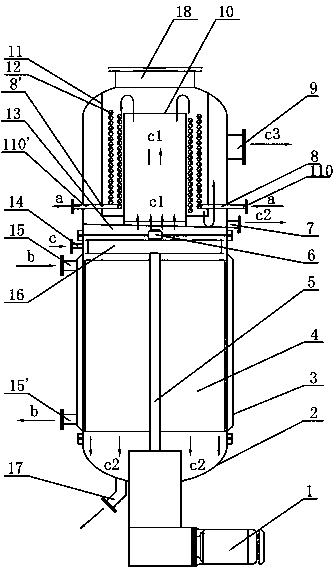

Wiped film distiller

A wiped film distillation and distributor technology, applied in the field of stills, can solve the problems of mist entrainment, short vapor phase stroke, low vacuum degree of evaporation film surface operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Example 1: In the separation of mixed paraffins (polycarbon alcohols C12---C26), the purity of the light component C12 obtained after adopting the present invention is much higher than that obtained by the traditional short-path distiller, and the light component There is no high-boiling point alcohol in the part, and the separation effect is much better than that of the traditional short-path still.

[0022] The agitating drive mechanism and the agitating film-forming device are all known structures, and their working principle is the same as that of the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com