Method for machining micropores on glass sealed alloy

A microporous and alloy technology, used in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of difficult chip removal, high hardness of glass sealing alloys, sticking to knives, etc., to prolong service life and improve production efficiency. , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

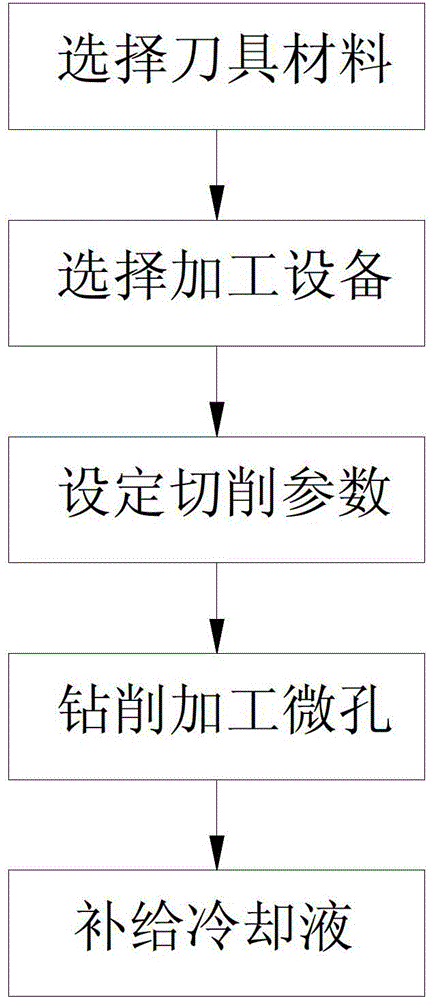

[0018] Such as figure 1 As shown, a method for processing micropores on glass sealing alloy according to the present invention mainly realizes drilling and processing micropores on glass sealing alloy through the following steps:

[0019] (1) Select tool material: Tungsten-cobalt cemented carbide is used as the tool material. After a variety of comparative processing, the practical tungsten-cobalt cemented carbide is more durable;

[0020] (2) Selection of processing equipment: The processing equipment is a small precision lathe CM6125, and a cam adjustment mechanism is installed on the feeding device of the small precision lathe CM6125, so that it can realize the function of automatic knife retraction and knife feeding; the feed adjustment The mechanism can realize the function that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com