Method for solidifying and stabilizing sludge from urban sewage treatment plant

A technology for solidifying urban sewage and sludge, applied in the field of environmental engineering, can solve problems such as large amount of cement and lime mixed, increase sludge disposal volume, reduce moisture content, etc., so as to reduce pollution problems and treatment costs, and realize resource utilization. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

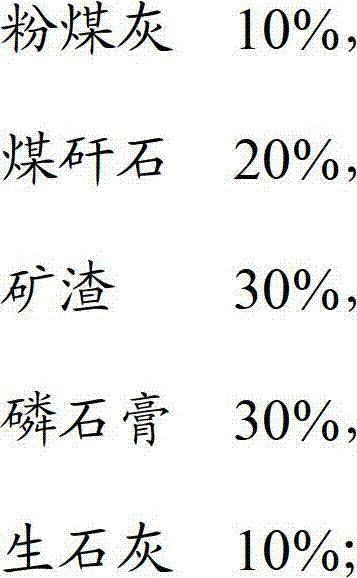

[0013] 1) Preparation of industrial waste residue mixture: Mix fly ash, coal gangue, slag, phosphogypsum, and quicklime evenly, and the weight ratio of each component is as follows:

[0014]

[0015] 2) Preparation of curing stabilizer: mix the industrial waste residue mixture and portland cement evenly, and the weight ratio of each component is as follows:

[0016] Industrial waste 45%,

[0017] Portland cement 55%;

[0018] 3) Send the sludge and the solidified stabilizer into the mixer with a screw conveyor, in which the solidified stabilizer accounts for 5% of the total weight of the sludge. After mixing it thoroughly for 10-15 minutes, pump the solidified sludge out to Nursery;

[0019] 4) After curing the solidified sludge in the curing field for 7 days, the moisture content of the solidified sludge is 55.2%, lower than 60%, the unconfined compressive strength is 217.8Kpa, and the concentrations of heavy metals in the leachate are all lower than the relevant standar...

Embodiment 2

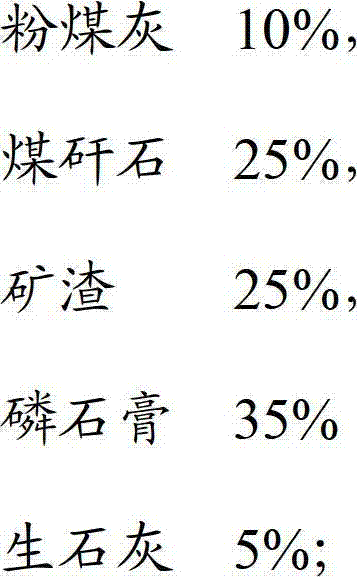

[0021] 1) Preparation of industrial waste residue mixture: Mix fly ash, coal gangue, slag, phosphogypsum, and quicklime evenly, and the weight ratio of each component is as follows:

[0022]

[0023] 2) Preparation of curing stabilizer: mix the industrial waste residue mixture and portland cement evenly, and the weight ratio of each component is as follows:

[0024] Industrial waste 50%,

[0025] Portland cement 50%;

[0026] 3) Send the sludge and solidified stabilizer into the mixer with a screw conveyor, in which the solidified stabilizer accounts for 8% of the total weight of the sludge. After fully mixing for 10-15 minutes, use a pump to pump out the solidified sludge until curing field;

[0027] 4) After curing the solidified sludge in the curing field for 7 days, the moisture content of the solidified sludge is 46.8%, lower than 60%, the unconfined compressive strength is 332.5Kpa, and the concentration of heavy metal substances in the leachate is lower than the re...

Embodiment 3

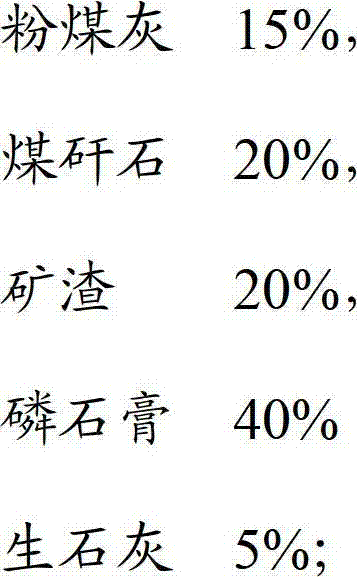

[0029] 1) Preparation of industrial waste residue mixture: Mix fly ash, coal gangue, slag, phosphogypsum, and quicklime evenly, and the weight ratio of each component is as follows:

[0030]

[0031] 2) Preparation of curing stabilizer: mix the industrial waste residue mixture and portland cement evenly, and the weight ratio of each component is as follows:

[0032] Industrial waste 55%,

[0033] Portland cement 45%;

[0034] 3) Send the sludge and solidified stabilizer into the mixer with a screw conveyor, in which the solidified stabilizer accounts for 10% of the total weight of the sludge. After fully mixing for 10-15 minutes, use a pump to pump out the solidified sludge until curing field;

[0035] 4) After curing the solidified sludge in the curing field for 7 days, the moisture content of the solidified sludge is 45.7%, lower than 60%, the unconfined compressive strength is 395Kpa, and the concentration of heavy metal substances in the leachate is lower than the rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com