Metal oxide/polyaniline composite resistor-type gas-sensitive element and preparation method thereof

A technology of gas-sensing components and composite resistors, applied in the direction of material resistance, etc., can solve the problems of poor adhesion, gas-sensing material falling off, limitation, etc., and achieve the effects of low cost, short response time, and short recovery time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

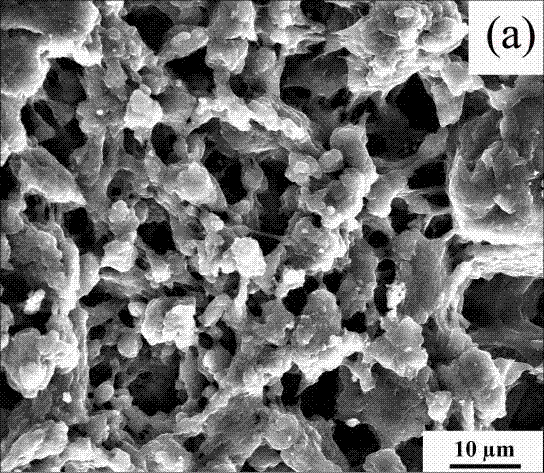

[0053] (1) Using solvent hot pressing method to prepare SnO 2 Porous nano-solid; SnO was prepared by solvent hot pressing method 2 Porous nanosolids; with SnO 2 Nano-powder is used as raw material and pore-forming agent 1,4-dioxane is ground to make a slurry, and the slurry is put into a solvent hot-pressed reaction kettle, and the temperature and pressure are kept at 150-250°C and 50-90MPa for 2 -5 hours, and then the autoclave is cooled to room temperature to obtain SnO 2 porous nanosolids;

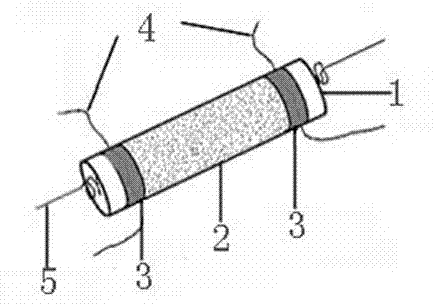

[0054] (2) SnO 2 Porous nano solids ground to 3-6μm, according to 1gSnO 2 The ratio of porous nano-solid to 2ml deionized water is made into a slurry; the slurry is coated on an aluminum oxide ceramic tube (i.e. substrate 1) with a gold electrode 3, a platinum lead 4, and a heating wire 5 inside; Then sinter the aluminum oxide ceramic tube coated with the slurry at a high temperature of 600-700°C, so that a layer of SnO with a thickness of 50-200 μm is attached to the aluminum oxid...

Embodiment 2

[0058] (1) Prepare SnO by the method in Example 1 2 porous nanosolids;

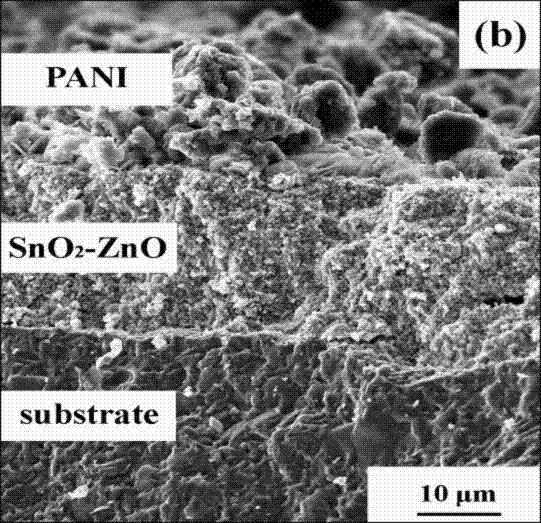

[0059] (2) SnO 2 Porous nano solids ground to 0.5-3μm, according to 1gSnO 2 The ratio of porous nano-solid to 2.5ml deionized water is made into a slurry; the slurry is coated on an aluminum oxide ceramic tube (ie substrate 1) with a gold electrode 3, a platinum lead 4, and a heating wire 5 inside ; Then sinter the aluminum oxide ceramic tube coated with the slurry at a high temperature of 600-700 ° C, so that a layer of SnO with a thickness of 10-200 μm is attached to the aluminum oxide ceramic tube 2 porous thick film;

[0060] (3) Grind polyaniline to 10-100 μm, fully dissolve polyaniline in a mixed solvent of N-methylpyrrolidone (NMP) and deionized water according to the ratio of 1g:15ml (N-methylpyrrolidone and deionized water The molar ratio is 10:1), and then evenly coated with the SnO obtained in step (2) 2 On the porous thick film, let it dry naturally for 24 hours until the solvent evapora...

Embodiment 3

[0063] (1) Prepare SnO by the method in Example 1 2 porous nanosolids;

[0064] (2) SnO 2 Porous nano-solid ground to 6-9μm, according to 1gSnO 2 The ratio of porous nano-solid to 1.5ml deionized water is made into a slurry; the slurry is coated on an aluminum oxide ceramic tube (that is, a substrate 1) with a gold electrode 3, a platinum lead 4, and a heating wire 5 inside ; Then sinter the aluminum oxide ceramic tube coated with the slurry at a high temperature of 600-700 ° C, so that a layer of SnO with a thickness of 50-300 μm is attached to the aluminum oxide ceramic tube 2 porous thick film;

[0065] (3) Grind polyaniline to 10-100 μm, fully dissolve polyaniline in a mixed solvent of N-methylpyrrolidone (NMP) and deionized water according to the ratio of 1g:5ml (N-methylpyrrolidone and deionized water The molar ratio is 4:1), and then evenly coated with the SnO obtained in the above step (2) 2 On the porous thick film, let it dry naturally for 24 hours until the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com