An electronic ink display screen and manufacturing method thereof

A technology of electronic ink and manufacturing method, which is applied in the fields of instruments, nonlinear optics, optics, etc., can solve the problems of difficult electronic paper membrane packaging technology, high use cost, unstable process, etc., and achieve rich driving schemes and display effects , Waterproof and sealing performance improvement, the effect of excellent color resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0055] The present invention is not limited to the following embodiments, and the figures referred to in the following description are provided for understanding the content of the present invention, that is, the present invention is not limited to the structure of the electronic ink display screen exemplified in each figure.

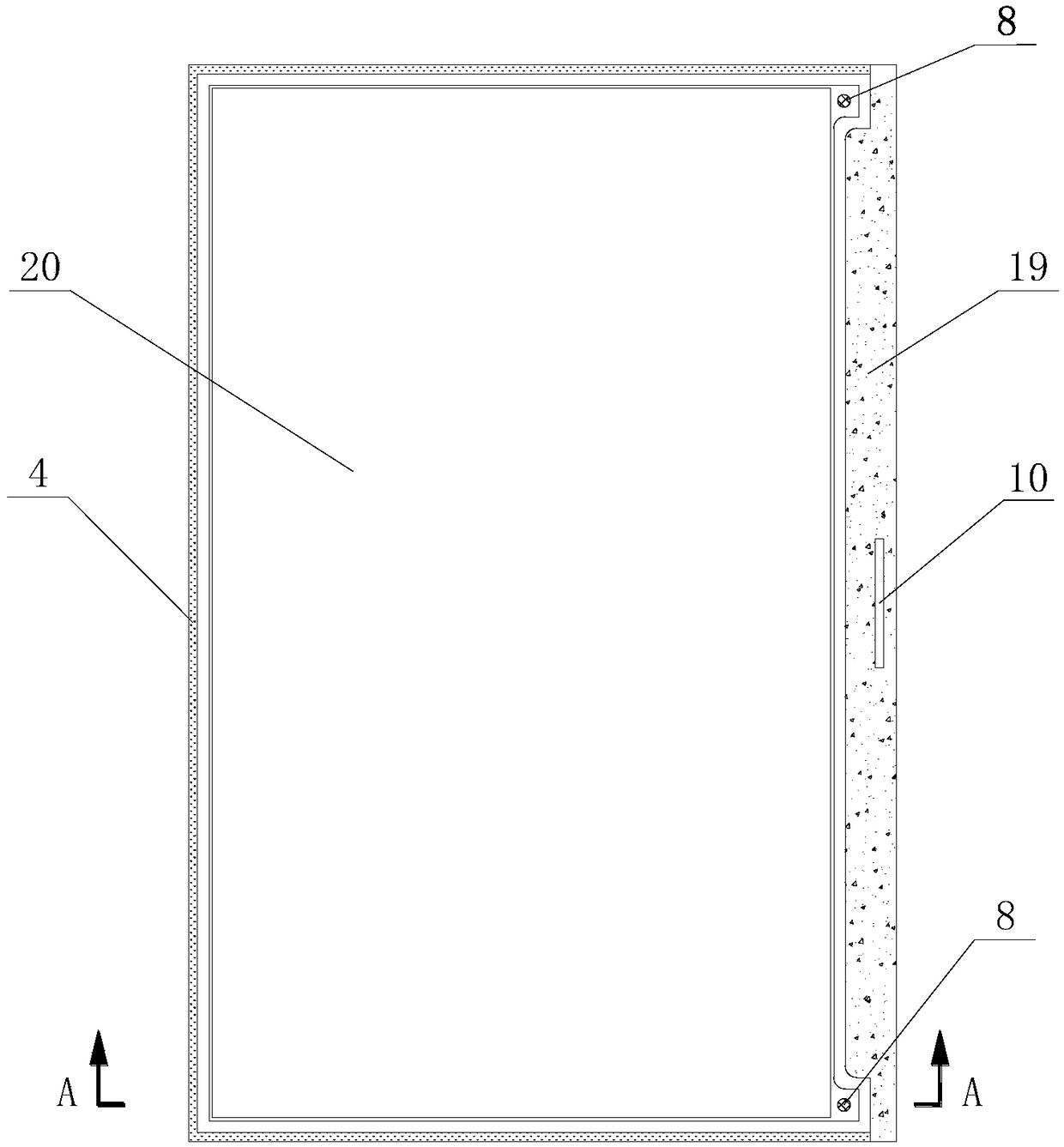

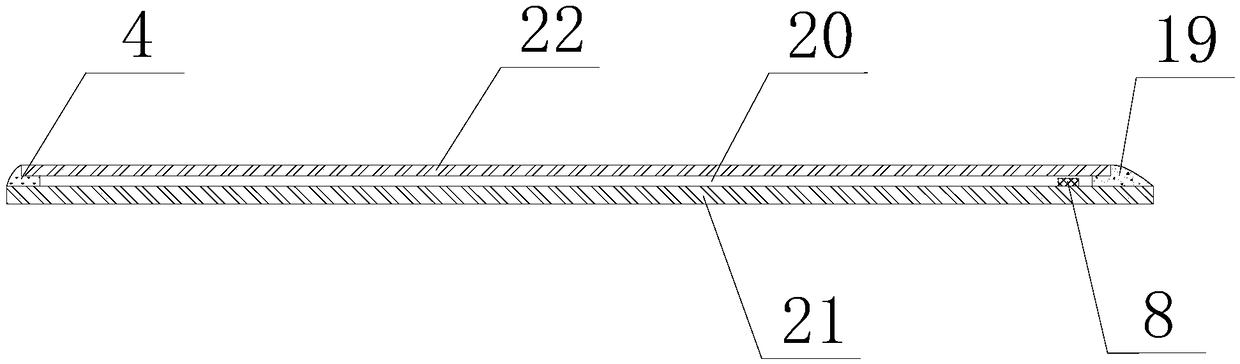

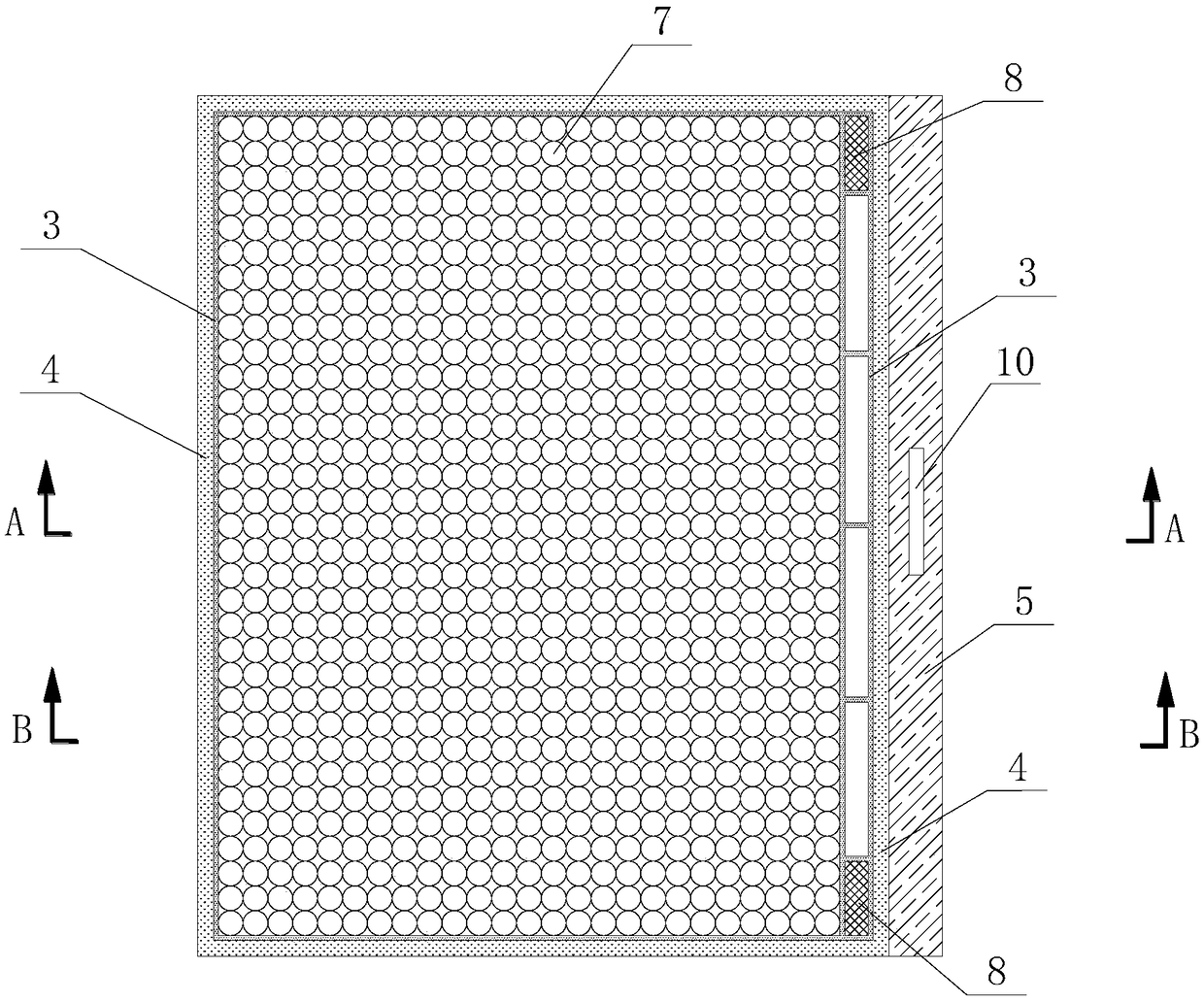

[0056] as attached Figure 3~5 As shown, Embodiment 1 takes a two-particle electronic ink display screen as an example. An electronic ink display screen includes a pixel electrode 5, an electronic ink microcapsule array 7 and an upper transparent electrode, and the electronic ink microcapsule array 7 is arranged on the pixel Between the electrode 5 and the upper transparent electrode, it is characterized in that the pixel electrode 5 includes a segment code and a dot matrix, and the material of the pixel electrode is glass or plastic, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com