A method and device for preparing r-t-b rare earth permanent magnets

A technology of rare earth permanent magnets and rare earth alloys, which is applied in the manufacture of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve problems such as high production costs, increased production efficiency and costs, and unqualified products, and achieve lower temperature zones The effect of uniformity requirements, improvement of operating efficiency, and improvement of furnace charging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method and device for preparing R-T-B rare-earth permanent magnets, specifically: the composition is Pr 5 Nd 5 Dy 60 Tb 5 Ho 5 Fe 10.5 B 5 co 1 Nb 1 Cu 0.5 Al 0.5 Ga 0.5 Zr 0.5 Ti 0.5 Rare earth alloy, the thickness of the alloy sheet is 0.3mm; put the alloy into the hydrogen crushing furnace for hydrogen crushing, the particle size of the powder after hydrogen crushing is less than 1mm; then, put the crushed alloy powder into the furnace body together with the R-T-B magnet A rotary diffusion device with a rotating speed of 10 rpm conducts thermal diffusion at a temperature of 950°C and a duration of 72h. Finally, an aging treatment was carried out at a temperature range of 600°C for 8 hours.

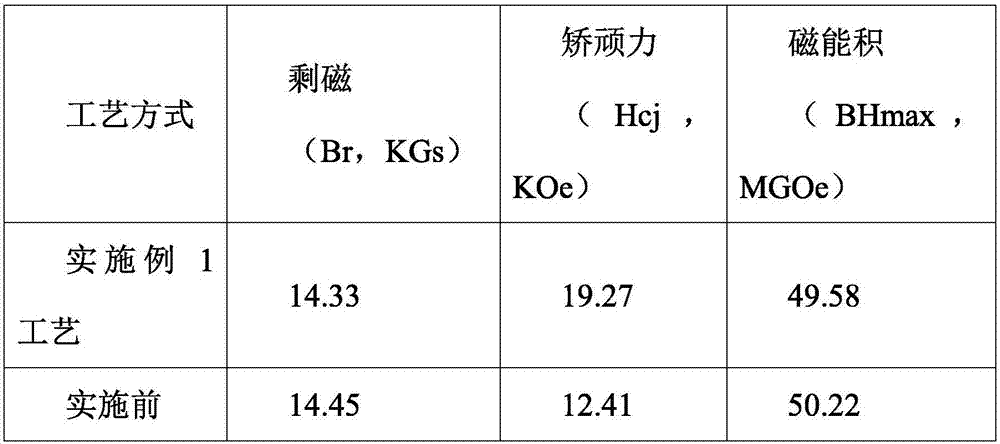

[0028] The magnetic properties of R-T-B rare earth permanent magnets before and after treatment are listed in Table 1 for comparison.

[0029]

[0030] Table 1 Comparison of magnetic properties of R-T-B rare earth permanent magnets before and after treatment

...

Embodiment 2

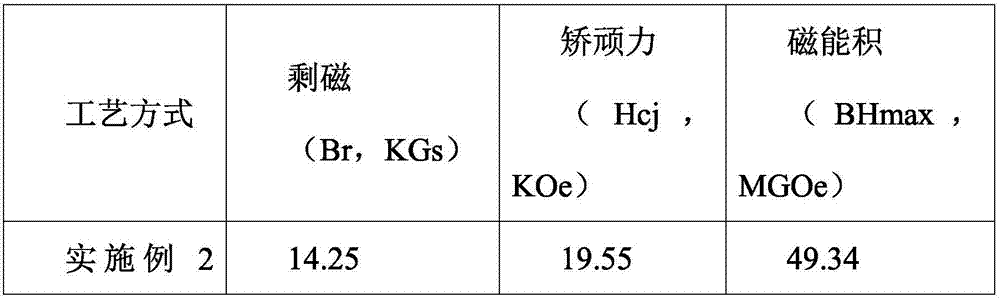

[0033] A method and device for preparing R-T-B rare earth permanent magnets, specifically: using ingot smelting to prepare the composition of Dy 60 Fe 35 B 5 Rare earth alloy, the thickness of the alloy sheet is 30mm; the alloy is put into a crusher for crushing, and the particle size of the crushed powder is less than 5mm; then, the crushed alloy powder is put into the furnace together with the R-T-B magnet and the speed is 1 revolution / min rotary diffusion device, simultaneously add steel balls with a diameter of 10mm and zirconia powder with a particle size of 3um, and carry out thermal diffusion at a temperature of 750°C and a duration of 72h. Finally, an aging treatment was carried out at a temperature range of 450°C for 2 hours. The magnetic properties of R-T-B rare earth permanent magnets before and after treatment are listed in Table 2 for comparison.

[0034]

[0035]

[0036] Table 2 Comparison of magnetic properties of R-T-B rare earth permanent magnets b...

Embodiment 3

[0039] A method and device for preparing R-T-B rare-earth permanent magnets, specifically: adopting quick-setting smelting to prepare Nd 5 Tb 50 Fe 35.5 B 5 co 1 Nb 1 Cu 0.5 Al 0.5 Ga 0.5 Zr 0.5 Ti 0.5 Rare earth alloy, the thickness of the alloy sheet is 5mm; the alloy is put into a crusher for crushing, and the particle size of the crushed powder is less than 5mm; then, the crushed alloy powder is put into the furnace together with the R-T-B magnet and the speed is 5 rpm / min rotary diffusion device, while adding dysprosium oxide powder with a particle size of 3um, conduct thermal diffusion at a temperature of 850°C and a duration of 24h. Finally, an aging treatment was carried out at a temperature range of 450°C for 6 hours. The magnetic properties of R-T-B rare earth permanent magnets before and after treatment are listed in Table 3 for comparison.

[0040]

[0041] Table 3 Comparison of magnetic properties of R-T-B rare earth permanent magnets before and af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com