Double-internal circulating water treatment device capable of combining photocatalysis and aerobe, and working method thereof

An aerobic biological and water processor technology, applied in biological water/sewage treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve the technical solutions not mentioned and involved in the treatment of organic matter in wastewater, increase the treatment safety factor , increase production costs and other issues, to achieve the effect of improving water treatment effect, reducing maintenance and maintenance costs, and easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the titanium dioxide light particles comprises the following steps:

[0055] (1) Using a magnetic constant temperature stirrer, add analytically pure butyl titanate and analytically pure glacial acetic acid to absolute ethanol in sequence at 25°C, and stir for 15-20 minutes to obtain a uniform and transparent light yellow solution; the titanic acid The parts by volume of butyl ester, glacial acetic acid and dehydrated alcohol are respectively:

[0056] Butyl titanate: 5 parts;

[0057] Glacial acetic acid: 1 part;

[0058] Anhydrous ethanol: 15 parts;

[0059] (2) Continue to stir, add 27-28% HNO by volume of the light yellow solution obtained in step (1) 3 - ethanol solution; the HNO 3 -The ethanol solution comprises the following raw materials in parts by volume ratio:

[0060] Concentration of 65-68wt% HNO 3 Solution: 1 part;

[0061] Anhydrous ethanol: 20 parts;

[0062] Deionized water: 2 parts;

[0063] The HNO 3 -The preparatio...

Embodiment 1

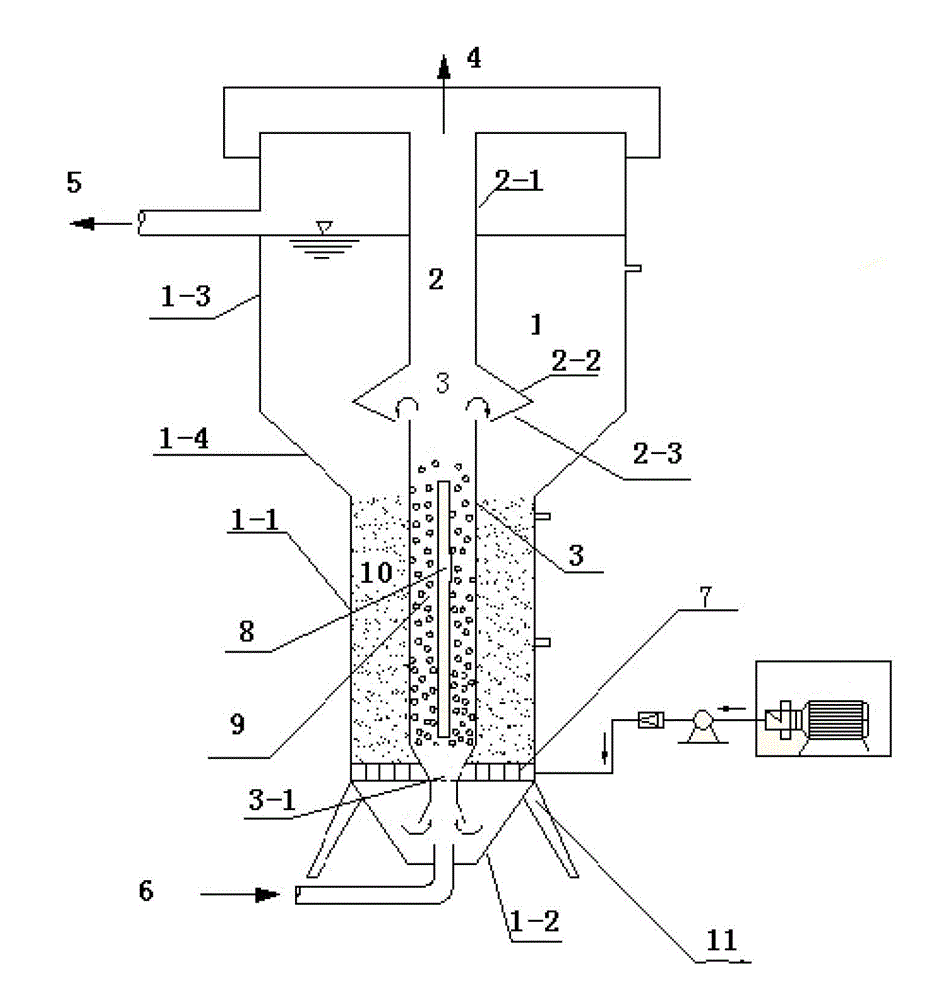

[0071] A double internal circulation water processor combining photocatalysis and aerobic organisms, including a reaction cylinder 1, a three-phase separator 2 and a stripping cylinder 3 are arranged at the axial position of the reaction cylinder from top to bottom, and at the top of the reaction cylinder 1 An air outlet pipe 4 is provided to be connected to the three-phase separator 2, a water outlet 5 is provided on the upper wall of the reaction cylinder 1, and a water inlet pipe 6 and the bottom end of the stripping cylinder 3 are arranged at the bottom of the reaction cylinder 1 In contrast, an aeration disc 7 is arranged around the bottom of the stripping cylinder 3, and the aeration disc 7 has micropores for the sewage to flow down. The aeration disc 7 divides the reaction cylinder 1 into a settling zone 1-1 and a reflux zone 1- 2. Two parts; an ultraviolet light source 8 and titanium dioxide light particles 9 are arranged in the airlift cylinder 3; aerobic activated slu...

Embodiment 2

[0075] A kind of waste water method that utilizes water processor as described in embodiment 1 to process certain textile factory in Shandong area, comprises steps as follows:

[0076] (1) Turn on the ultraviolet light source 8, and pump the sewage into the airlift cylinder 3 along the water inlet pipe;

[0077] (2) The sewage is uniformly mixed with the light titanium dioxide particles 9 in the airlift drum 3, and under the irradiation of the ultraviolet light source and the catalysis of titanium dioxide, the refractory organic matter in the sewage is degraded into a biodegradable compound; the sewage rises To the three-phase separator: the gas is discharged along the gas outlet pipe; the light particles of titanium dioxide are blocked back into the stripper 3 by the three-phase separator; the sewage is returned to the settling zone 1-1 of the reaction cylinder;

[0078] (3) The sewage is aerated in the settlement zone 1-1, fully mixed with the aerobic activated sludge 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com