Electric vacuum pump for motor vehicle

A vacuum pump and inlet connection technology, applied in the direction of machine/engine, rotary piston type/swing piston type pump components, pumps, etc., can solve the problems of high labor cost, large material cost, long cycle, etc., to reduce the use and shorten the time, the effect of avoiding overheating of the vacuum pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

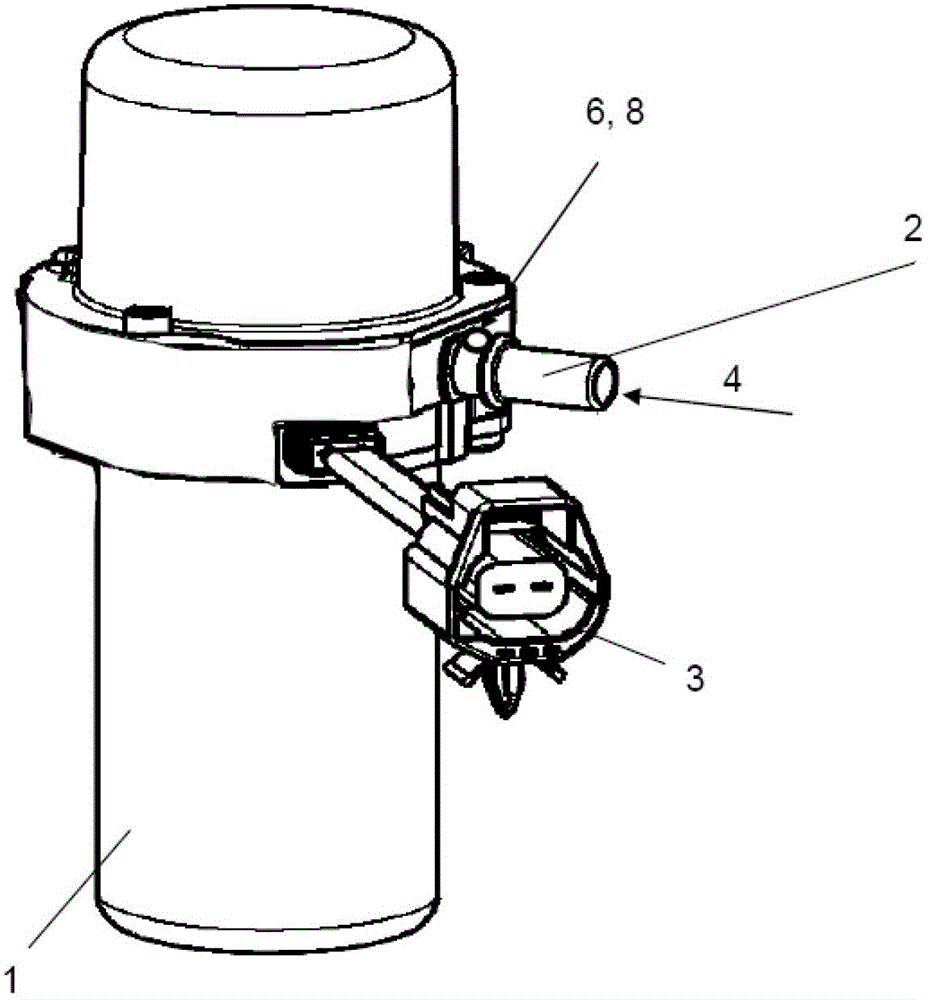

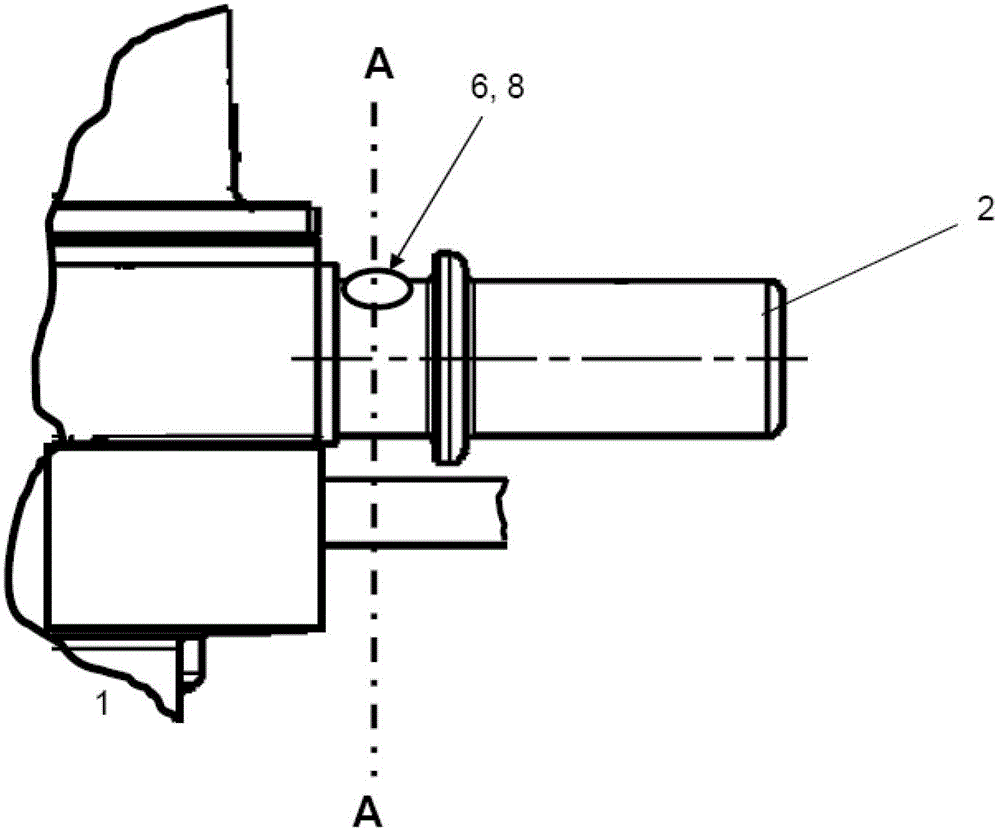

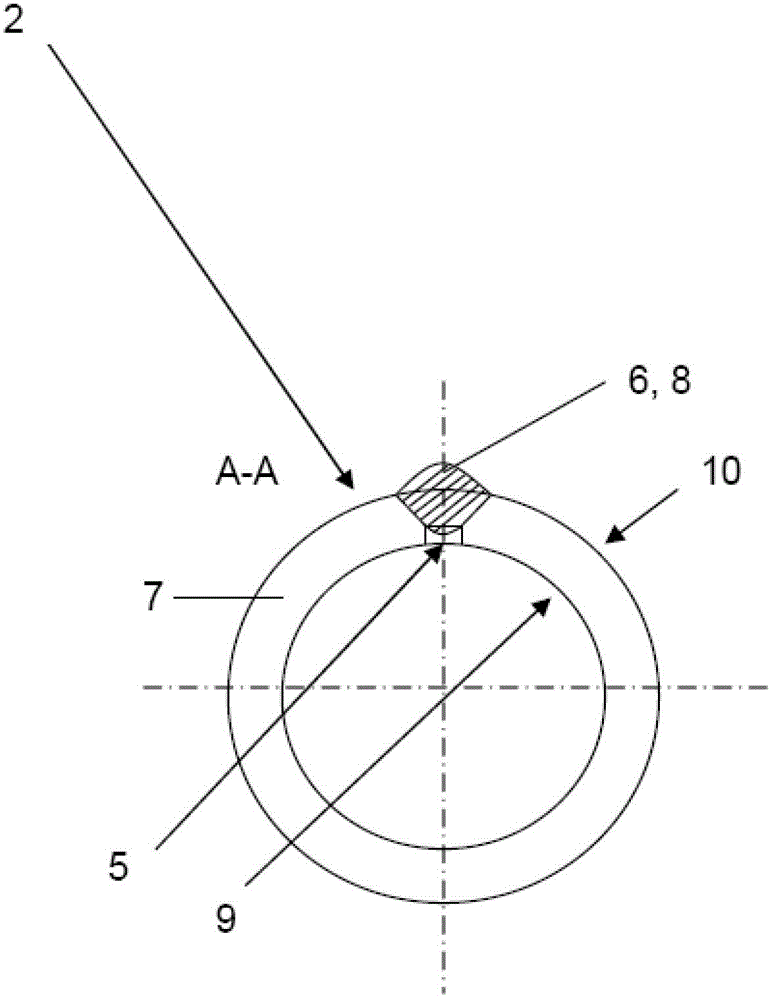

[0024] figure 1 Represents a vacuum pump 1, specifically, a vane vacuum pump 1, whose inlet connector 2 is connected to a unit (not shown in the figure) that will generate negative pressure through a connecting pipeline (not shown in the figure), the vacuum pump 1 A check valve (not shown in the figure) is provided between the vacuum pump 1 and the unit, and the vacuum pump 1 is controlled by a monitoring unit (not shown in the figure).

[0025] In the present example, the vacuum pump 1 is driven electrically, for which purpose a corresponding electrical connector 3 is provided. The monitoring unit can be connected with the electrical connector. The monitoring unit causes the vacuum pump 1 to switch on and off and thus enter into an operating state.

[0026] For example, when the vacuum pump 1 is in operation, the unit that will generate negative pressure is the brake servo unit.

[0027] When the vacuum pump 1 has been in operation, it sucks the medium from the unit into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com