Hot shaping method of large-specification titanium plate

A large-scale, heat-shaping technology, applied in the field of heat treatment of metal materials, can solve the problems of poor flatness, difficulty in reshaping, and high cost of sheet materials, and achieve high production efficiency, low requirements for annealing equipment and vacuum, and reprocessing The effect of simple shaping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

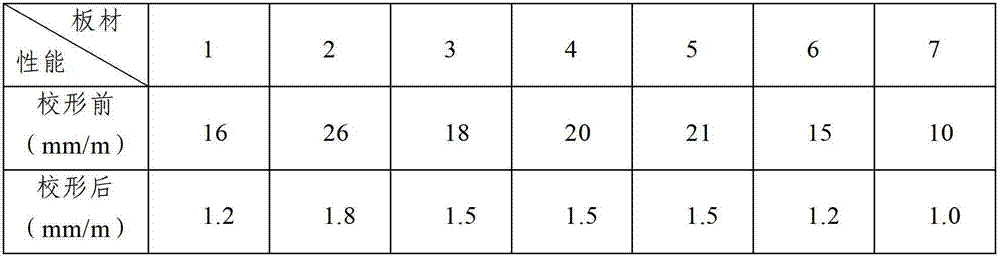

Embodiment 1

[0024] The thermal shaping method of the large-scale titanium sheet material of the present embodiment comprises the following steps:

[0025] Step 1. Place a piece of carbon steel material, 40mm thick and unevenness ≤ 3mm / m horizontally on the material tray in the pit annealing furnace, and then place 25 sheets with a thickness of 10mm and a width of 2100mm. Large-scale TA2 pure titanium plates with a length of 6000mm and an unevenness of 10mm / m to 26mm / m are neatly stacked on the correcting base plate, and an isolation backing plate is laid between the large-scale TA2 pure titanium plates during the stacking process , the specific process is: first stack 10 large-size TA2 pure titanium sheets to a thickness of 100mm, then lay a layer of isolation pad on the top layer of the stacked TA2 pure titanium sheets, and then stack 10 large-size TA2 pure titanium sheets in turn , one layer of isolation pads and 5 large-size TA2 pure titanium sheets, the stacking thickness of the large...

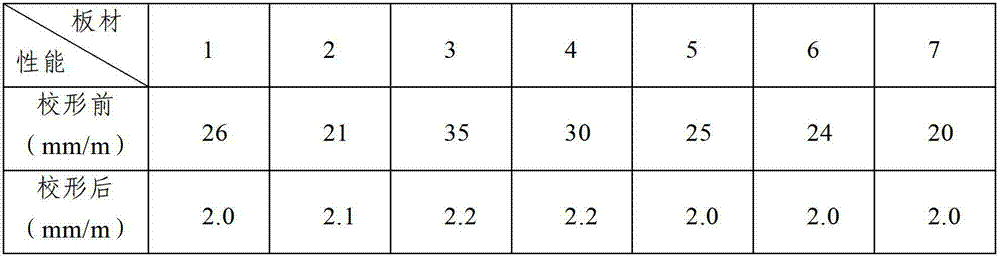

Embodiment 2

[0033] The thermal shaping method of the large-scale titanium sheet material of the present embodiment comprises the following steps:

[0034]Step 1. Horizontally place a piece of carbon steel on the tray in the trolley-type annealing furnace, with a thickness of 50mm and an unevenness ≤ 3mm / m, and then place 50 sheets with a thickness of 5mm and a width of 2500mm. The large-scale TC4 titanium alloy plates with a length of 7000mm and an unevenness of 20mm / m to 35mm / m are neatly stacked on the correcting base plate, and an isolation backing plate is laid between the large-scale TC4 titanium alloy plates during the stacking process , the specific process is: first stack 10 large-size TC4 titanium alloy plates to a thickness of 50mm, and then lay a layer of isolation pad on the top layer of the stacked TC4 titanium alloy plates, and then continue to stack large-scale TC4 titanium alloy plates and isolate Backing plate, the stacking thickness of large-size TC4 titanium alloy plate...

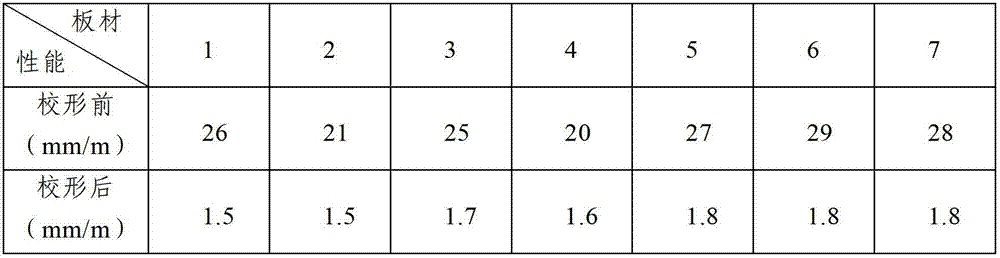

Embodiment 3

[0042] The thermal shaping method of the large-scale titanium sheet material of the present embodiment comprises the following steps:

[0043] Step 1. Place a piece of carbon steel material, 60mm thick and unevenness ≤ 3mm / m horizontally on the material tray in the pit annealing furnace, and then place 25 sheets with a thickness of 4mm and a width of 2000mm. Large-scale TA1 pure titanium plates with a length of 8000mm and an unevenness of 20mm / m to 29mm / m are neatly stacked on the correcting base plate. During the stacking process, an isolation backing plate is laid between the large-scale TA1 pure titanium plates , the specific process is: first stack 13 large-size TA1 pure titanium plates to a thickness of 52mm, then lay a layer of isolation pad on the top layer of the stacked TA1 pure titanium plate, and then continue to stack 12 sheets on the top of the isolation pad. Large size TA1 pure titanium plate, the material of the isolation backing plate is carbon steel, the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unevenness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com