Doped modified lithium iron phosphate and preparation method thereof

A lithium iron phosphate, modified technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of difficulty in improving high-current discharge, difficulty in LiFePO, uneven battery performance, etc. Excellent chemical properties, no three-waste emissions, and the effect of clean industrialized large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

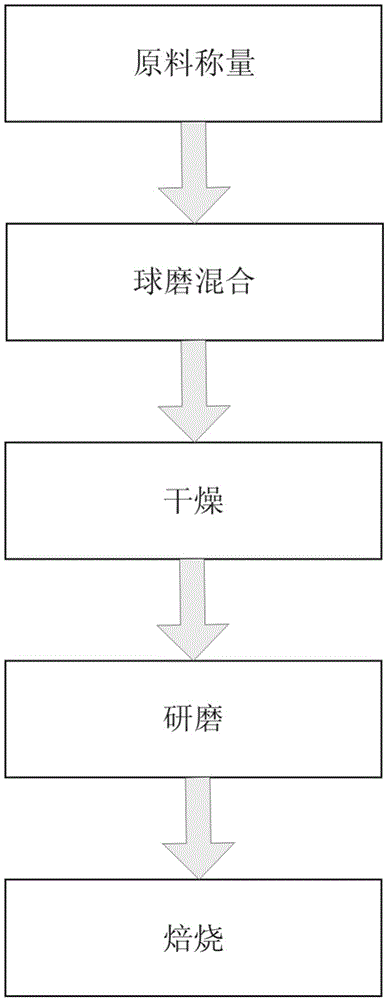

[0034] A preparation method for doping modified lithium iron phosphate, such as figure 1 process, follow the steps below:

[0035] 1. Weigh according to the raw material formula indicated in Table 1;

[0036] 2. Put the weighed raw materials in 300ml of ethanol and mix evenly, then put the mixed materials in a ball mill container, and ball mill for 36 hours;

[0037] 3. Place the ball-milled product in an air atmosphere and dry at 110°C for 10 hours. After natural cooling, grind to a particle size of 80 mesh or more to obtain a uniformly mixed high-density precursor of lithium iron phosphate;

[0038] 4. Place the precursor of lithium ferrous phosphate obtained above in a high-temperature furnace, raise the temperature to 800°C at a heating rate of 60°C / h in a nitrogen atmosphere, and roast at a constant temperature of 800°C for 20 hours, then cool naturally to 80°C Below ℃, silver-doped lithium iron phosphate powder can be obtained.

[0039] The properties and paramete...

Embodiment 2

[0041] A preparation method for doping modified lithium iron phosphate, such as figure 1 process, follow the steps below:

[0042] 1. Weigh according to the raw material formula indicated in Table 1;

[0043] 2. Put the weighed raw materials in 300ml of water and mix evenly, then put the mixed materials in a ball mill container, and ball mill for 24 hours;

[0044] 3. Place the ball-milled product in an air atmosphere and dry it at 90°C for 20 hours. After natural cooling, grind it to a particle size of 80 mesh or more to obtain a uniformly mixed high-density precursor of lithium iron phosphate;

[0045] 4. Place the precursor of lithium ferrous phosphate obtained above in a high-temperature furnace, raise the temperature to 700°C at a heating rate of 50°C / h in a nitrogen atmosphere, and roast at a constant temperature of 700°C for 20 hours, then cool naturally to 80°C Below ℃, manganese-doped lithium iron phosphate powder can be obtained.

[0046] The properties and parame...

Embodiment 3

[0048] A preparation method for doping modified lithium iron phosphate, such as figure 1 process, follow the steps below:

[0049] 1. Weigh according to the raw material formula indicated in Table 1;

[0050] 2. Put the weighed raw materials in a mixture of 300ml ether and water (the molar ratio of ether and water is 1:1) and mix evenly, then put the mixed materials in a ball mill container and mill them for 30 hours;

[0051] 3. Place the ball mill product in an air atmosphere and dry it at 100°C for 15 hours. After natural cooling, grind it to a particle size of 80 mesh or more to obtain a uniformly mixed high-density precursor of lithium iron phosphate;

[0052] 4. Place the precursor of lithium ferrous phosphate obtained above in a high-temperature furnace, in a nitrogen atmosphere, heat up to 750°C at a heating rate of 55°C / h, roast at a constant temperature of 750°C for 18 hours, and then cool naturally to 80°C Below ℃, magnesium-doped lithium iron phosphate powder can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com