Geomembrane with double coarse surfaces

A technology of geomembrane and rough surface, which is applied in the direction of infrastructure engineering, protective devices, buildings, etc., can solve the problems of affecting welding fastness, increasing construction hours, and increasing welding seams, so as to improve the quality of lap welding, save materials and The effect of increased working hours and frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

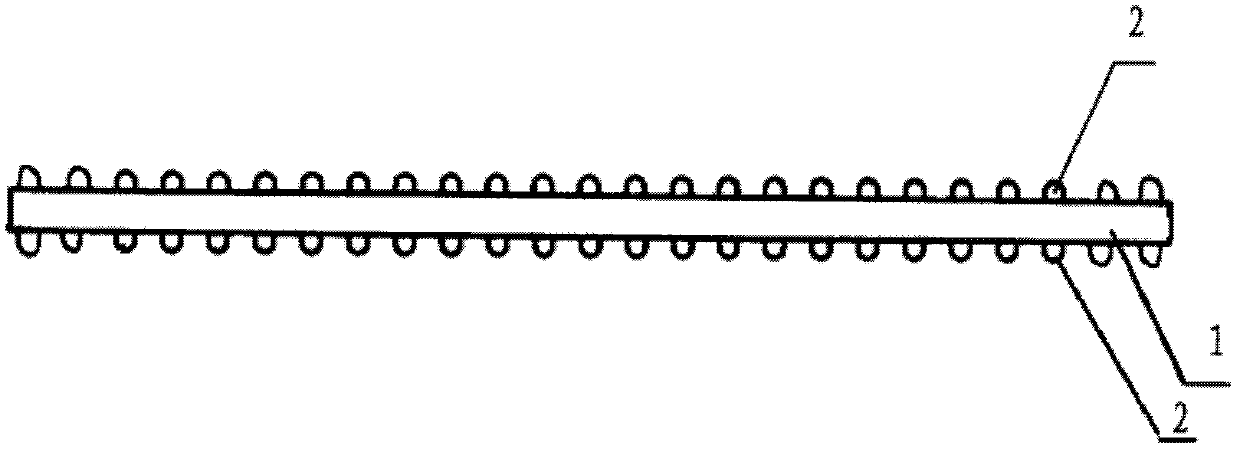

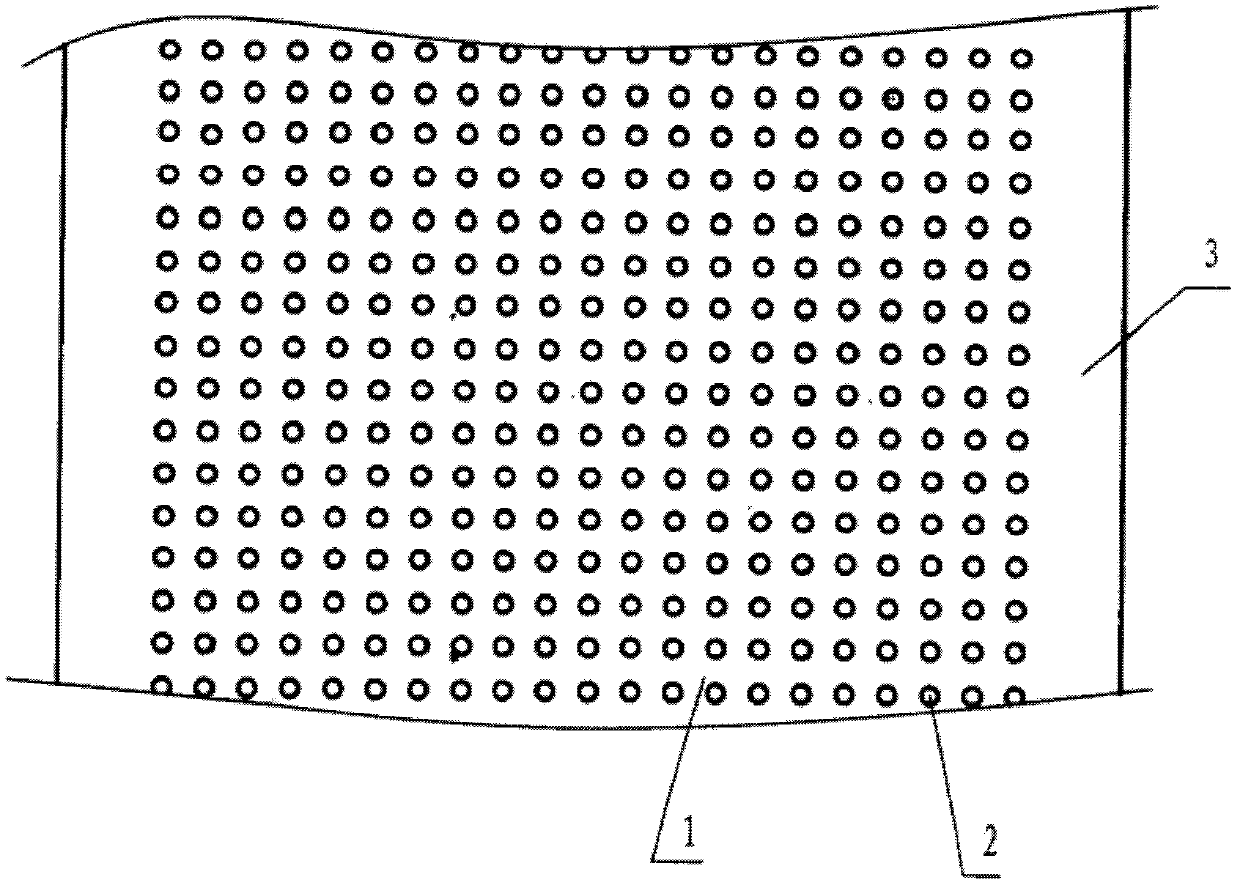

[0023] Such as figure 1 , 2 Shown, a kind of double rough geomembrane, it comprises geomembrane main body 1, and both sides of geomembrane main body 1 longitudinal sides are all provided with overlapping light edge 3, and both sides of geomembrane main body 1 are rough surface 2, and this frizzy surface It is a raised rough surface; the protrusions are convex nails or bumps; the height of the protrusions is 0.5-0.6mm. Due to the relatively high protrusion height, the friction resistance increases after laying, and the anti-slip performance is good. The anti-slip performance is much better than the existing spinning roughening and chemical foaming roughening geomembranes, especially suitable for landfills. It will not cause the slippage of the membrane. Rolling and nailing film formation can not only obtain large and wide geomembrane, the film can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com