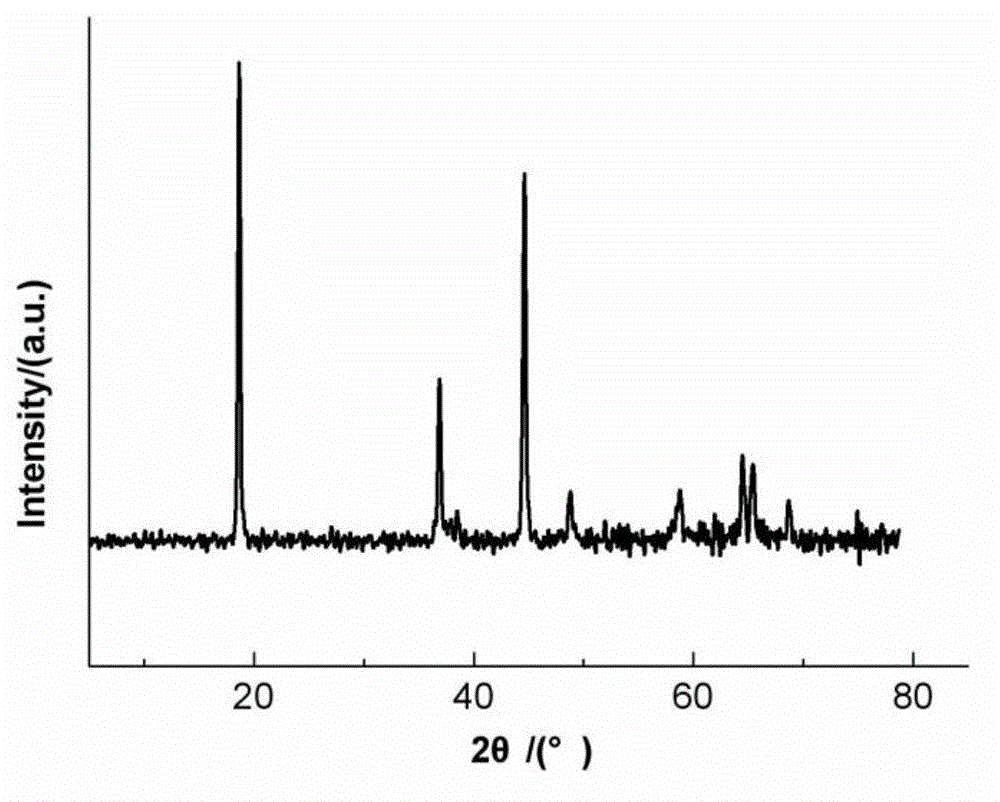

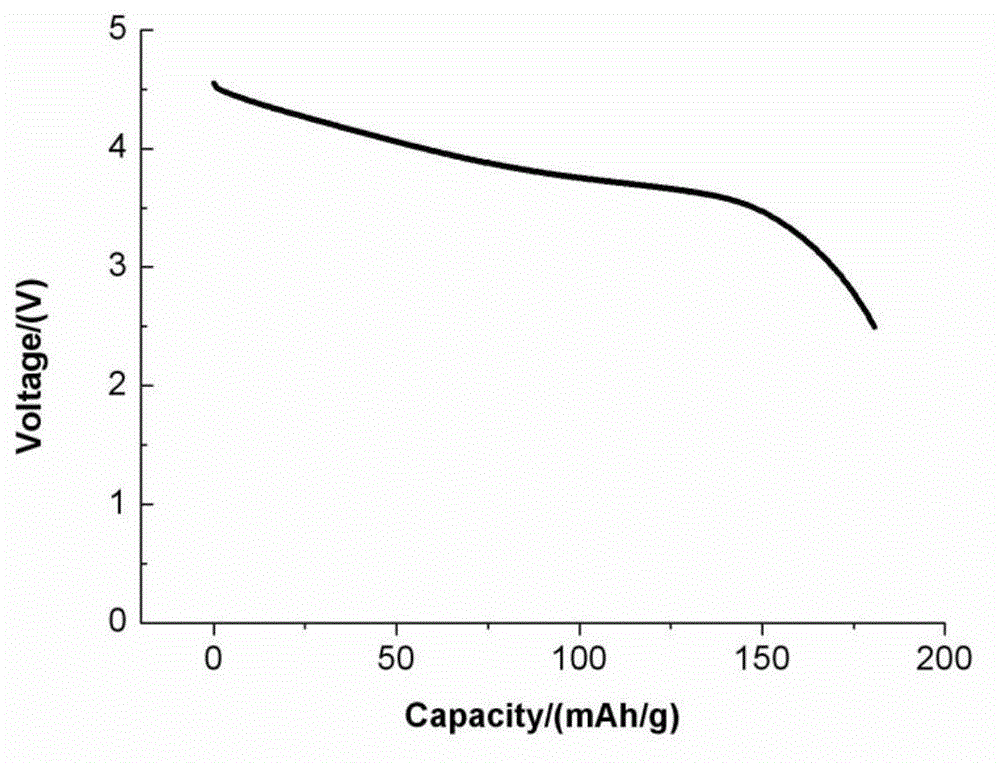

Method for preparing lithium-rich solid solution cathode material by virtue of metal reduction process

A positive electrode material and solid solution technology, which is applied in the field of preparation of lithium-rich solid solution positive electrode materials, can solve problems such as the inability to eliminate the influence of dissolved oxygen in water, and achieve excellent discharge performance, less time-consuming, and a wide range of raw material sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation process consists of the following steps:

[0037] (1) Weigh lithium hydroxide, nickel hydroxide, manganese acetate, cobalt hydroxide, and zinc powder according to the molar ratio of lithium ion, nickel ion, manganese ion, cobalt ion, and zinc powder to 1.35: 0.195: 0.506: 0.319: 0.0325 . The total weight of reactants is the total weight of lithium hydroxide, nickel hydroxide, manganese acetate, cobalt hydroxide and zinc powder. The weight ratio of the total weight of reactants to deionized water is 5:50 (equivalent to (2·(1-x)·y+4·(x+z-x·z)+3·(1-x)·k+2· (1-x) q-x-3)=0.0868)

[0038] (2) Zinc powder is mixed with deionized water, and then mixed with nickel hydroxide, manganese acetate, and cobalt hydroxide that have been weighed, mixed for 1 hour by wet grinding, and ammonia water is added to make the solution acidity pH 10, and lithium hydroxide that has been weighed is added , wet grinding and mixing for 1 hour to prepare a reaction mixture solution ...

Embodiment 2

[0041] The preparation process consists of the following steps:

[0042] (1) Weigh lithium nitrate, nickel oxalate, manganese sulfate, cobalt chloride and magnesium metal according to the molar ratio of lithium ions, nickel ions, manganese ions, cobalt ions, and metal magnesium powder is 1.15: 0.0425 : 0.354 : 0.51 : 0.0085 Powder (equivalent to (2 · (1-x) · y + 4 · (x+z-x · z) + 3 · (1-x) · k + 2 · (1-x) · q -x-3) = -0.10); the total reactant is the total weight of lithium nitrate, nickel oxalate, manganese sulfate, cobalt chloride and metal magnesium powder, and the ethanol is weighed according to the total reactant and ethanol weight ratio of 5:1.

[0043] (2) Metal magnesium powder is mixed with ethanol, then mixed into the nickel oxalate, manganese sulfate and cobalt chloride taken by weighing, wet milling and mixing for 15 hours, adding ammonia water to make the solution acidity pH 13.5, adding lithium nitrate taken by weighing, wet milling Mix for 15 hours to prepare a...

Embodiment 3

[0046] The preparation process consists of the following steps:

[0047] (1) Weigh lithium iodide, nickel nitrate, manganese oxalate, cobalt oxalate, and aluminum powder according to the molar ratio of lithium ions, nickel ions, manganese ions, cobalt ions, and metal aluminum powder to 1.6 : 0.18: 0.77 : 0.02 : 0.04, respectively. The total weight of the reactant is the total weight of lithium iodide, nickel nitrate, manganese oxalate, cobalt oxalate and metal aluminum powder, according to the total weight of the reactant and methanol weight ratio is 1:1 weighing methanol (equivalent to (2.(1 -x) y + 4 (x+z-x z) + 3 (1-x) k + 2 (1-x) q -x-3)=-0.02).

[0048] (2) Mix the metal aluminum powder with methanol, then mix the weighed nickel nitrate, manganese oxalate and cobalt oxalate, wet mill and mix for 1 hour, add ammonia water to make the solution acidity pH 10, add the weighed lithium iodide, wet mill Mix for 1 hour to prepare a reaction mixture solution containing precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com