Metal oxide/polyaniline composite resistor-type gas-sensitive element and preparation method thereof

A composite resistor and gas sensor technology, applied in the direction of material resistance, etc., can solve the problems of poor adhesion, shedding and restriction of gas sensor materials, and achieve the effects of low cost, short response time and short recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

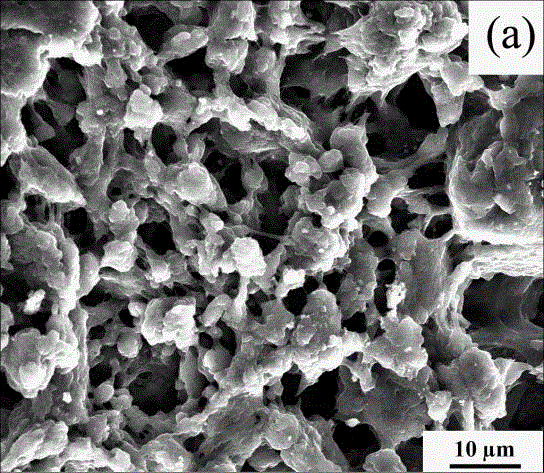

[0053] (1) Using solvent hot pressing method to prepare SnO 2 Porous nano-solid; SnO was prepared by solvent hot pressing method 2 Porous nanosolids; with SnO 2 Nano-powder is used as raw material and pore-forming agent 1,4-dioxane is ground to make a slurry, and the slurry is put into a solvent hot-pressed reaction kettle, and the temperature and pressure are kept at 150-250°C and 50-90MPa for 2 -5 hours, and then the autoclave is cooled to room temperature to obtain SnO 2 porous nanosolids;

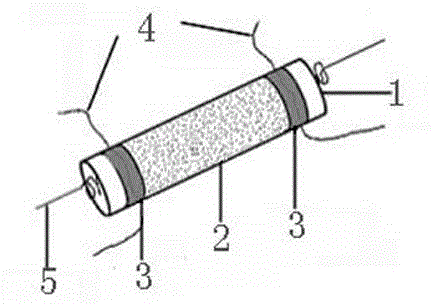

[0054] (2) SnO 2 Porous nano solids ground to 3-6μm, according to 1gSnO 2 The ratio of porous nano-solid to 2ml deionized water is made into a slurry; the slurry is coated on an aluminum oxide ceramic tube (i.e. substrate 1) with a gold electrode 3, a platinum lead 4, and a heating wire 5 inside; Then sinter the aluminum oxide ceramic tube coated with the slurry at a high temperature of 600-700°C, so that a layer of SnO with a thickness of 50-200 μm is attached to the aluminum oxid...

Embodiment 2

[0058] (1) Prepare SnO by the method in Example 1 2 porous nanosolids;

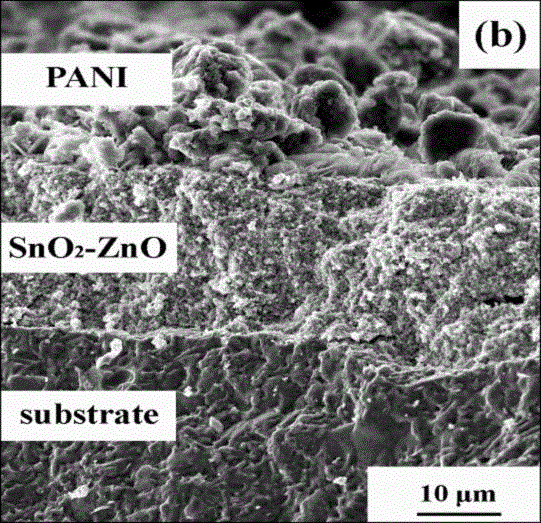

[0059] (2) SnO 2 Porous nano solids ground to 0.5-3μm, according to 1gSnO 2 The ratio of porous nano-solid to 2.5ml deionized water is made into a slurry; the slurry is coated on an aluminum oxide ceramic tube (ie substrate 1) with a gold electrode 3, a platinum lead 4, and a heating wire 5 inside ; Then sinter the aluminum oxide ceramic tube coated with the slurry at a high temperature of 600-700 ° C, so that a layer of SnO with a thickness of 10-200 μm is attached to the aluminum oxide ceramic tube 2 porous thick film;

[0060] (3) Grind polyaniline to 10-100 μm, fully dissolve polyaniline in a mixed solvent of N-methylpyrrolidone (NMP) and deionized water according to the ratio of 1g:15ml (N-methylpyrrolidone and deionized water The molar ratio is 10:1), and then evenly coated with the SnO obtained in step (2) 2 On the porous thick film, let it dry naturally for 24 hours until the solvent evapo...

Embodiment 3

[0063] (1) Prepare SnO by the method in Example 1 2 porous nanosolids;

[0064] (2) SnO 2 Porous nano-solid ground to 6-9μm, according to 1gSnO 2 The ratio of porous nano-solid to 1.5ml deionized water is made into a slurry; the slurry is coated on an aluminum oxide ceramic tube (that is, a substrate 1) with a gold electrode 3, a platinum lead 4, and a heating wire 5 inside ; Then sinter the aluminum oxide ceramic tube coated with the slurry at a high temperature of 600-700 ° C, so that a layer of SnO with a thickness of 50-300 μm is attached to the aluminum oxide ceramic tube 2 porous thick film;

[0065] (3) Grind polyaniline to 10-100 μm, fully dissolve polyaniline in a mixed solvent of N-methylpyrrolidone (NMP) and deionized water according to the ratio of 1g:5ml (N-methylpyrrolidone and deionized water The molar ratio is 4:1), and then evenly coated with the SnO obtained in the above step (2) 2 On the porous thick film, let it dry naturally for 24 hours until the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com