Garbage drying device

A drying device and garbage technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of inconvenient entry and exit of garbage, inability to process, large energy consumption, etc., achieve convenient and simple garbage input and discharge, improve the effect and The effect of high efficiency and large amount of garbage drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

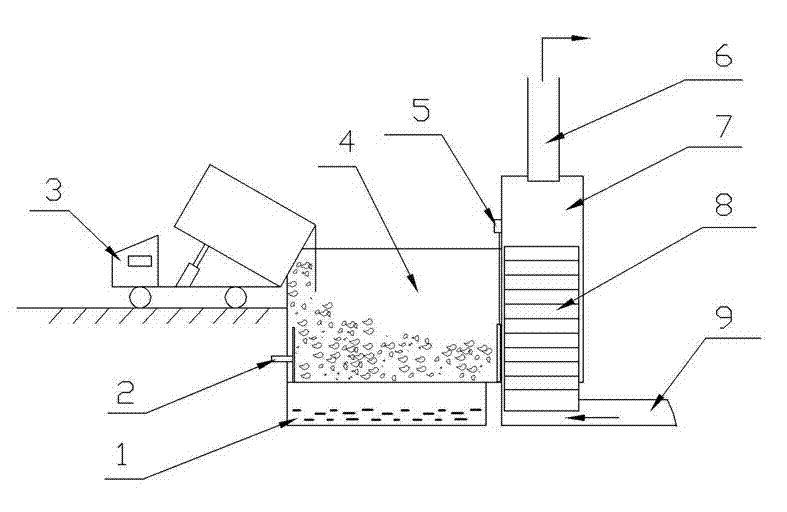

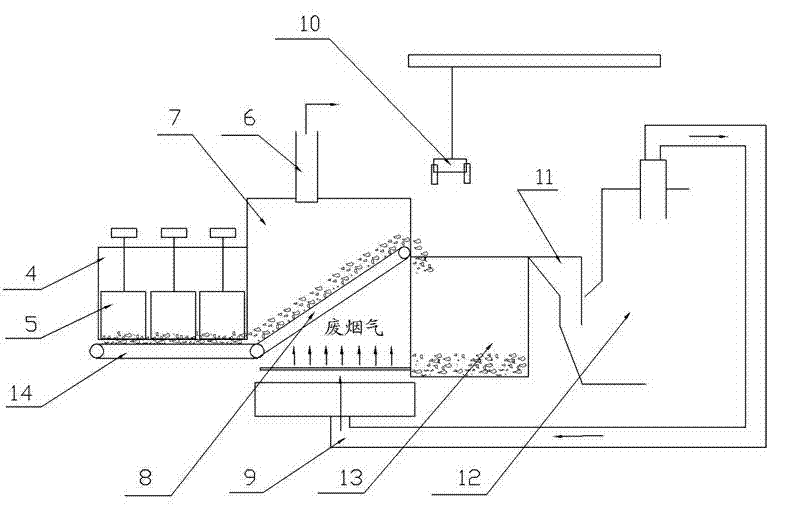

[0019] As shown in the attached figure, it is a garbage drying device, especially a device for effectively drying garbage by using waste gas from garbage incineration. Including garbage infiltration tank 1, garbage extrusion device 2, garbage pool 4, valve 5, smoke exhaust pipe 6, drying bin 7, upper conveyor belt 8, horizontal conveyor belt 14, incineration flue gas pipeline 9, garbage crane grab Bucket 10, incinerator garbage feed port 11, garbage incinerator 12, dry garbage storage bin 13.

[0020] In this embodiment, the garbage infiltration tank 1 is arranged below the garbage tank 4, and the bottom of the garbage tank 4 is a metal mesh, so that the garbage washing and squeezing filtrate can be easily dropped into the garbage infiltration tank 1, and the leachate is environmentally friendly. Utilize or discharge after treatment.

[0021] In this embodiment, a garbage extruding device 2 is provided at one end of the garbage inlet of the garbage pool 4 of the garbage dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com