartrazine pigments in a weight ratio of 7:1:0.5;

[0082] Described solvent is the mixture of xylene and butanol, and weight ratio is 1: 1;

[0083] The weight percent of B component is as follows:

[0084] Versmid 115×70 52%

[0085] Xylene 48%

[0086] Preparation:

[0087] Epoxy resin and part of the solvent are heated and dissolved so that the solid weight content is 60%;

[0088] Add pigments, fillers, additives and the rest of the solvent, mix and disperse, then add acrylic resin to obtain component A, apply 4 cups, and the viscosity of component A at 25°C is 100 seconds;

[0089] Mix and disperse the polyamide epoxy curing agent and xylene to obtain component B;

[0090] When used, according to the weight ratio of 5-10:1, stir and mix, and use up within 4 hours.

[0091] Compared with "Q / GHTD 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com