Ceramisite concrete self-heat-preservation masonry structure

A technology of ceramsite concrete and masonry structure, which is applied in the direction of building materials, etc., can solve the problems of low production cost, etc., and achieve the effect of eliminating cold and heat bridges, good heat insulation effect, and poor heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

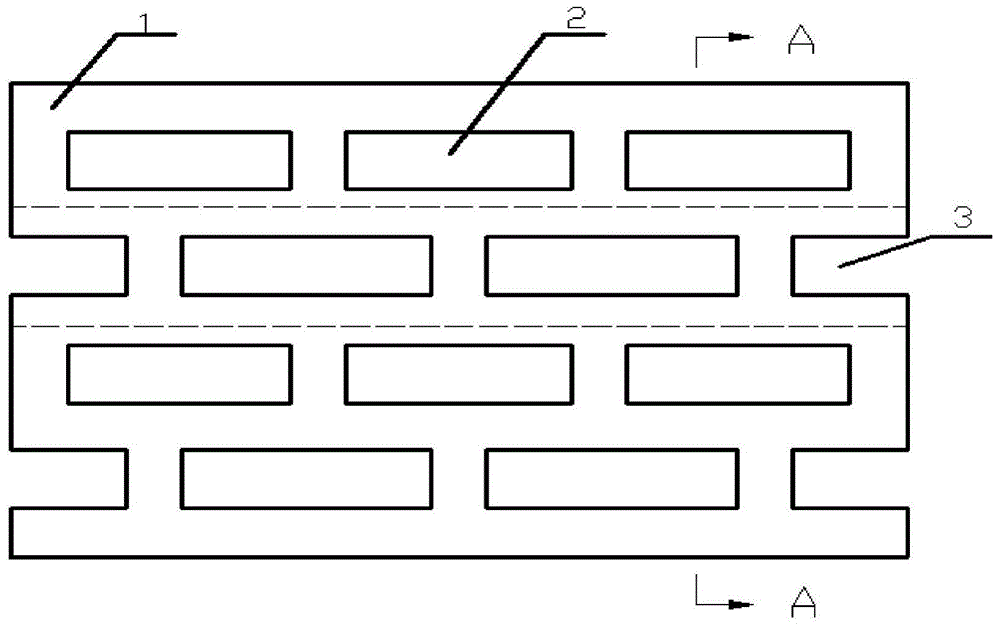

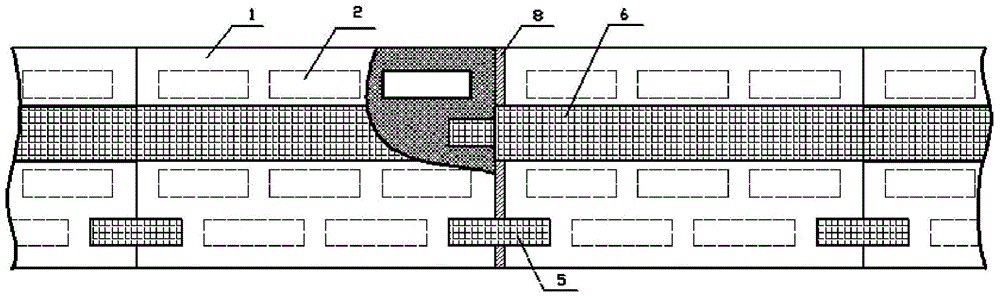

[0023] Such as figure 1 As shown, the ex-factory shape of the block in the present invention only includes the self-insulating block 1 and the holes 2 scattered thereon. The presence of the slots 2 allows the ribs to be staggered, thus reducing their thermal and thermal bridge effects. The side opening grooves 3 at the left and right ends are then used for inserting the foamed plastic heat insulation material 5 when docking masonry.

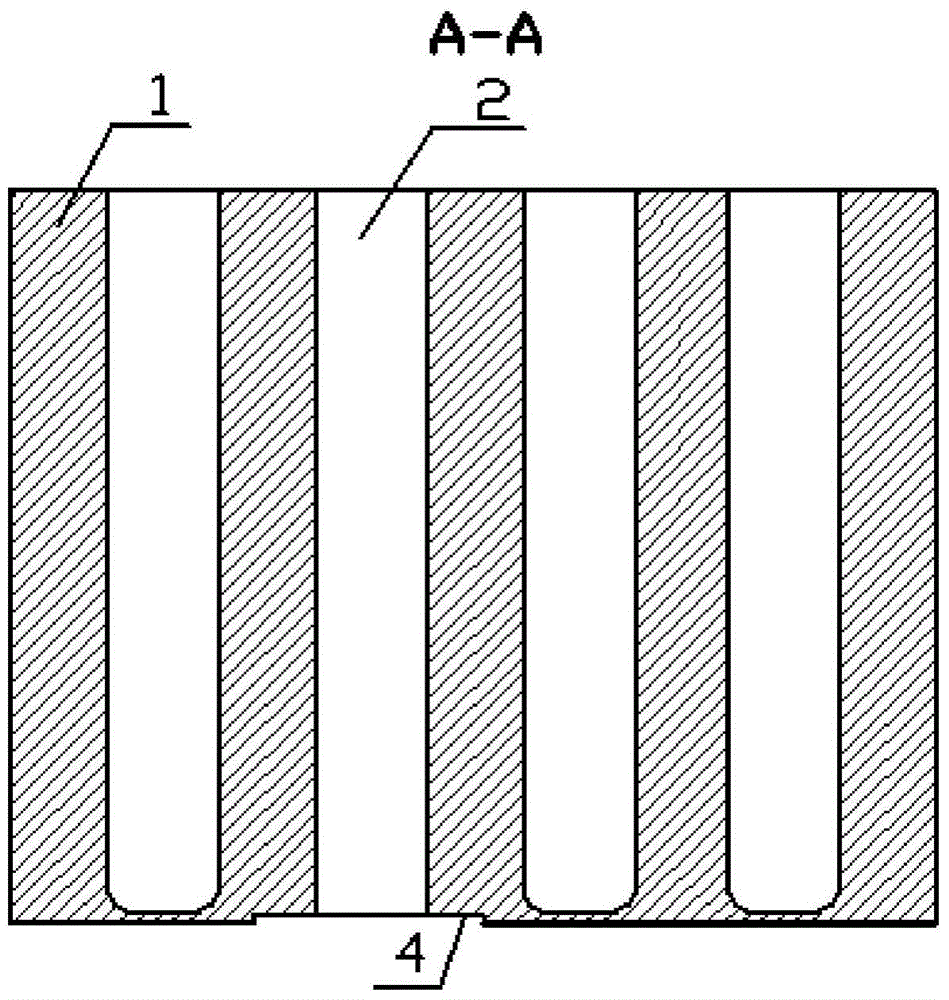

[0024] In the embodiment of the present invention, the matrix is ceramsite concrete with low thermal conductivity, and 3 to 4 rows of hole slots are evenly distributed on the cuboid-shaped block, and different hole lengths are designed between the hole slots of two adjacent rows, so that The ribs are staggered to increase the thermal resistance of the block. The bottom of the block is sealed (bottom up during masonry) to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com