Photohardening resin composition and application thereof

A resin composition and photocuring technology, applied in the field of photocurable resin compositions, can solve the problems of small volume shrinkage, outgassing quality, poor curing rate, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

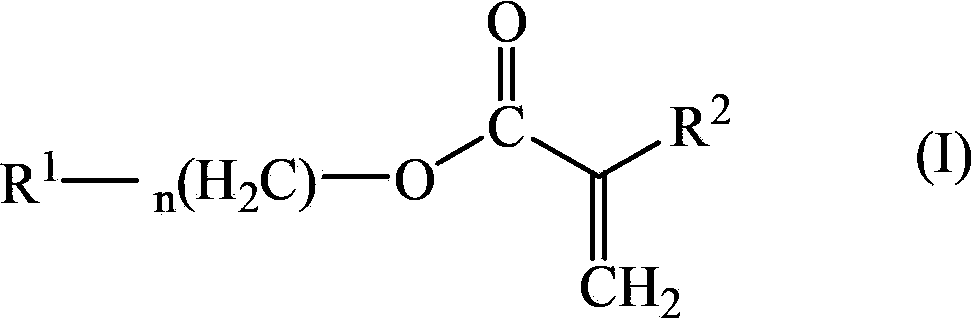

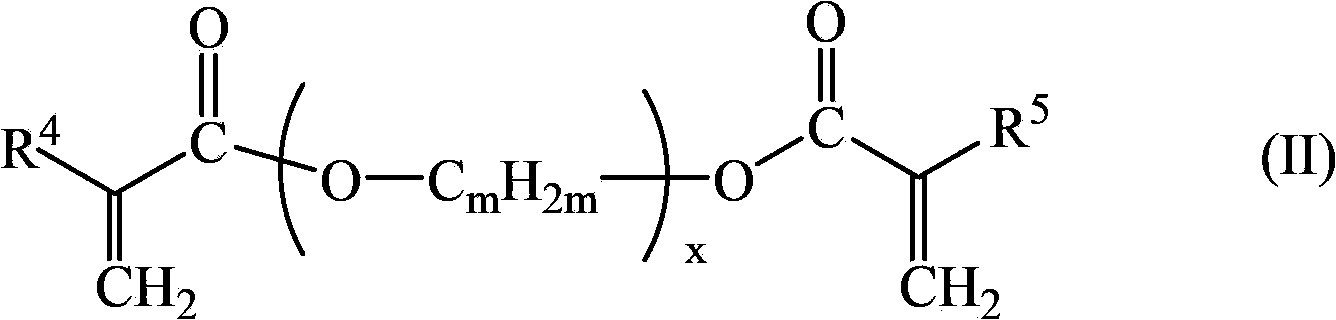

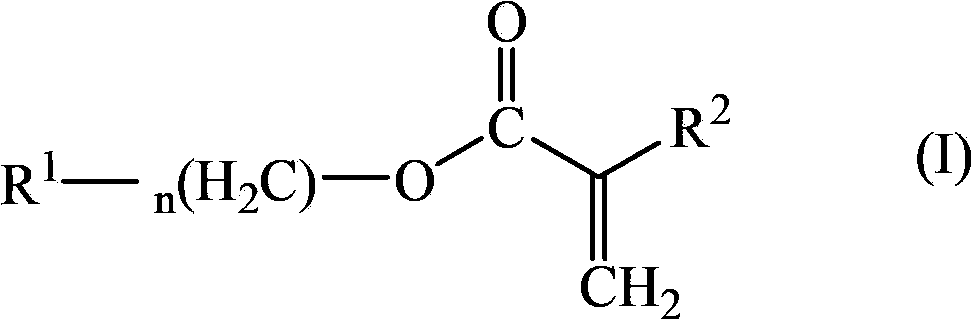

Method used

Image

Examples

Embodiment 1

[0059] Preparation of photocurable resin composition

[0060] The photocurable resin composition of Example 1 includes (A) 100 parts by weight of olefin-containing oligomer UC203, (B) monomers containing at least one acrylate group including dicyclopentadienyl ethoxy acrylate 22.2 and 12.3 parts by weight of methyl triethylene glycol acrylate, (C) photoinitiator including 3.4 parts by weight of TPO and 6.8 parts by weight of I184, and (D) 196.6 parts by weight of softener polybutadiene. After mixing the above components uniformly, the photocurable resin composition is obtained.

[0061] hard programming

[0062] The photocurable resin composition was irradiated with a low-pressure mercury lamp contained in an exposure machine (purchased from USHIO Company, model USH-500BYI), wherein the ultraviolet light wavelength band was 365nm, and the exposure intensity was 30mW / cm 2 And the irradiation dose is 5000mJ / cm 2 , to cure the resin composition.

[0063] Curing ratio analysis...

Embodiment 2~4 and comparative example 1~2

[0075] The preparation method of the photocurable resin composition of Examples 2~4 and Comparative Examples 1~2 is the same as that of Example 1, the difference is that each Example and Comparative Example use different compounds containing at least one acrylate group monomer Kind, the chemicals used in Examples 2~4 and Comparative Examples 1~2 and consumption are recorded in Table 1.

[0076] The photocurable resin compositions of Examples 2-4 and Comparative Examples 1-2 were respectively subjected to curing rate analysis. The analysis and calculation methods were the same as those of Example 1, and the calculation results are listed in Table 1.

[0077] Table 1

[0078]

[0079]As shown in Table 1, the differences in the components of Examples 1-4 and Comparative Examples 1-2 mainly lie in the types of monomers containing at least one acrylate group. From the test results, it can be clearly known that Examples 1-4 can obtain a curing rate higher than 90% and a normal a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com