Hyperbranched macromolecule dispersing agent for dispersing dyes and preparation method thereof

A technology of hyperbranched macromolecules and disperse dyes, applied in the field of fine chemical industry, can solve the problems of single variety of dispersants and poor dispersion stability, and achieve the effect of excellent solubilization and dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

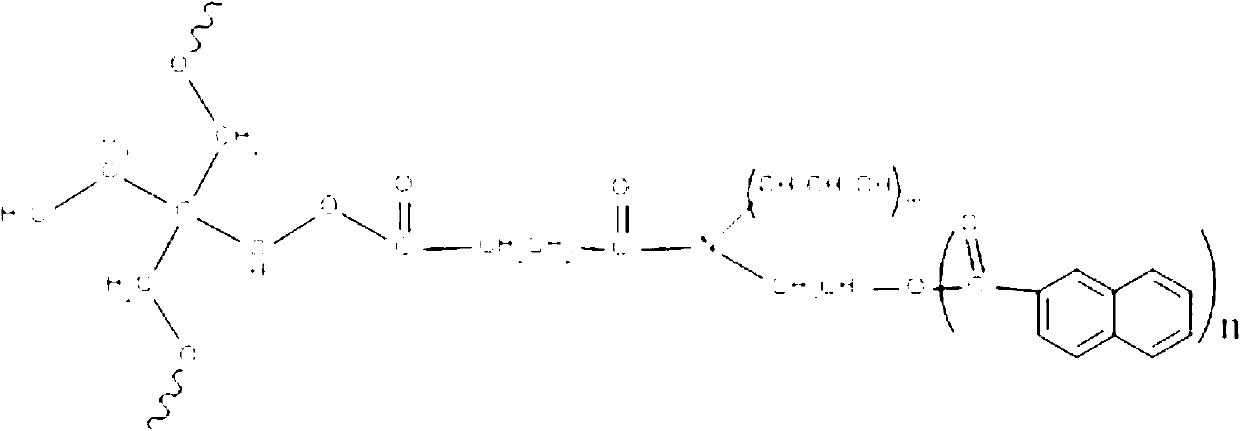

preparation example Construction

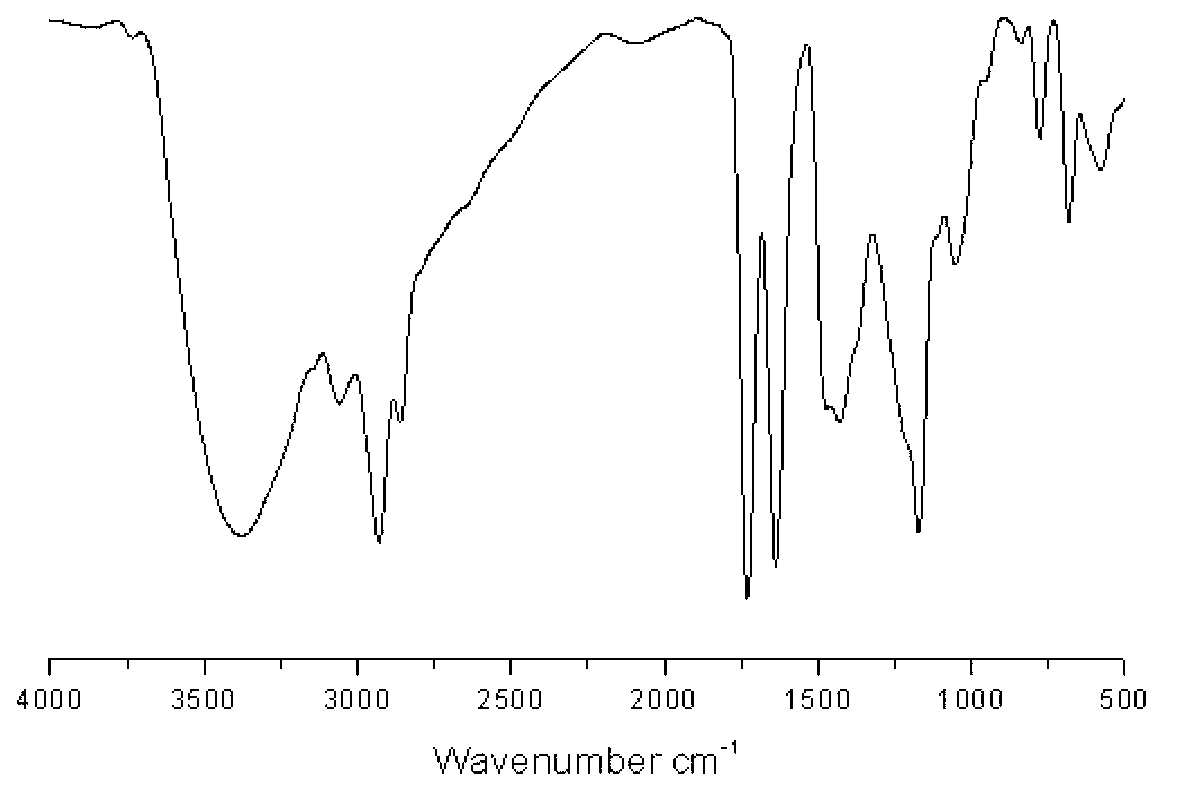

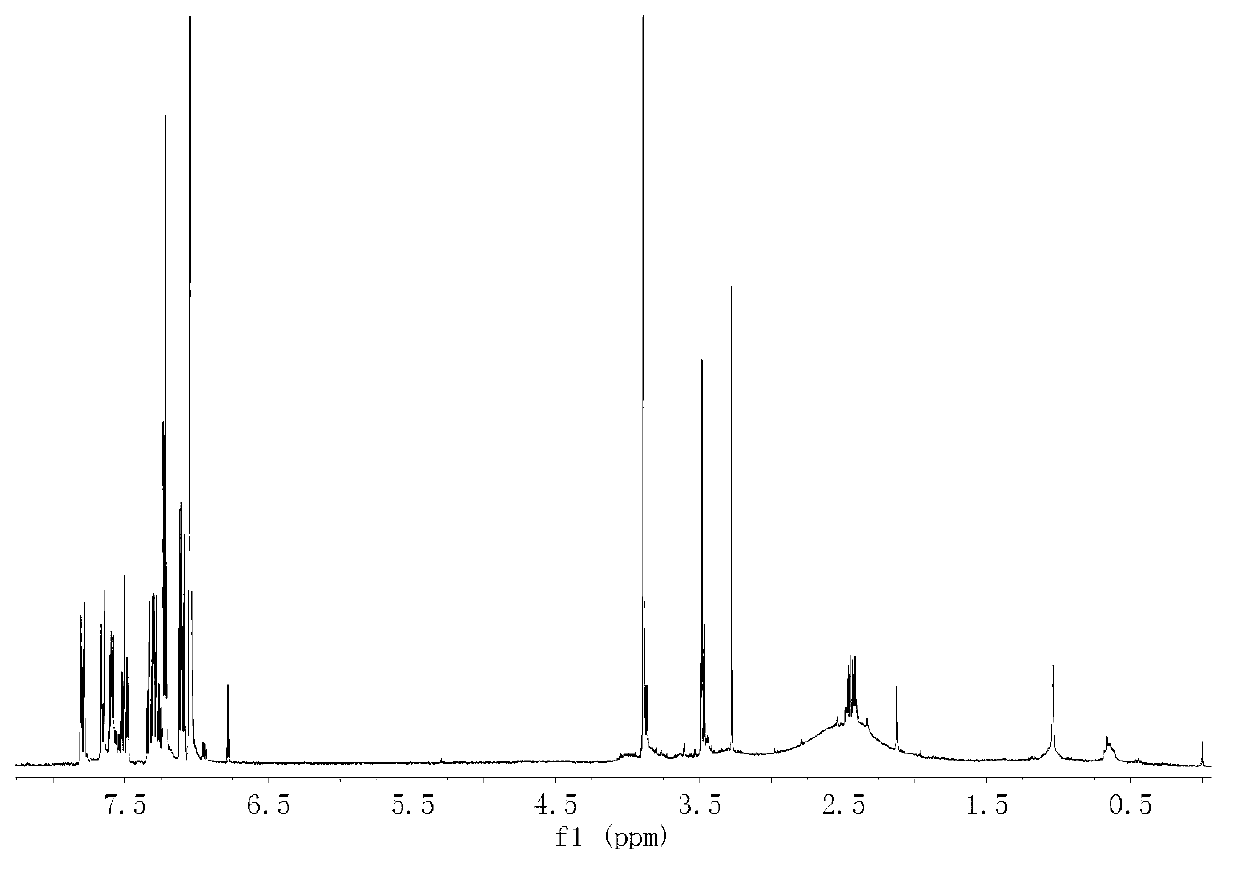

[0022] Its preparation method is: it is prepared by reacting a hyperbranched polymer solution and an aromatic naphthalene acid solution, and specifically includes the following steps:

[0023] Step 1. get hyperbranched polymer and be dissolved in solvent, make hyperbranched polymer solution through fully dissolving, get aromatic naphthoic acid and dissolve in solvent, make naphthoic acid solution through fully dissolving; Hyperbranched polymer and solvent The mass ratio is 1:1-5, and the mass ratio of the aromatic naphthoic acid to the solvent is 1:1-5.

[0024] Step 2. Put the hyperbranched polymer solution in the reaction vessel, add the catalyst, heat to 60-180°C under stirring, then add the naphthalene acid solution dropwise for reaction, cool down after the reaction, evaporate and remove the solvent to obtain the crude product; cooling temperature The temperature is 20~50℃, and the cooling time is 1~5h.

[0025] Step 3, adding the obtained crude product into a solvent to...

Embodiment 1

[0033] Embodiment 1: 0.1mol hydroxyl-terminated hyperbranched polyester is dissolved in 30ml toluene to make a hydroxyl-terminated hyperbranched polyester solution, and 0.02mol2-naphthoic acid is dissolved in 20ml N,N-dimethylformamide to prepare into a 2-naphthoic acid solution; the hydroxyl-terminated hyperbranched polyester solution is added to a four-necked flask, and 2% p-toluenesulfonic acid (based on the quality of the hyperbranched polyester) is added, heated to 120°C, and 2- Naphthoic acid solution, stirred, reacted for 4 hours, cooled after the reaction, the cooling temperature was 35°C, cooled for 3 hours, and the solvent was removed by rotary evaporation, and the crude product was obtained after evaporation to dryness, then the crude product was dissolved in chloroform, and the solution was added dropwise to In water, the chloroform layer was rotary evaporated to remove the solvent to obtain a light yellow solid, which was vacuum-dried for 18 hours at a vacuum of 20...

Embodiment 5

[0039] Embodiment 5, 0.1mol amino-terminated hyperbranched polyamide is dissolved in 50ml toluene to make a solution, 0.05mol 6-hydroxyl-2-naphthoic acid is dissolved in 30ml pyridine to make a solution, and the amino-terminated hyperbranched polyamide solution is added Add 0.5% butyl titanate (according to the mass of hyperbranched polyamide) into the four-necked flask, heat to 100°C, add 6-hydroxy-2-naphthoic acid solution dropwise, and stir for 6 hours. After cooling, the cooling temperature was 30°C, cooled for 2 hours, and the solvent was removed by rotary evaporation to obtain the crude product, then the crude product was dissolved in dichloromethane, the solution was added dropwise to ether to precipitate, the dichloromethane layer was separated and removed by rotary evaporation The solvent was used to obtain a light yellow solid, and the vacuum degree was 10KPa, and the hyperbranched polymer dispersant was obtained by vacuum drying for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com