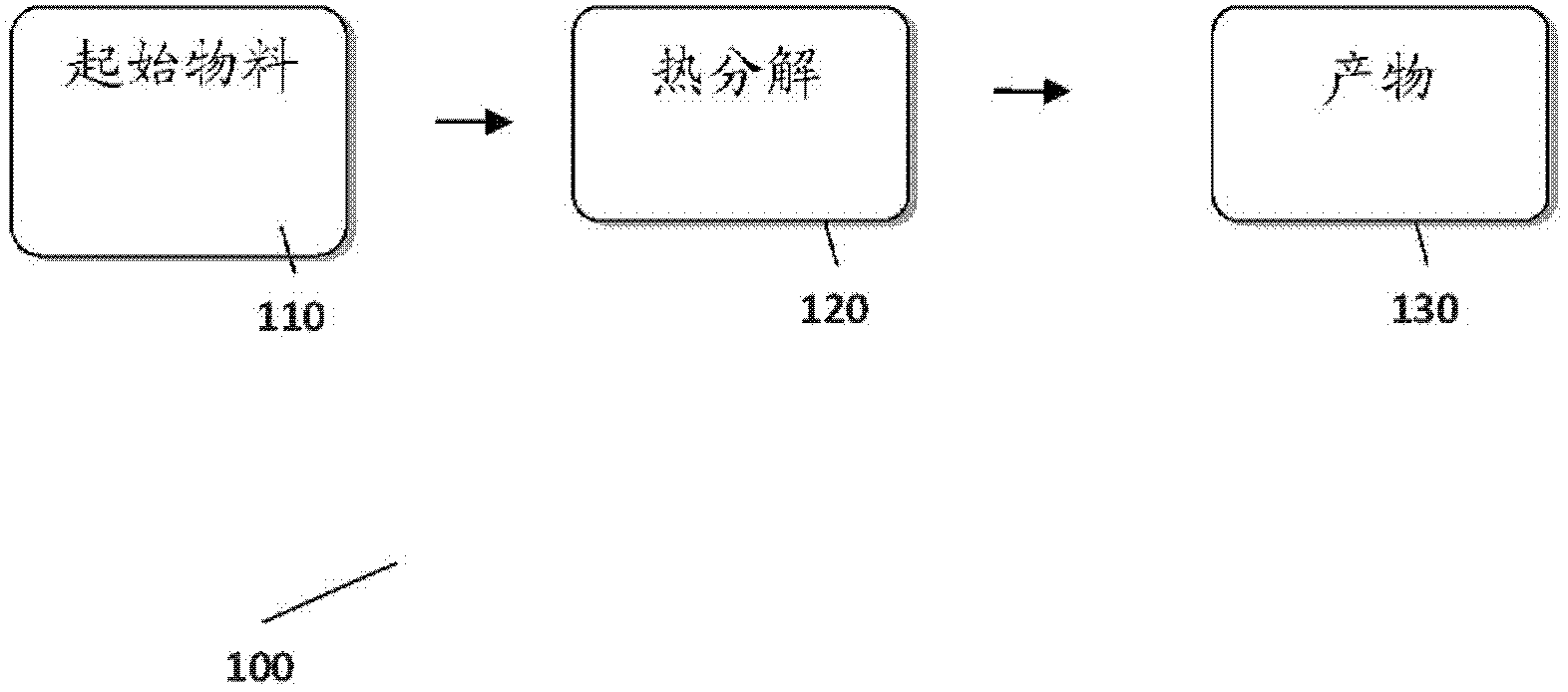

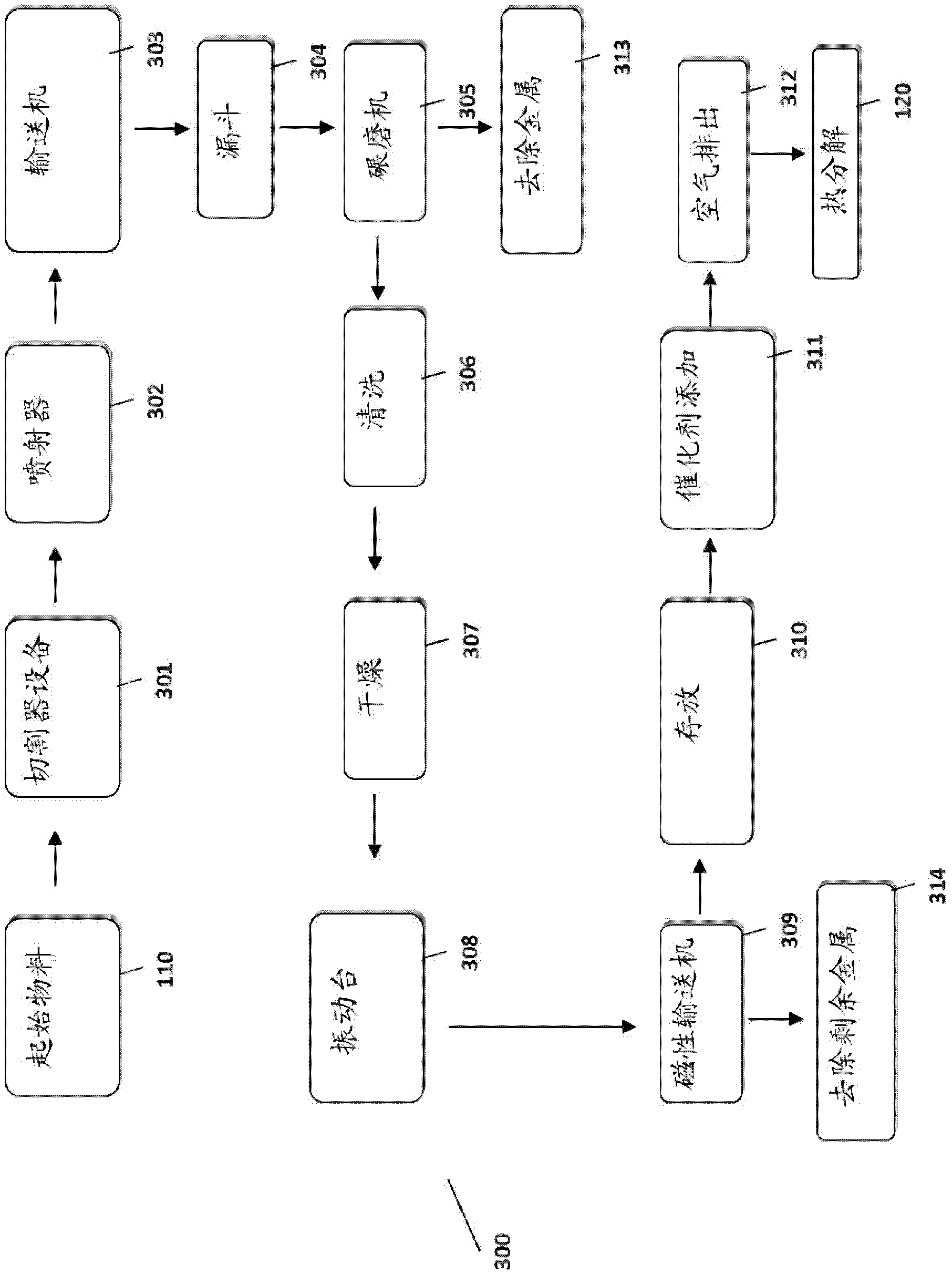

Method and installation for complete recycling through depolymerisation

A depolymerization and polymer technology, applied in recycling technology, plastic recycling, chemical recycling, etc., can solve problems such as residue damage and achieve high diesel output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0115] The following table shows the results obtained for different recycling methods using different starting materials:

[0116] 1.- Thermal decomposition of plastic or rubber without fillers: Yield: 98%

[0117]

[0118] 2.- Thermal decomposition of filled plastics: Yield: 98%

[0119]

[0120] 3.- Thermal decomposition of tires: Yield: 98%

[0121]

[0122] 4.- Thermal decomposition of oxidized oil: Yield: 96%

[0123]

[0124] From the results of the actual experiments carried out, it can be concluded that the method and apparatus advantageously produce more carbon black than originally present in the starting material. Car and truck tires (which are the most carbon black-rich tires) have the following carbon black composition: Car tires have 13% to 17% carbon black, while truck tires have between 25% and 30% carbon black. These amounts Varies depending on manufacturer. Thus, on average, tires undergoing recycling have a carbon black content of 20%. It ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com