Resin composition and resin-molded product

A resin composition and resin molding technology, applied in the field of resin composition and resin molded products, can solve the problems of using cellulose derivatives, etc., and achieve the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20 and comparative example 1~12

[0159] The ingredients shown in Tables 1 to 5 were kneaded with a biaxial kneader (manufactured by TOSHIBA MACHINE CO., LTD., TEM58SS) at a cylinder temperature of 210°C, thereby obtaining pellets of the resin composition.

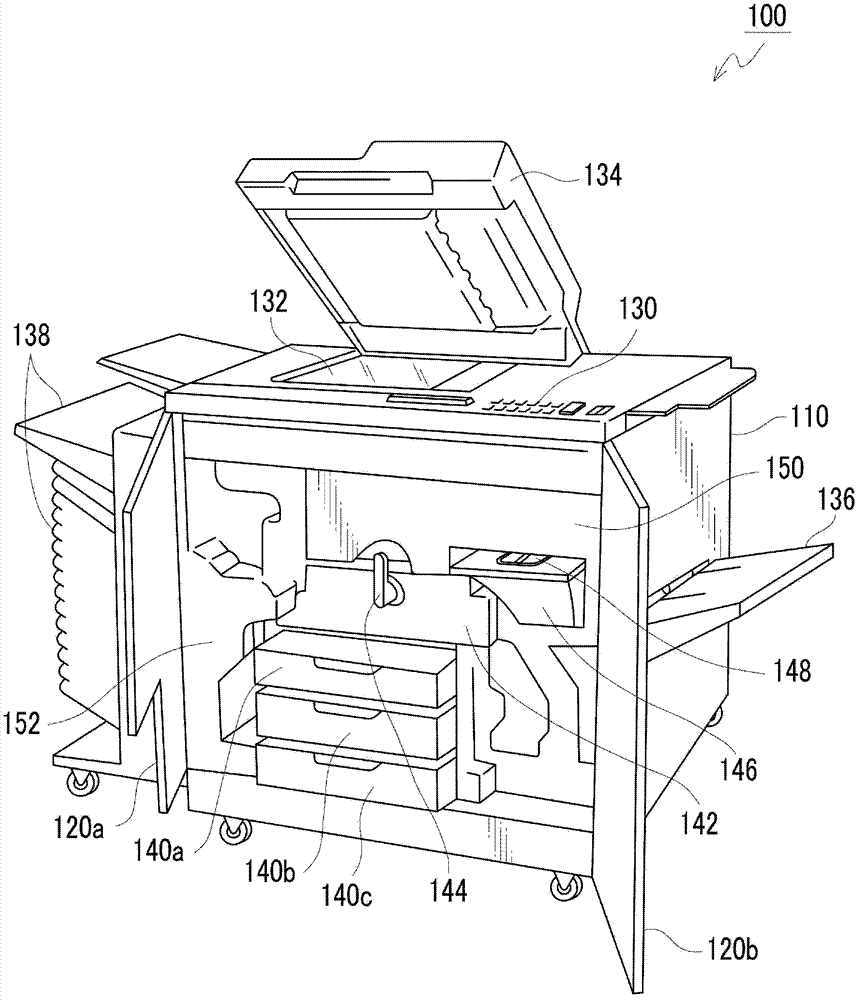

[0160] The obtained pellets were injection-molded using an injection molding machine (manufactured by Nissei Plastic Industrial Co., Ltd., product name "NEX500") at the cylinder temperatures shown in Tables 1 to 5 and at a mold temperature of 50°C , thus forming the ISO multi-purpose dumbbell test sample (corresponding to ISO527 tensile test and ISO178 bending test, the thickness of the test part is 4mm, the width is 10mm) and the UL test sample (thickness is 1.6mm) for the V test in UL-94 ).

[0161] [Evaluate]

[0162] (plant source content)

[0163] The plant-derived content of the resin composition used in each example was calculated by the following formula.

[0164] Formula: plant source content=quality of cellulose acetate propionate×(quality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com