Programmable strong hub cap ring cutter

A cutting machine and wheel hub technology, which is applied in the field of cutting equipment for gravity casting automobile wheel hub blanks, can solve the problems of increasing costs, not being able to transport waste out of the machine tool, and not ensuring the safety of personnel, so as to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

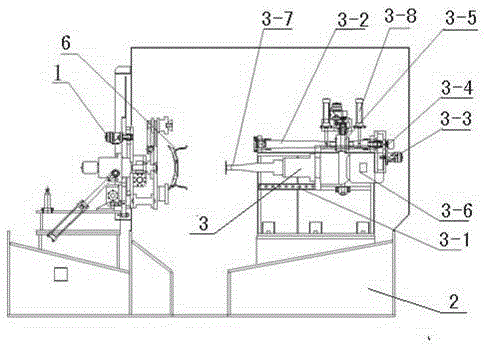

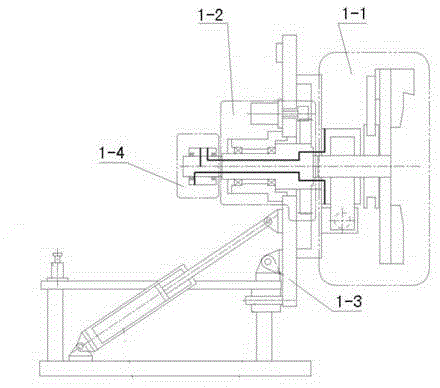

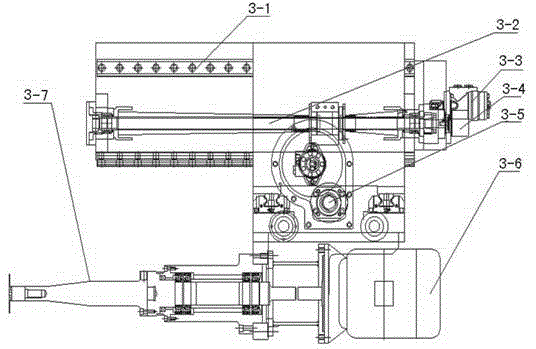

[0017] by figure 1 It is known that a programmable powerful hub ring cutting machine is composed of a clamp part 1, a bed 2, a small knife part 3, a big knife part 4, and a control part 5. The bed 2 is equipped with a spindle, a clamp part 1 and a control part. 5. The main shaft is equipped with a small knife part 3 and a big knife part 4. After the clamp part 1 automatically clamps the centering hub blank 6, it automatically turns into the bed 2 and rotates quickly. The small knife part 3 starts to cut the center riser of the hub blank 6. While the small knife is cutting, the big knife part 4 runs to the starting point. After cutting, the knife returns to a safe position. The fixture stops rotating and starts 120o positioning. The big knife starts to cut the remaining burrs of the wheel hub blank 6. The fixture position is changed several times to complete the entire cutting. In the safe position, the clamp is automatically turned out of the machine tool, and the wheel hub blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com