Novel technical scheme for producing LED (Light Emitting Diode) soft light bar

A soft light strip, LED chip technology, applied in the field of LED landscape and decorative lighting applications, can solve the problems of short service life, high cost, poor heat dissipation, etc., and achieve the effect of long service life, low cost and great social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Below with reference to accompanying drawing of specification sheet ①-(12), present embodiment is described further:

[0046] 1. The electronic components (M2) are mounted on the flexible PCB (M1) by welding technology, as shown in Figure ②;

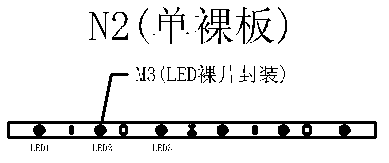

[0047] 2. The LED chip is fixed on the flexible PCB board (M1) by bonding technology to form an LED bare chip package and form a single bare board N2, as shown in Figure ④;

[0048] 3. Multiple single bare boards (N2) are welded end to end to form a multi-bare board (N3) as shown in Figure ⑤;

[0049] 4. Solder electronic wires at one or both ends of the multi-bare board (N3) to form a multi-bare board half product (N5) as shown in Figure ⑦;

[0050] 5.1) Multi-bare board semi-products (N5) without cladding constitute product P1; as shown in Figure ⑧

[0051] 2) Multi-bare board semi-products (N5) penetrate the silicone sleeve to form product P2; as shown in Figure ⑨

[0052] 3) Multi-bare board semi-product (N5) components are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com