Acrylamide graft copolymer oil-displacing agent and preparation method thereof

A graft copolymer and acrylamide technology, which is applied in the field of acrylamide graft copolymer oil displacement agent and preparation, can solve problems such as failure to achieve engineering construction, sudden change of solution properties, etc. water soluble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of AM / AA / APEG / KGM graft copolymer

[0029]According to the ratio of raw materials in Table 1, take KGM in a 150mL three-necked flask, add 20ml of deionized water, and stir at a constant temperature of 30°C for 30min to allow it to fully swell. Then add AM, AA and APEG in sequence, then use 25% NaOH to adjust the pH to the specified value, make the system into a 25% aqueous solution, pass nitrogen gas for 10 minutes, raise the temperature to 40°C and keep the temperature for 20 minutes, add the initiator cerium ammonium nitrate, and pass Nitrogen for 10 minutes, after reacting at 40°C for 8 hours, a light yellow transparent viscous liquid was obtained. Slowly pour the product into a beaker filled with absolute ethanol and keep stirring to obtain a white precipitated floc, which is soaked for 5 hours. The unreacted konjac glucomannan, graft copolymer and self-polymer were all insoluble in absolute ethanol, filtered under reduced pressure, an...

Embodiment 2

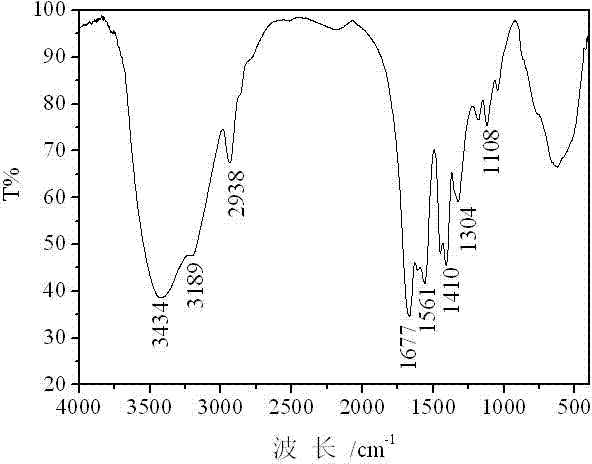

[0032] Embodiment 2: AM / AA / APEG / KGM graft copolymer structure characterization

[0033] The infrared spectrogram of the graft copolymer AM / AA / APEG / KGM synthesized by embodiment 1 is as follows figure 1 shown. The figure shows that the infrared spectrum of the copolymer is at 3434cm -1 There is a strong absorption peak at , which is the stretching vibration of O-H in the hydroxyl group, and the peak intensity is relatively strong, indicating the existence of polyhydroxyl structure; the stretching vibration of N-H is at 3300cm -1 Left and right, because the hydroxyl absorption peak is very strong, it covers the N-H absorption vibration peak, so the N-H absorption peak does not appear; at 2938cm -1 The strong absorption peak at -CH 2 - stretching vibration at 1677cm -1 It is the stretching vibration of -C=O, which proves that there is an amide structure in the polymer molecule, and the product is an AM / AA / APEG / KGM graft copolymer.

Embodiment 3

[0034] Embodiment 3: the mensuration of AM / AA / APEG / KGM graft copolymer relative molecular weight

[0035] With reference to GB / T 12005.10-92 "Polyacrylamide Molecular Weight Determination Viscosity Method", the tetrapolymer prepared in Example 2 was used to prepare a 0.1wt% solution, and at 30±0.1°C, it was measured by stepwise dilution method. The intrinsic viscosity of the branch copolymer was 1129.3 mL / g. Using empirical formula M=802[η] 1.25 , M is the viscosity-average relative molecular mass, [η] is the intrinsic viscosity, 802, and 1.25 are empirical constants. The calculated viscosity-average relative molecular weight of the polymer is about 5.3×10 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com