A high performance frequency selective radome

A technology of frequency selection and radome, applied in the field of stealth, can solve problems such as difficult FSS engineering, difficult process, complex structure, etc., and achieve the effects of small passband insertion loss, reduced process difficulty, and large process tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings.

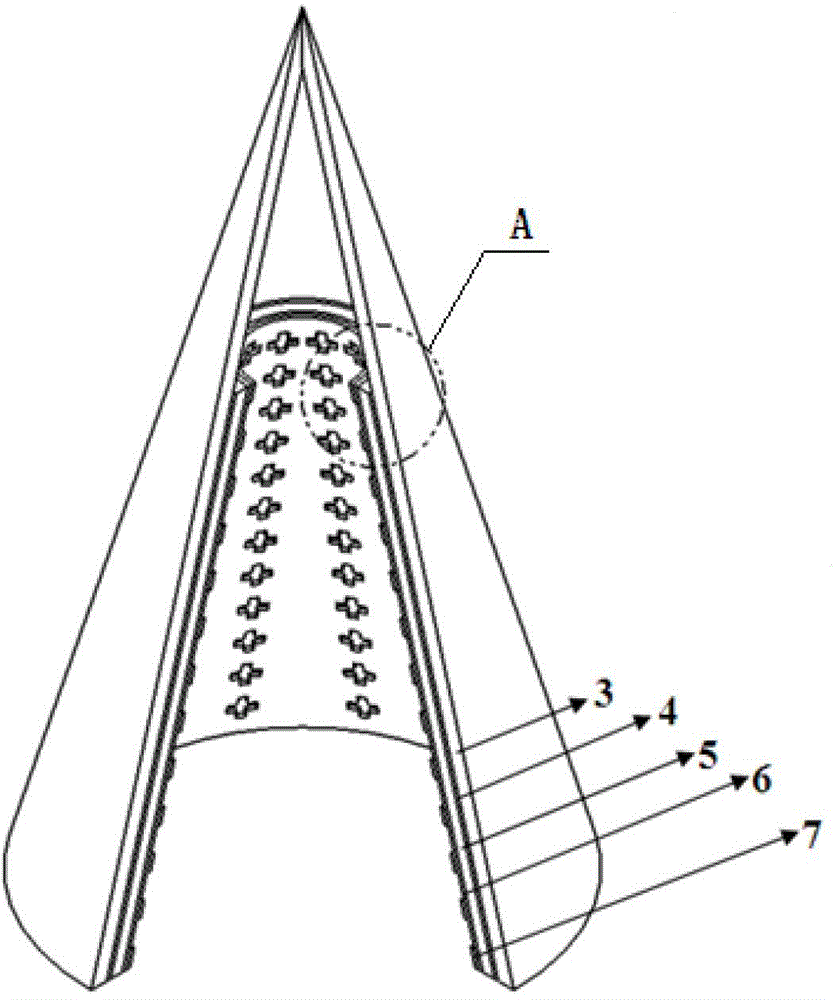

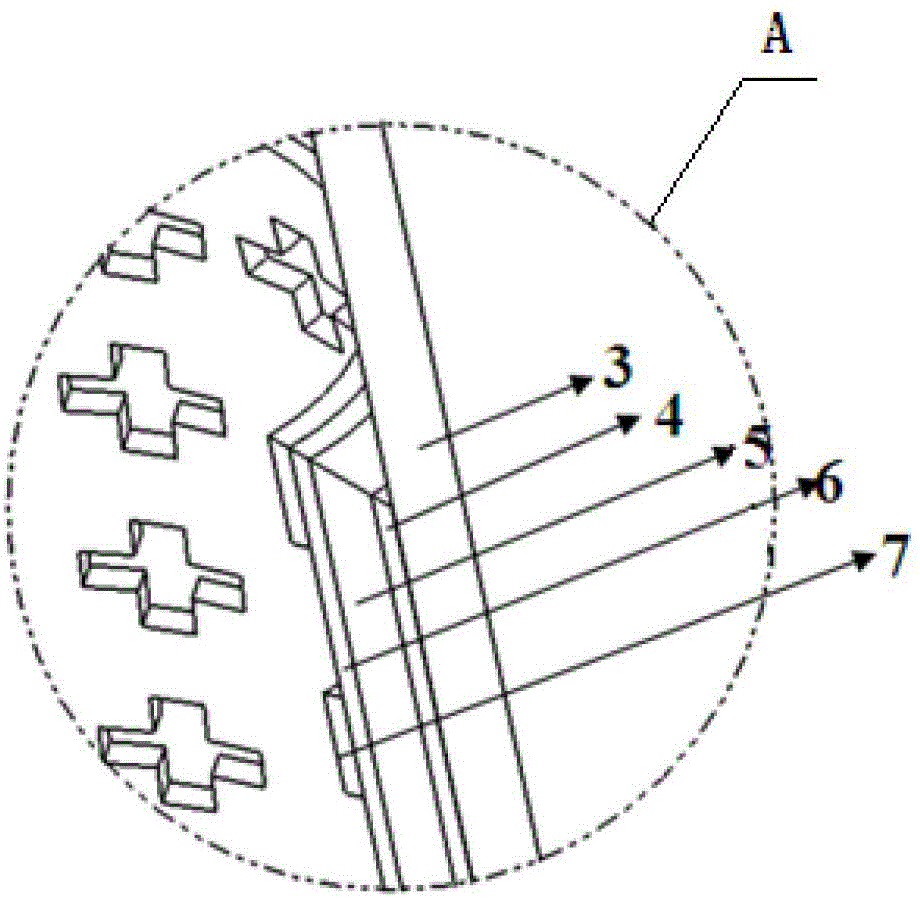

[0017] like figure 2 and image 3 As shown in the figure, the high-performance frequency selective radome used for stealth of flying weapons is to use a certain process to combine the first adhesive medium layer 4, the ultra-low dielectric constant medium layer 5, the second adhesive medium layer 6 and the flexible FSS film Layer 7 is formed according to the size of the inner surface of the original radome 3, and is laminated to form the FSS liner, and then the FSS liner is laminated on the inner surface of the original radar 3 by a certain process. An adhesive medium layer 4 , an ultra-low dielectric constant medium layer 5 , a second adhesive medium layer 6 and a flexible FSS film layer 7 are formed and formed by one-time lamination.

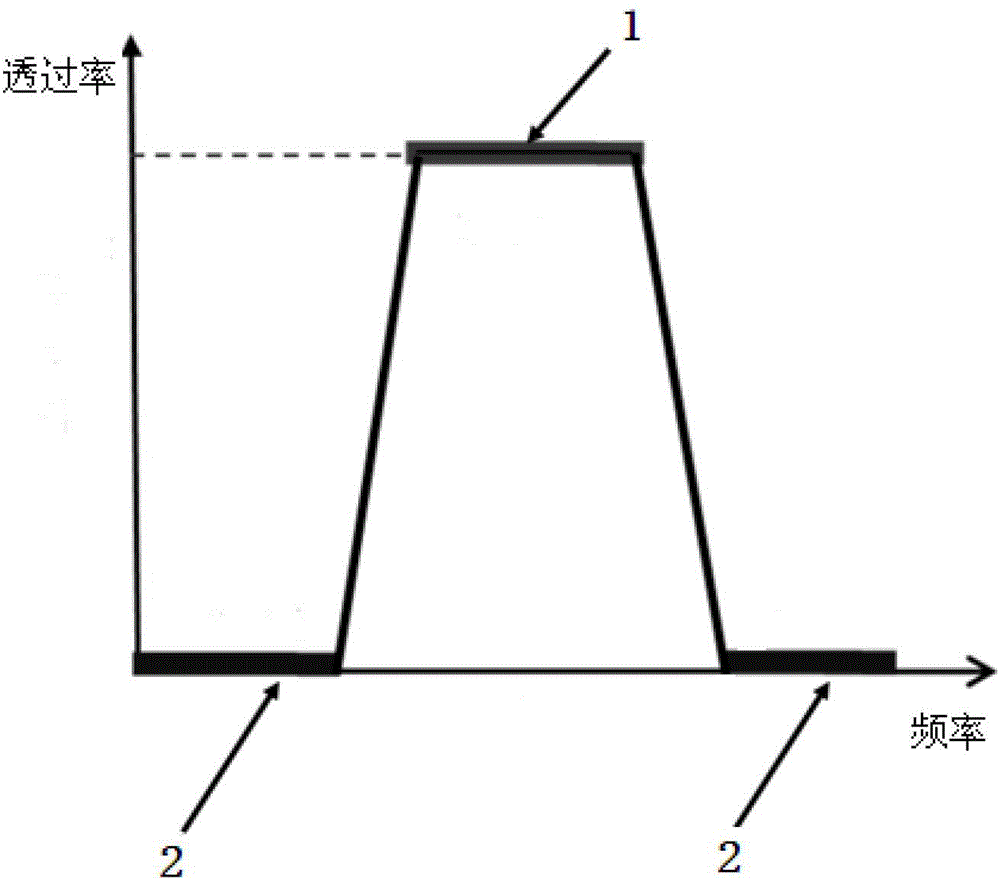

[0018] FSS array design is based on specific technical indicators such as passband and stopband transmittance, bandwidth, etc., an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com