Acoustic deashing and dedusting device

A sonic cleaning and dust removal technology, which is applied in electrode cleaning, chemical instruments and methods, and separation of dispersed particles, can solve the problems that dust cannot be completely removed, operating costs increase, and dust removal efficiency is low, so as to save manpower and reduce Maintenance cost, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

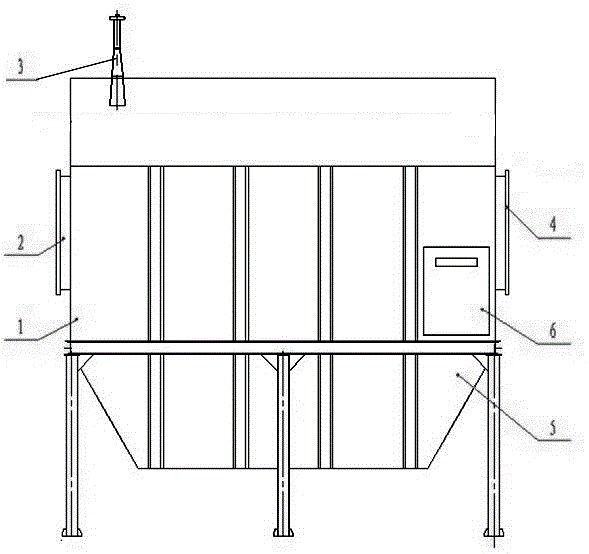

[0025] Embodiment 1: A bag filter for sonic cleaning, comprising: a box body 1 for support and protection; an air inlet 2 arranged on one side of the box body 1 and an air outlet 4 on the opposite side, respectively for Pass in dusty gas and discharge clean gas. The air inlet 2 controls the filtering wind speed below 1.0m / min; the air outlet 4 is connected to a negative pressure fan to maintain a negative pressure environment in the box body 1. The ash hopper 5 is arranged under the box body 1 to receive the dust collected by the dust collector, and a column is also arranged under the ash hopper 5 to play a supporting role.

[0026] It also includes an acoustic wave generator 3 arranged on the box body 1 for cleaning the dust deposited on the surface of the filter bag inside the box body 1 . Described acoustic wave generator 3 is arranged on the side wall of casing 1, and the frequency setting of acoustic wave generator and the size of casing 1 need to satisfy following condi...

Embodiment 2

[0033] Embodiment 2: a kind of electric precipitator of sonic cleaning, as figure 2 As shown, it includes: a box body 1 for support and protection; an air inlet 2 arranged on one side of the box body 1 and an air outlet 4 on the opposite side, which are respectively used for introducing dusty gas and discharging clean gas. The air inlet 2 controls the filtering wind speed below 1.0m / min; the air outlet 4 is connected to a negative pressure fan to maintain a negative pressure environment in the box body 1. The ash hopper 5 is arranged under the box body 1 to receive the dust collected by the dust collector, and a column is also arranged under the ash hopper 5 to play a supporting role.

[0034] It also includes an acoustic wave generator 3 arranged on the box body 1, which is used to clean the dust deposited on the surface of the inner pole plate and polar line of the box body 1. The sound wave generator 3 is arranged on the top of the box body 1, and the frequency setting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com